Method for preparing tantalum oxynitride photocatalytic material by using waste tantalum capacitor

A photocatalytic material and tantalum capacitor technology, which is applied in the field of waste tantalum capacitor recycling, can solve the problems of high-purity tantalum oxide being expensive, the industrial application limitation of TaON photocatalytic material, etc., achieve broad application prospects and economic benefits, reduce tantalum Ore needs, the effect of high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

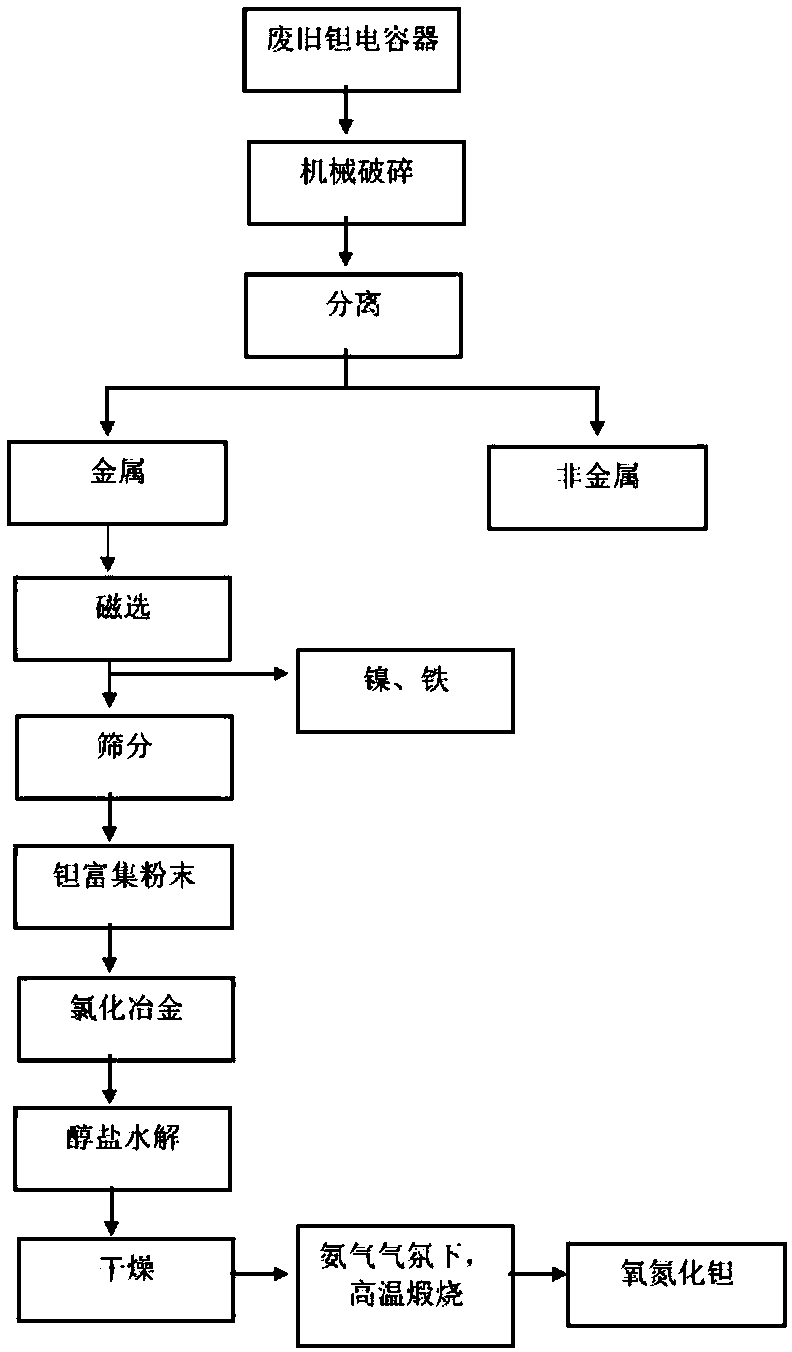

[0031] The method for preparing a visible light-responsive TaON photocatalytic material with waste tantalum capacitors described in the application of the present invention comprises the following steps:

[0032] 1. Mechanical crushing: Take 10g of resin-encapsulated waste tantalum capacitors with a tantalum content of 35.9%. The analysis results are as follows: Ta: 35.9%, Ag: 0.3%, Ni: 2.08%, Fe: 3.85%. Use a ball mill to crush waste tantalum capacitors to obtain materials with an average particle size of 0.5-0.01mm;

[0033] 2. Electrostatically sort the crushed materials to separate metal and non-metal;

[0034] 3. Magnetically separate metal materials to separate nickel and iron; then sieve to obtain Ta-enriched powder;

[0035] 4. Put the Ta-enriched powder in a tube furnace for chlorination to obtain TaCl 5 . Control the flow rate of argon gas to 50ml / min, the mass ratio of Ta-enriched powder to chloride salt is 1:1, the reaction temperature is 500°C, and the reaction...

Embodiment 2

[0048] The method for preparing a visible light-responsive TaON photocatalytic material with waste tantalum capacitors described in the application of the present invention comprises the following steps:

[0049] 1. Mechanical crushing: Take 10g of resin-encapsulated waste tantalum capacitors with a tantalum content of 35.9%. The analysis results are as follows: Ta: 35.9%, Ag: 0.3%, Ni: 2.08%, Fe: 3.85%. Use a hammer crusher to crush waste tantalum capacitors to obtain materials with an average particle size of 0.5-0.01mm;

[0050] 2. The crushed material is subjected to hydrocyclone separation to separate metal and non-metal;

[0051] 3. Magnetically separate metal materials to separate nickel and iron; then sieve to obtain Ta-enriched powder;

[0052] 4. Put the Ta-enriched powder in a tube furnace for chlorination to obtain TaCl 5 . Control the flow rate of argon gas to 80ml / min, the mass ratio of Ta-enriched powder to chloride salt is 1:2, the reaction temperature is 60...

Embodiment 3

[0058] The method for preparing a visible light-responsive TaON photocatalytic material with waste tantalum capacitors described in the application of the present invention comprises the following steps:

[0059] 1. Mechanical crushing: Take 10g of resin-encapsulated waste tantalum capacitors with a tantalum content of 35.9%. The analysis results are as follows: Ta: 35.9%, Ag: 0.3%, Ni: 2.08%, Fe: 3.85%. Use a hammer crusher to crush waste tantalum capacitors to obtain materials with an average particle size of 0.5-0.01mm;

[0060] 2. Electrostatically sort the crushed materials to separate metal and non-metal;

[0061] 3. Magnetically separate metal materials to separate nickel and iron; then sieve to obtain Ta-enriched powder;

[0062] 4. Put the Ta-enriched powder in a tube furnace for chlorination to obtain TaCl 5 . Control the flow rate of argon gas to 100ml / min, the mass ratio of Ta-enriched powder to chloride salt is 1:3, the reaction temperature is 650°C, and the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com