Three-phase conductive composite material, preparation method and application

A conductive composite material, three-phase technology, applied in the direction of conductive materials, conductive materials, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of inability to improve the electrical conductivity of composite materials, reduce mechanical properties, etc., and achieve good compression Sensitivity and electro-thermal properties, low cost, excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Another embodiment of the present invention provides a method for preparing a carbon nanotube / water-based polypyrrole / cement three-phase conductive composite material, comprising the following steps: (1) weighing the purified pyrrole monomer in a round bottom flask, adding Sodium lignosulfonate aqueous solution, under the condition of stirring in an ice-water bath, add FeCl dropwise 3 Aqueous solution, reacted at room temperature for 8-12 hours, filtered, dried, and ground to make water-based polypyrrole; (2) dissolve the water-based polypyrrole prepared in step (1) in distilled water, and add to the Portland-containing In the clean paddle mixer of 425 cement and purified carbon nanotubes, stir at a slow speed for 120 seconds, then pause for 15 seconds and turn to medium and high speed for 120 seconds; (3) pour the stirred cement-based composite material into the mold, and vibrate , steam curing and other processes to make carbon nanotube / polypyrrole / cement three-phase ...

Embodiment 1

[0032] (1) Measure 0.5 mL of purified pyrrole monomer into a 250 mL round bottom flask, add 5 mL of 1 mol / L sodium lignosulfonate aqueous solution, and add 1 mol / L of FeCl dropwise under stirring in an ice-water bath 3 5mL of aqueous solution, reacted at room temperature for 8 hours, then filtered, dried, and ground to make water-based polypyrrole;

[0033](2) Dissolve the water-based polypyrrole prepared above in 10 mL of distilled water, add 1300 g of Portland 425 cement and 0.8 g of purified carbon nanotubes to a clean paddle stirrer, stir at a slow speed for 120 seconds, then pause for 15 seconds and turn to medium Stir at high speed for 120 seconds;

[0034] (3) Pouring the stirred cement-based composite material into a mold, and through processes such as vibration and steam curing, a carbon nanotube / water-based polypyrrole / cement three-phase conductive composite material is produced.

Embodiment 2

[0036] (1) Measure 0.8 mL of purified pyrrole monomer in a 250 mL round bottom flask, add 5 mL of 1.5 mol / L sodium lignosulfonate aqueous solution, and add 1.5 mol / L of FeCl dropwise under stirring in an ice-water bath 3 5mL of aqueous solution, reacted at room temperature for 10 hours under stirring conditions, and made water-based polypyrrole through suction filtration, drying and grinding;

[0037] (2) Dissolve the water-based polypyrrole prepared above in 10 mL of distilled water, add 1300 g of Portland 425 cement and 0.8 g of purified carbon nanotubes to a clean paddle stirrer, stir at a slow speed for 120 seconds, then pause for 15 seconds and turn to medium Stir at high speed for 120 seconds;

[0038] (3) Pouring the stirred cement-based composite material into a mold, and through processes such as vibration and steam curing, a carbon nanotube / water-based polypyrrole / cement three-phase conductive composite material is produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

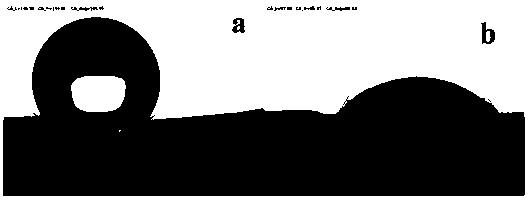

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com