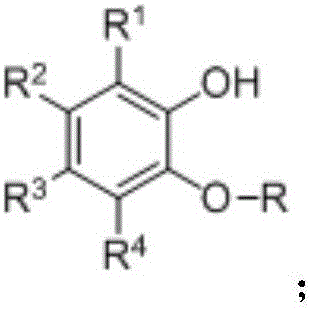

Ether bond rupturing method for ortho-hydroxyl phenyl alkyl ether

A technology of o-hydroxyphenyl alkyl ether and hydroxyphenyl alkyl ether, which is applied in the field of intermediate synthesis of pharmaceuticals and chemical raw materials, can solve the problems of affecting the yield and low yield of eugenol demethylation reaction, and achieves Wide application range and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 (eugenol demethylation)

[0031]

[0032] Add iodine (12.727g), aluminum powder (1.902g) and acetonitrile (100ml) respectively to a 250ml eggplant-shaped bottle, heat to reflux, and stir for 2 hours until the purple color of iodine disappears. Further pyridine (12.183 g) and eugenol (4.919 g) were added, and the reaction was continued for 18 hours. Stirring was stopped, and after cooling to room temperature, 2mol / L dilute hydrochloric acid (50ml) was added to the reaction solution to acidify it, and extracted with ethyl acetate (50ml×4). The organic phases were combined and dried over anhydrous sodium sulfate. Filtration, the filtrate was evaporated to dryness with a rotary evaporator, and the residue was purified by flash column chromatography (mobile phase was ethyl acetate:petroleum ether=1:4, volume ratio) to obtain 4-allyl catechol (white solid , 4.910 g, yield 99%).

[0033] 1H NMR (400MHz, CDCl3) δ6.80(d, J=8Hz, 1H), 6.72(d, J=2Hz, 1H), 6.63(dd...

Embodiment 2

[0035] Embodiment 2 (eugenol demethylation)

[0036]

[0037] Add iodine (2.098g), aluminum powder (0.362g) and acetonitrile (50ml) respectively to a 100ml eggplant-shaped bottle, heat to reflux, and stir for 2 hours until the purple color of iodine disappears. Additional DMAP (2.750 g) and eugenol (0.825 g) were added and the reaction was continued for 18 hours. Stop stirring, cool to room temperature, add 2mol / L dilute hydrochloric acid (10ml) to the reaction solution to acidify, and extract with ethyl acetate (50ml×3). The organic phases were combined and dried over anhydrous sodium sulfate. Filtration, the filtrate was evaporated to dryness with a rotary evaporator, and the residue was purified by flash column chromatography (mobile phase was ethyl acetate:petroleum ether=1:4, volume ratio) to obtain 4-allyl catechol (white solid , 0.362g, yield 48%), and recovered starting material (0.202g).

Embodiment 3

[0038] Embodiment 3 (eugenol demethylation)

[0039]

[0040]Add iodine (2.107g), aluminum powder (0.409g) and acetonitrile (50ml) respectively to a 100ml eggplant-shaped bottle, heat to reflux, and stir for 2 hours until the purple color of iodine disappears. Further 2,6-lutidine (2.750 g) and eugenol (0.823 g) were added, and the reaction was continued for 18 hours. Stop stirring, cool to room temperature, add 2mol / L dilute hydrochloric acid (10ml) to the reaction solution to acidify, and extract with ethyl acetate (50ml×3). The organic phases were combined and dried over anhydrous sodium sulfate. Filtration, the filtrate was evaporated to dryness with a rotary evaporator, and the residue was purified by flash column chromatography (mobile phase was ethyl acetate:petroleum ether=1:4, volume ratio) to obtain 4-allyl catechol (white solid , 0.692g, yield 92%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com