A nitrogen-doped carbon sphere using lignin as raw material and its preparation method and application

A nitrogen-doped carbon and lignin technology, applied in the preparation/purification of carbon, can solve the problems that hinder the high-value utilization of lignin, cannot achieve high-efficiency utilization, and cannot show performance, so as to broaden the utilization of high added value , broad application prospects and market potential, the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

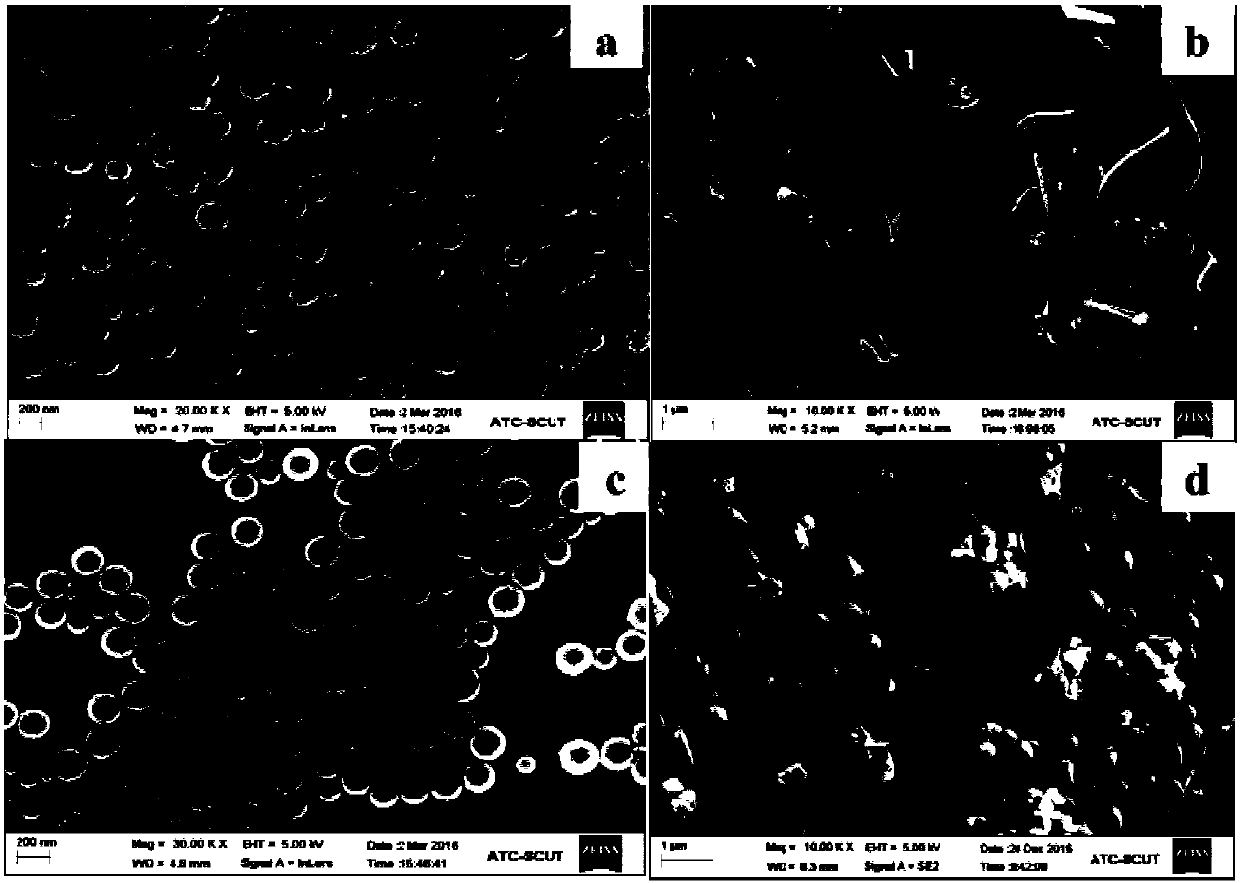

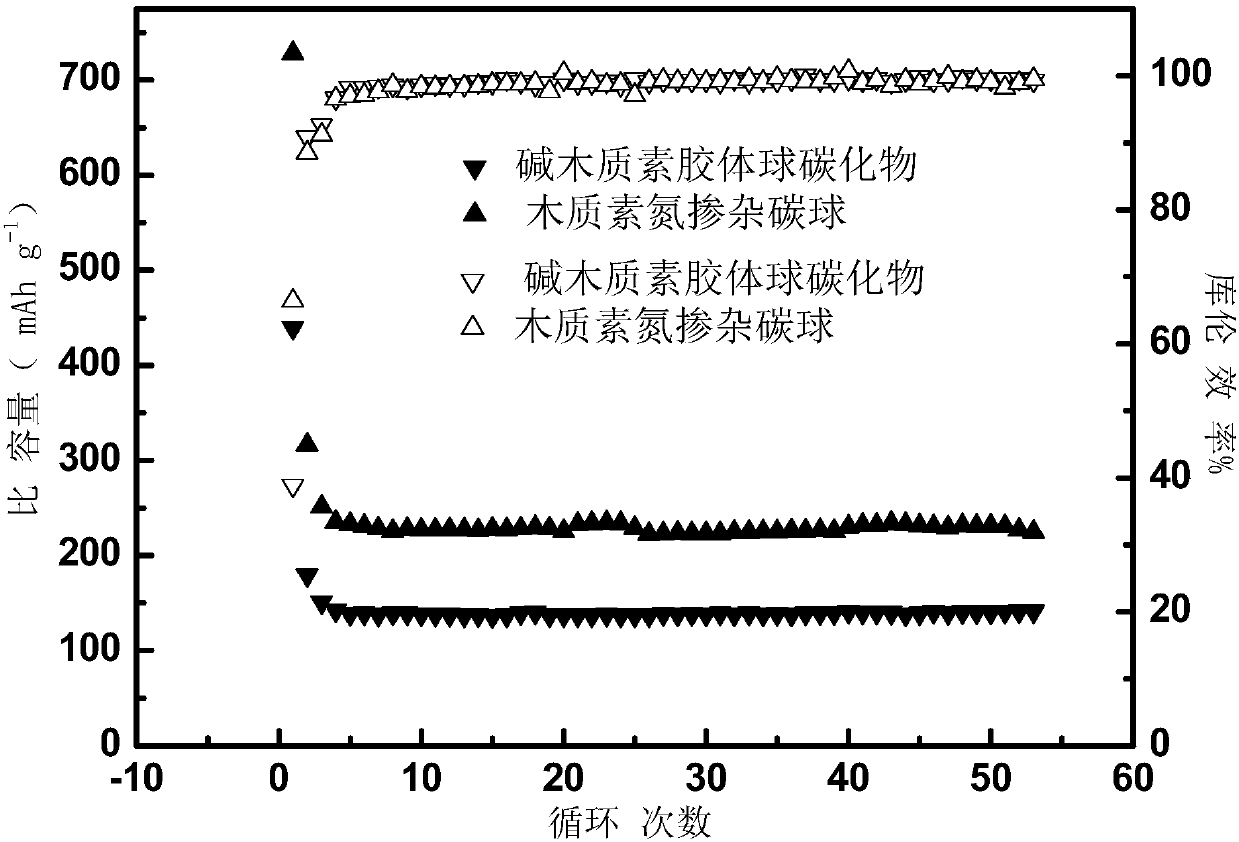

Embodiment 1

[0035] (1) Put 3.6g of alkaline pulping black liquor acid-analyzed alkali lignin in a 500mL flask, add 200mL of deionized water, adjust the pH to 12 with sodium hydroxide, heat in a water bath to 90°C, and add 0.64g of supernatant Oxidize hydrogen, seal and stir for 1 hour to obtain a demethoxylated lignin reaction solution.

[0036] (2) Put 1.45g of aniline in a 250mL flask, add 100mL of deionized water, add 2.5g of dilute sulfuric acid and adjust the pH to 2.5, react at 0-5°C for 20 minutes, add 5mL of g / mL sodium nitrite aqueous solution was reacted for 1 hour to obtain the corresponding diazonium salt reaction solution.

[0037] (3) Mix the products of step (1) and step (2), adjust the pH to 9 with sodium hydroxide, stir and react at 0°C for 1 hour, add dilute sulfuric acid until the pH is 1 to 3, precipitate, filter with suction, Dry to obtain lignin azo polymer.

[0038] (4) Put 2.5 g of the lignin azo polymer obtained in step (3) into a 1000 mL beaker, and add 500 mL ...

Embodiment 2

[0046] (1) Put 5.0g of alkaline pulping bamboo pulp black liquor acid-analyzed alkali lignin in a 1000mL flask, add 400mL of deionized water, adjust the pH to 12 with sodium hydroxide, heat in a water bath to 90°C, add 0.8g of supernatant Oxidize hydrogen, seal and stir for 2 hours to obtain a demethoxylated lignin reaction solution.

