Brickmaking technique for deeply processing waste steel slag

A technology for deep processing and scrap steel slag is applied in the field of deep processing of scrap steel slag for brick making, which can solve the problems of low utilization rate and low economic benefit, and achieve the effects of high economic benefit, reasonable process, economic benefit, environmental protection and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

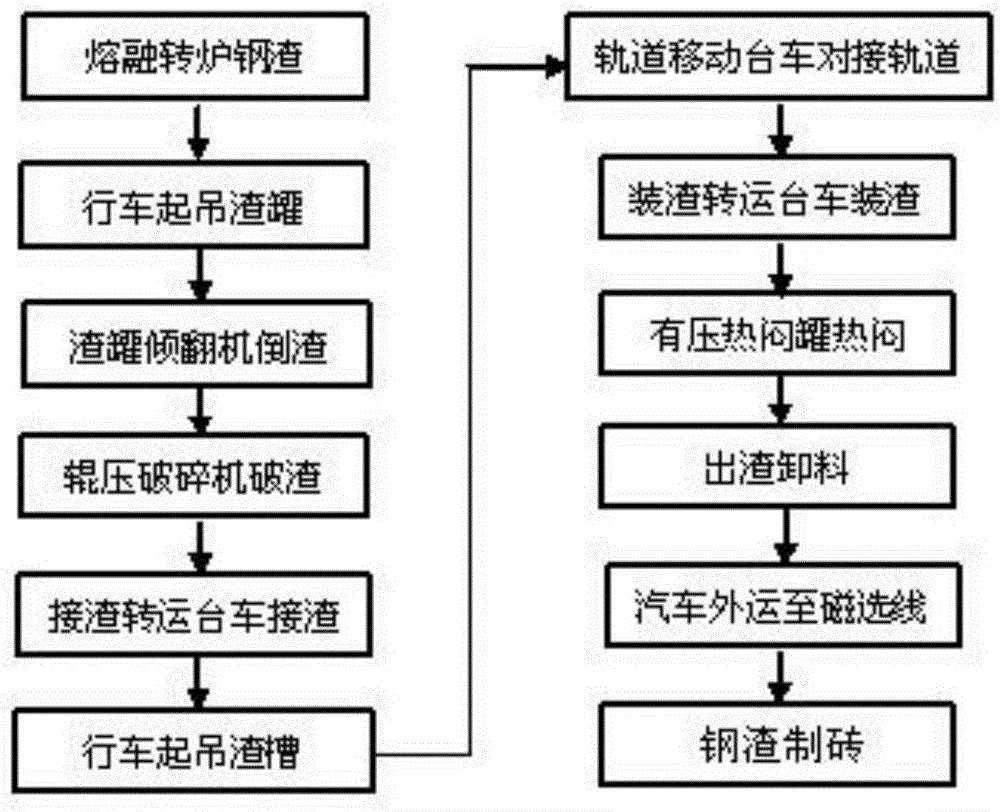

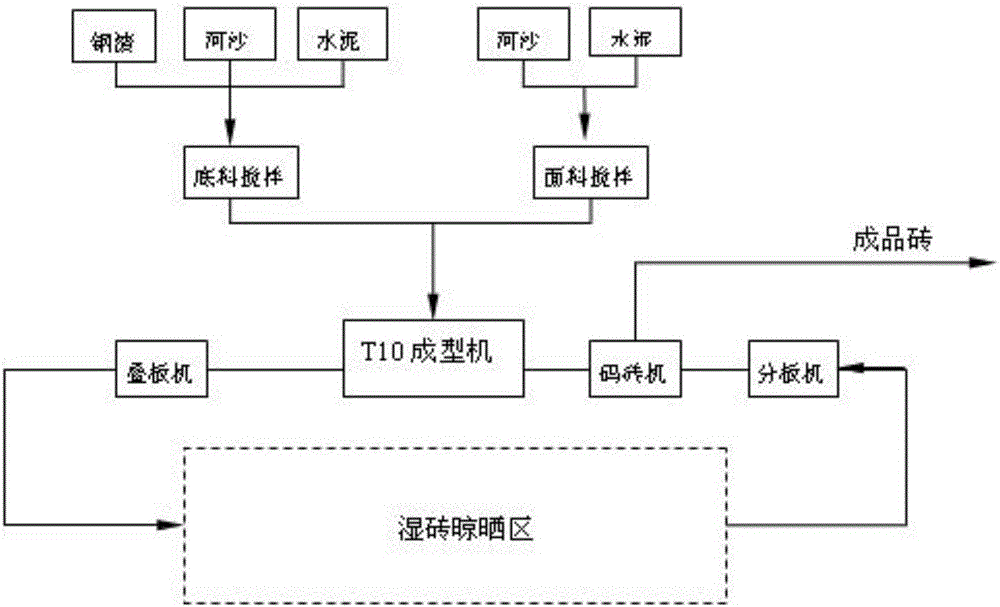

[0021] A brick-making process of deep processing of waste steel slag, including two processes of hot-smelling steel slag treatment and steel slag brick-making. The specific process steps are as follows:

[0022] (1) Incoming slag: the steelmaking workshop pours molten converter steel slag into the slag tank, and the slag tank is transported to the slag-span workshop by a straddle truck;

[0023] (2) Lifting and transporting the slag tank by driving: the crane in the slag crossing workshop lifts the slag containing slag tank and places it in the slag tank tipping machine;

[0024] (3) Slag dumping by the slag tank tipping machine: the slag tank tipping machine transports the slag tank to the predetermined slag dumping area for dumping and dumping. Lift the empty slag tank and return to the steelmaking workshop for slag discharge;

[0025] (4) Roller crusher breaks slag: Roller crusher performs multiple roll crushing to crush steel slag, interspersed with water spray cooling op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com