A kind of polyester composition and its preparation method and application

A composition and polyester technology, which are applied in the field of polyester compositions and their preparation, can solve the problems of insignificant regeneration inhibition effect of oligomer cyclic trimer, reduced content, and difficulty in execution, and achieve good regeneration inhibition effect. , Industrial simplicity, good hydrolysis resistance and heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

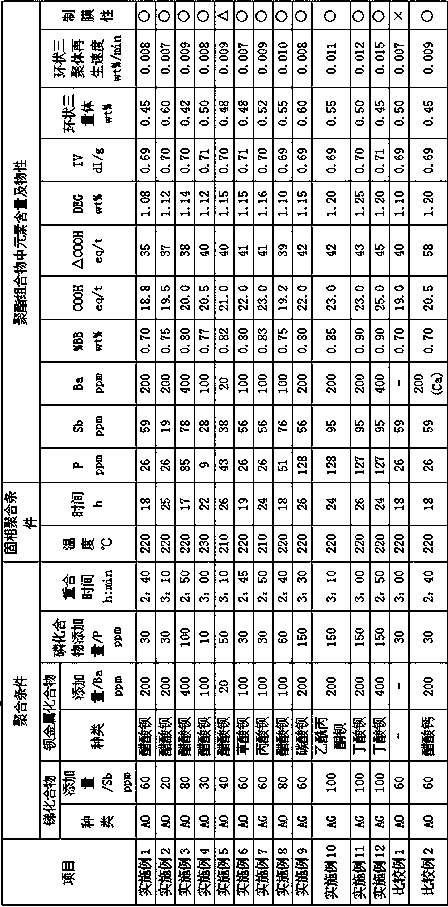

Examples

Embodiment 1

[0064] At a temperature of 250°C, 166 parts by weight of PTA and 71.3 parts by weight of EG were added to the esterification reactor, and the esterification reaction was carried out under normal pressure. When the esterification reaction was completed, the temperature in the esterification kettle was 250°C, Fractionate water to obtain small molecular polymers.

[0065] Add catalyst AO equivalent to 60 ppm by weight of the polyester composition in terms of antimony element, barium acetate equivalent to 200 ppm by weight of the polyester composition in terms of metal barium element, and equivalent to the polyester composition in terms of phosphorus element. The stabilizer PA with a weight of 30 ppm starts to depressurize and heat up after 5 minutes, the pressure is reduced to about 300 Pa after 1 hour, and the temperature rises to 290°C after 1.5 hours; when the polycondensation reaction is over, the pressure in the reactor is about 200 Pa. The obtained polymer was solid-phase poly...

Embodiment 2

[0068] At a temperature of 250°C, 166 parts by weight of PTA and 71.3 parts by weight of EG were added to the esterification reactor, and the esterification reaction was carried out under normal pressure. When the esterification reaction was completed, the temperature in the esterification kettle was 250°C, Fractionate water to obtain small molecular polymers.

[0069] Add catalyst AO equivalent to 20 ppm by weight of polyester composition based on antimony element, barium acetate equivalent to 200 ppm by weight of polyester composition based on metal barium element, and equivalent to polyester composition based on phosphorus element. The stabilizer PA with a weight of 30 ppm starts to depressurize and heat up after 5 minutes, the pressure is reduced to about 300 Pa after 1 hour, and the temperature rises to 290°C after 1.5 hours; when the polycondensation reaction is over, the pressure in the reactor is about 200 Pa. The obtained polymer was solid-phase polymerized at 220°C for ...

Embodiment 3

[0071] At a temperature of 250°C, 166 parts by weight of PTA and 71.3 parts by weight of EG were added to the esterification reactor, and the esterification reaction was carried out under normal pressure. When the esterification reaction was completed, the temperature in the esterification kettle was 250°C, Fractionate water to obtain small molecular polymers.

[0072] Add catalyst AO equivalent to 80 ppm by weight of the polyester composition in terms of antimony element, barium acetate equivalent to 400 ppm by weight of the polyester composition in terms of metal barium element, and equivalent to the polyester composition in terms of phosphorus element. The stabilizer PA with a weight of 100ppm starts to depressurize and heat up after 5 minutes, the pressure is reduced to about 300 Pa after 1 hour, and the temperature rises to 290°C after 1.5 hours; when the polycondensation reaction is over, the pressure in the reactor is about 200 Pa. The obtained polymer was further solid-ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com