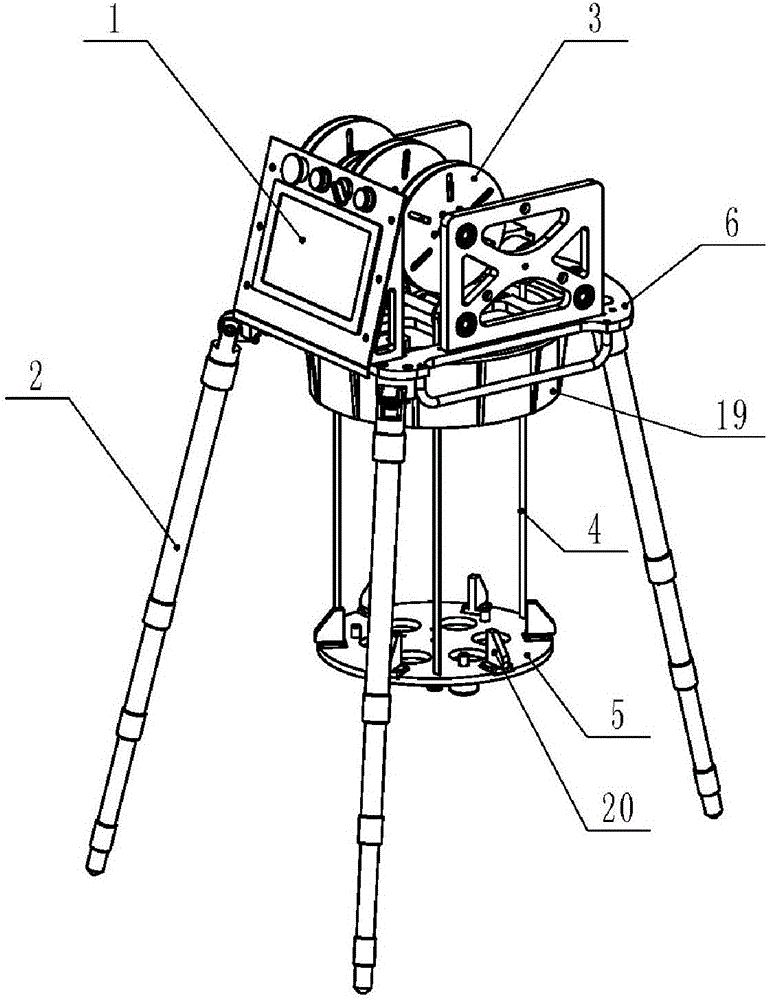

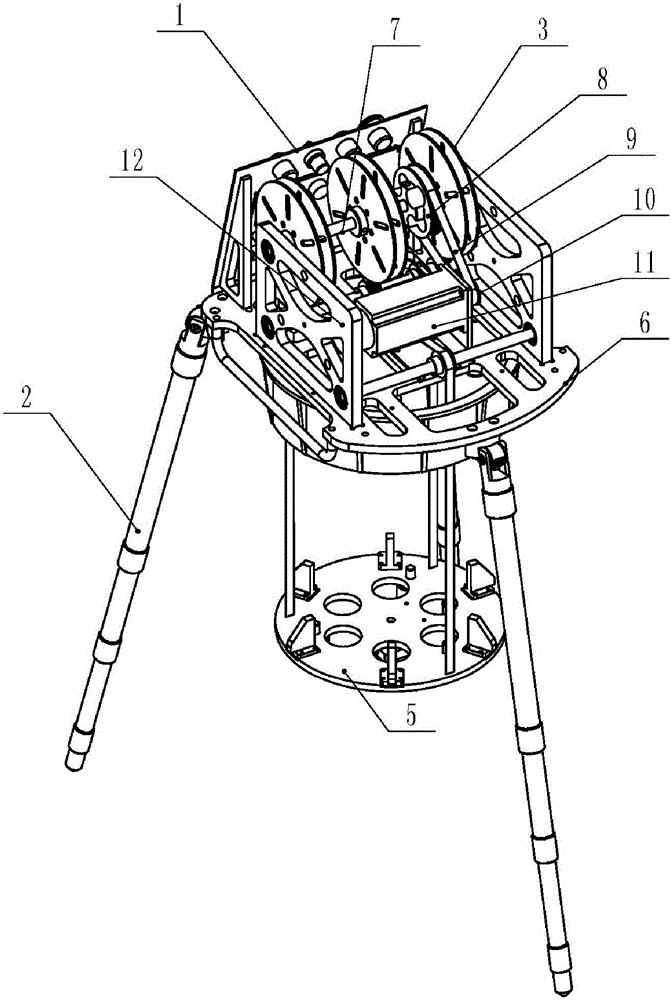

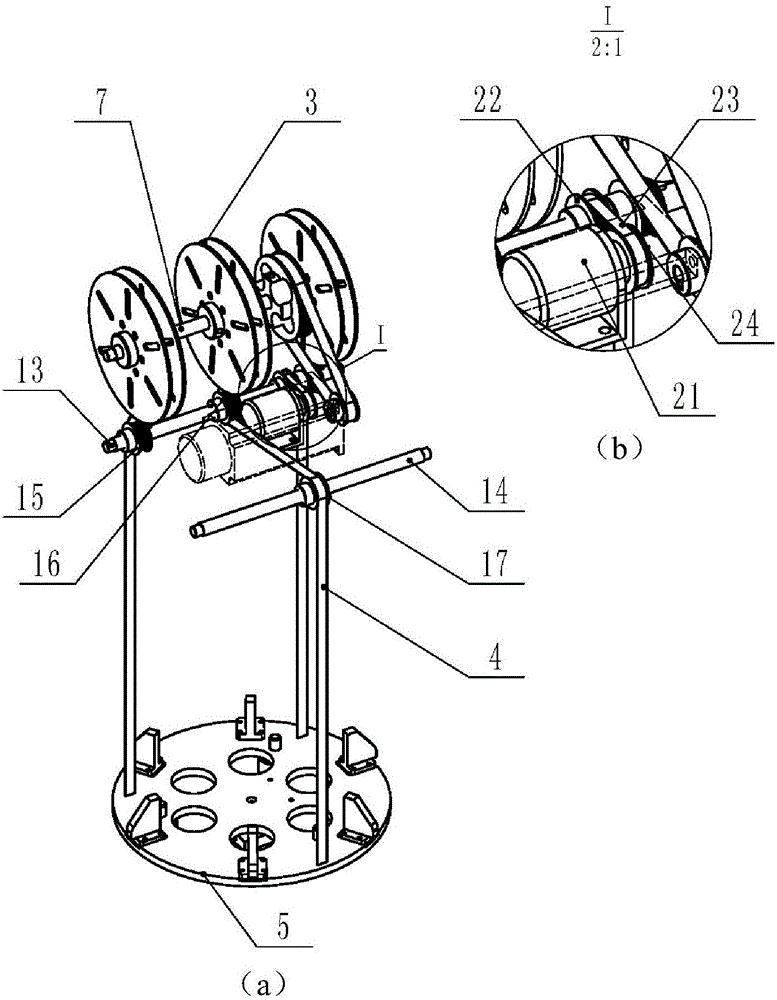

Three-point type lifting device for down-hole detection

A three-point, speed-measuring encoder technology, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of fluctuation of lifting speed, large size and weight of the device, difficult to control the position accuracy of lifting, etc., to reduce complexity and improve The effect of stability and high-precision position control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention provides a three-point lifting device for downhole detection, including a drive motor, a reel, a lifting timing belt, a timing pulley, a speed encoder, a detection base, a touch screen, and a detection base, and the drive motor drives the reel Rotate, the lifting timing belt is wound on the reel, the timing belt pulley is set under the reel, and is aligned with the lifting timing belt, the lifting timing belt is guided by the timing pulley in a three-point uniform distribution, and the lifting timing belt is connected to the detection base. The speed measuring encoder is used to measure the rotation speed of the synchronous pulley, and feed back the measurement signal to the control system. The rotation speed of the reel is controlled in real time by driving the motor, so that the detection base is lifted and lowered at a constant speed. All operations of the device are completed on the touch screen.

[0020] The present invention w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com