Sulfurous method sugar refining segmented preliming clarifying process

A sulfurous acid method and process technology, which is applied in sucrose production, sugar production, and sugar juice purification, etc., can solve the problems of low energy consumption, poor product quality, and low clarification efficiency in the sugar recovery process, and achieve the improvement of the purity of clear juice , reduce evaporation fouling, improve the effect of sugar recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

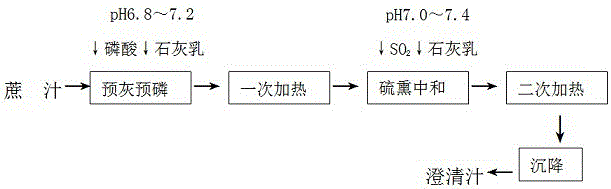

[0027] Embodiment 1: as figure 1 As shown, the traditional sulfurous acid clarification process is used to treat sugarcane juice. The process is as follows: sugarcane is used as raw material, and sugarcane juice is obtained after crushing, squeezing and extracting juice. After primary heating, add sulfur dioxide and lime milk to obtain neutralized juice. After secondary heating, the neutralized juice enters the sedimentation tank for sedimentation and separation to obtain clarified juice, which is the main raw material for the production of white sugar. The clarification process indicators are: the total value of added phosphoric acid is 400ppm, the pH value of prelime juice is 7.2, the primary heating temperature is 65°C, the sulfur fumigation intensity of sugarcane juice is 24CC, the neutralization pH value of sugarcane juice is 7.2, and the secondary heating temperature is 100°C.

[0028] The detection result of embodiment 1 is as follows:

[0029] Continuously collect and...

Embodiment 2

[0030] Embodiment 2: as figure 2 As shown, the sugarcane juice obtained by pressing and extracting juice is clarified by adopting the subsection pre-ash clarification process of sugar production by sulfite method of the present invention, and the specific implementation steps are as follows:

[0031] a) Pre-lime and pre-phosphorus: sugarcane juice is obtained after the sugarcane is squeezed and extracted, and phosphoric acid and milk of lime are added to the sugarcane juice at the same time to make the pH of the sugarcane juice 7.2;

[0032] b) Primary heating: the sugarcane juice is pre-ashed and pre-phosphorused and then sent to the heater for primary heating, and the heating temperature is controlled at 65°C;

[0033] c) Secondary pre-ashing: the cane juice is heated once and sent to the sulfur fumigation neutralizer for sulfur fumigation neutralization; lime milk is added before the sulfur fumigation neutralization, so that the pH of the cane juice is 8.2;

[0034] d) Su...

Embodiment 3

[0040] Example 3: The sugarcane juice obtained by squeezing and extracting juice is also clarified by using the sulfite method sugar production segmental pre-ash clarification process of the present invention. The operation steps and parameters are basically the same as those in Example 2. The only difference is: step c) The pH value of the sugar cane juice is 8.5.

[0041] The detection result of embodiment 3 is as follows:

[0042] Continuously collect cane juice and clarified juice samples for 2 hours, and test and analyze the purity of cane juice, clarified juice, color value, and pH value. The results are: the purity of cane juice is 83.02AP, the purity of clarified juice is 85.23AP, the color value of clarified juice is 53.11°st, and the pH value of clarified juice is 7.21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com