Furnace body of activated carbon activation furnace

A technology of activation furnace and activated carbon, which is applied in the direction of furnace, rotary drum furnace, furnace type, etc., which can solve the problems of increased ablation, unstable gas pressure, and the inability to further significantly increase the production capacity of activated carbon, so as to increase the number and time of contact , The thickness of the material layer is moderate and reasonable, and the effect of the best activation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

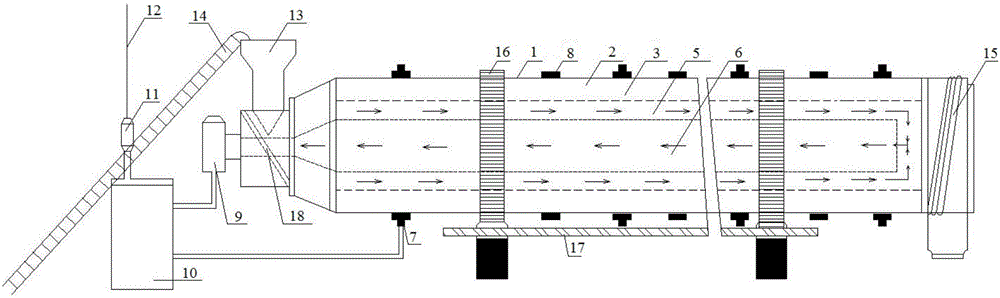

[0033] refer to figure 1 with figure 2 , the activated carbon activation furnace of the present embodiment comprises a body of furnace, a material furnace inlet device 13 and a discharge mechanism 15, the material furnace inlet device 13 is communicated with the feed port of the furnace body, and the discharge mechanism 15 is communicated with the discharge port of the furnace body The furnace body is provided with a combustion passage 6 communicating with the interior of the furnace body. Air is passed through the combustion passage 6. The interior of the furnace body is in a negative pressure state and the air pressure in the combustion passage 6 is lower than that of the furnace body.

[0034] With the current level of technology and methods, the areas in the furnace body cannot be completely relatively sealed, so the combustible gas precipitated by the heating of the material is easy to burn directly in the area where the material is placed, resulting in a large increase ...

Embodiment 2

[0049] refer to image 3 , the activated carbon activation furnace of the present embodiment, its structure is basically the same as that of embodiment 1, further:

[0050] In this embodiment, each compartment support 4 includes a compartment support column 401 and a compartment support plate 402, one end of the compartment support column 401 is connected to the inner wall of the outer cylinder 1, and the other end of the compartment support column 401 is connected to the compartment support plate 402. The warehouse supporting plate 402 is connected, and the sub-bin supporting plate 402 is an arc-shaped plate. The sub-bin supporting plate 402 arranged along the circumferential direction encloses a combustion channel 6 with a circular radial cross-section at the center position inside the furnace body. A part of a material channel 5 is enclosed between two adjacent sub-compartment support columns 401, the inner wall of the outer cylinder 1 and the outer wall of the combustion c...

Embodiment 3

[0056] refer to Figure 4 , the active carbon activation furnace of the present embodiment, its structure is basically the same as embodiment 2, further:

[0057] In this embodiment, a material retaining ring 19 is connected to the end of the combustion channel 6 , and the inner wall of the material retaining ring 19 is fixed on the outer wall of the combustion channel 6 . During the rotation of the outer cylinder 1, the material channel 5 located at the upper end of the combustion channel 6, because the material is accumulated at the bottom, when the gas in the material channel 5 is sucked into the combustion channel 6, the material particles therein are easily Brought into the combustion channel 6, through the installation of the retaining ring 19, the material accumulated in the material channel 5 which is rotated to the upper part of the combustion channel 6 tail end can be blocked, preventing it from directly falling and being blown into the combustion channel 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com