Solar heat collection and auto heating-based outdoor biomass thermal cracking oil refining device

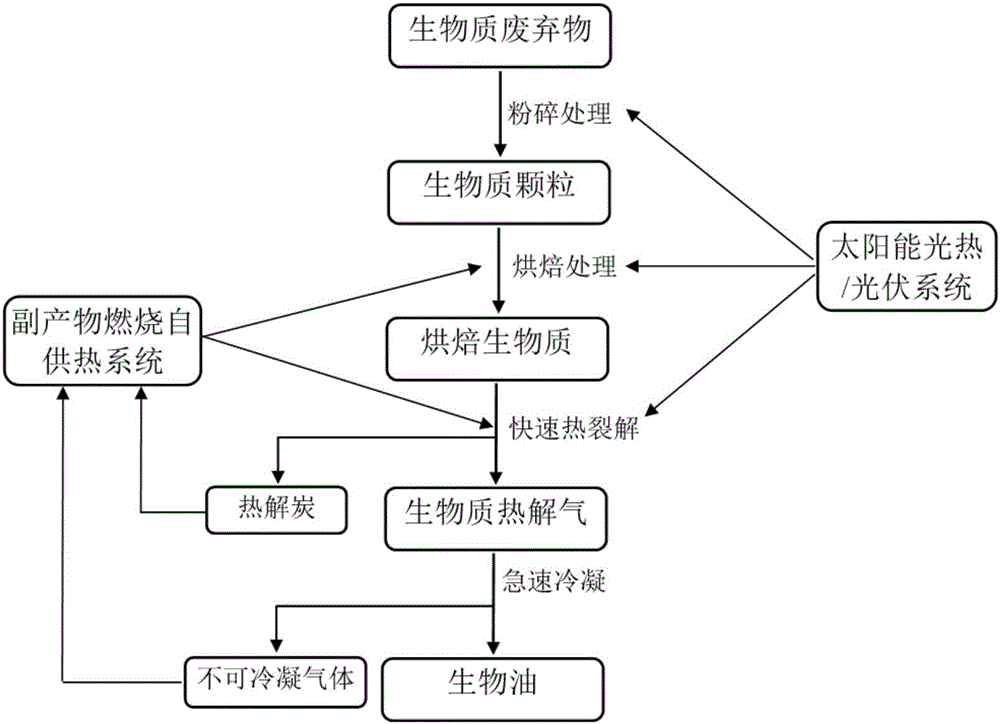

A biomass thermal cracking and solar heat collection technology, applied in solar thermal devices, solar thermal collectors, solar thermal energy and other directions, can solve the problems of low yield of high-value bio-oil, catalyst coking, expensive catalysts, etc. The effect of reducing oxygen content, increasing calorific value, and cleaning biomass refining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Adopt the device of the present invention to carry out thermal cracking oil refining with poplar branches and branches as raw materials in the forest farm or landscaping waste treatment center, and the properties of the poplar bio-oil product obtained are: carbon content 58%, oxygen content 34%, high calorific value 29MJ / Kg , moisture content 19%, pH value 3.6.

[0034] Using the device of the present invention to use corn stalks as raw materials for thermal cracking and refining in farms or fields, the properties of the obtained corn stalk bio-oil products are: carbon content 57%, oxygen content 36%, high calorific value 26MJ / Kg, moisture content 23%, pH 3.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com