[0047] (2) Put 2.0g of aniline in a 250mL flask, add 150mL of deionized water, add 3.0g of dilute sulfuric acid and adjust the pH to 3, react at 0-5°C for 30 minutes, then add 7mL dropwise to a concentration of 0.25g / mL sodium nitrite aqueous solution for 2 hours to obtain the corresponding diazonium salt reaction solution.

[0048] (3) Mix the products of step (1) and step (2), adjust the pH to 9.5 with sodium hydroxide, stir and react at 0°C for 2 hours, add dilute sulfuric acid until the pH is 1 to 3, precipitate, filter with suction, Dry to obtain lignin azo polymer.

[0049] (4) Place 5.0 g of the lignin azo polymer obtained in step (3) ...

Embodiment 3

[0052] (1) Put 3.6g of alkaline pulping black liquor acid-analyzed alkali lignin in a 500mL flask, add 200mL of deionized water, adjust the pH to 12 with sodium hydroxide, heat in a water bath to 90°C, add 0.56g of supernatant Oxidize hydrogen, seal and stir for 1 hour to obtain a demethoxy lignin reaction solution.

[0053] (2) Put 2.64g of ethyl p-aminobenzoate in a 250mL flask, add 100mL of deionized water, add 2.5g of dilute sulfuric acid and adjust the pH to 2, react at 0-5°C for 20 minutes, drop by drop Add 5 mL of aqueous sodium nitrite solution with a concentration of 0.25 g / mL to react for 2 hours to obtain the corresponding diazonium salt reaction liquid.

[0054] (3) Mix the products of step (1) and step (2), adjust the pH to 10 with sodium hydroxide, stir and react at 0°C for 2 hours, add dilute sulfuric acid until the pH is 1 to 3, precipitate, filter with suction, Dry to obtain lignin azo polymer.

[0055] (4) Put 2.5 g of the lignin azo polymer obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com