Automatic breaking device for optical glass plate material

A glass plate and optical technology, applied in glass cutting devices, glass manufacturing equipment, glass transportation equipment, etc., can solve the problems of difficult operation, inaccurate position control, easy damage to glass and clamping devices, etc., to achieve accurate control, The effect of good cross-section quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

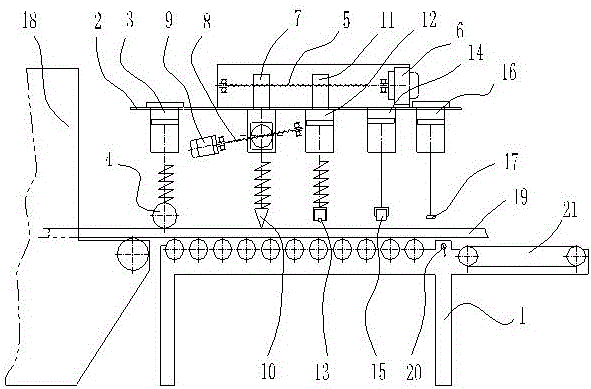

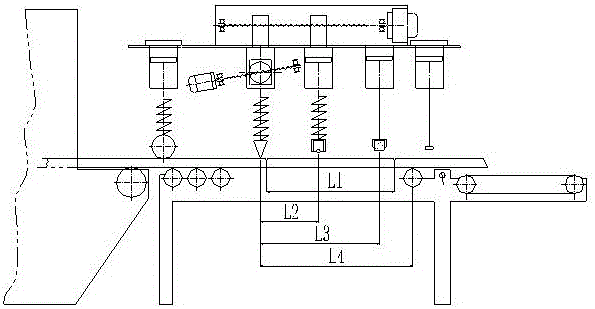

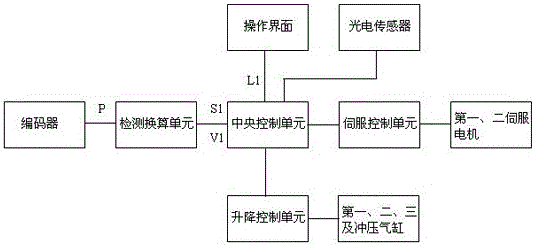

[0024] Such as figure 1 As shown, the automatic cutting device for optical glass sheets of the present invention includes a transmission mechanism, a longitudinal movement mechanism, a detection mechanism, a scribing mechanism, a heating mechanism, a cooling mechanism, a pressure breaking mechanism and a control system. in,

[0025] The transmission mechanism includes a roller conveying platform 1 and a belt conveyor 21 installed at the tail of the mesh belt traction furnace 18, and a photoelectric sensor 20 is installed at the rear of the roller conveying platform 1, which is used for guiding and conveying the process of cutting the optical glass plate;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com