Blast furnace cooling water temperature adjustment device and control method in oven state

A temperature regulating device and cooling water technology, applied in the direction of cooling device, etc., can solve the problems of poor discharge, retention of crystallization water on the hot surface, etc., and achieve the effect of prolonging the service life, reducing the pressure shock, and increasing the diameter of the conduit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

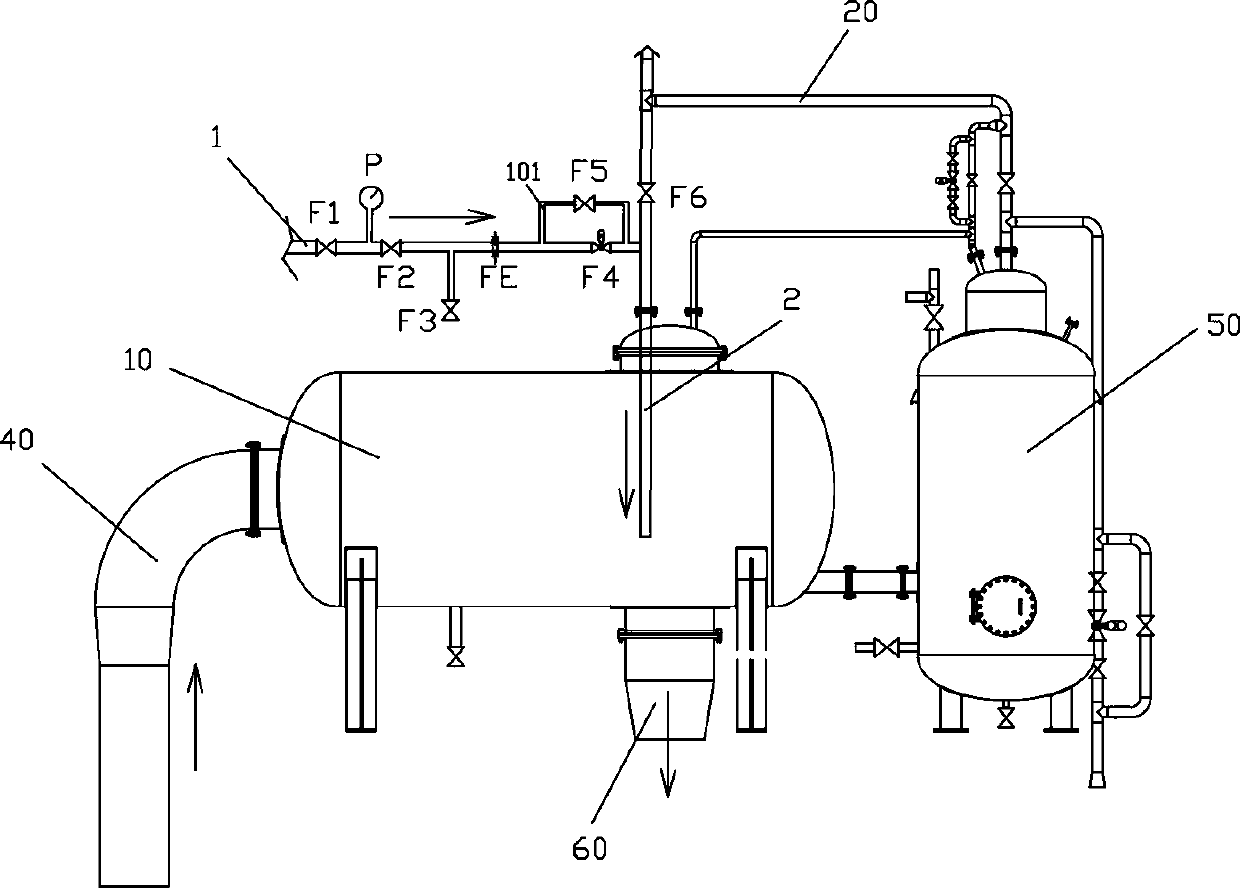

[0045] The operating process of cooling water temperature control regulation of the present invention is as follows:

[0046] 1) The valves of the thermostat are all closed;

[0047]2) Open the drain valve;

[0048] 3) Slowly open the manual shut-off valve. When the opening reaches 5%, observe that steam is discharged from the drain valve, preheat the device and observe whether the steam is unblocked;

[0049] 4) After the steam discharge of the blowdown valve is unblocked, confirm whether there is any change in the pointer of the pressure gauge, and then carry out pressure control by adjusting the pressure reducing valve until the pressure gauge is controlled at 5kg;

[0050] 5) Open the bypass valve, gradually close the drain valve to the fully closed position, observe the flow change of the flow meter, and then slowly open the manual shut-off valve to an opening of 20-40%;

[0051] 6) After the flow rate of the flowmeter is stable, the manual opening of the pneumatic cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com