Hydraulic driving catenary maintenance operation vehicle

A technology of hydraulic transmission and hydraulic transmission box, which is applied in the field of hydraulic transmission catenary maintenance work vehicles, can solve the problems of large space and reduced space of the rear working platform, achieve high work efficiency, improve workplace conditions, and prevent failures low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

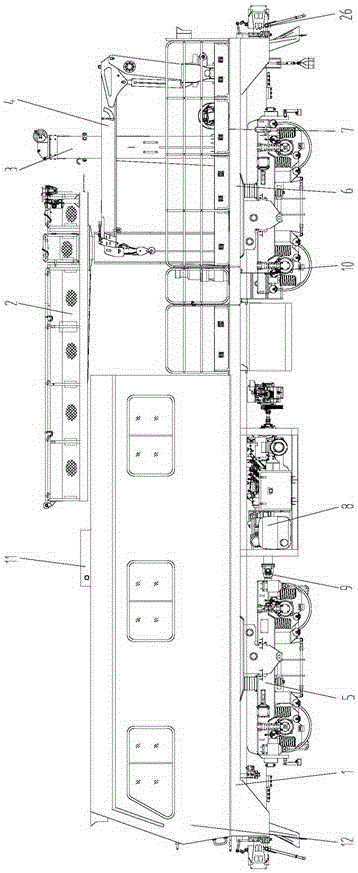

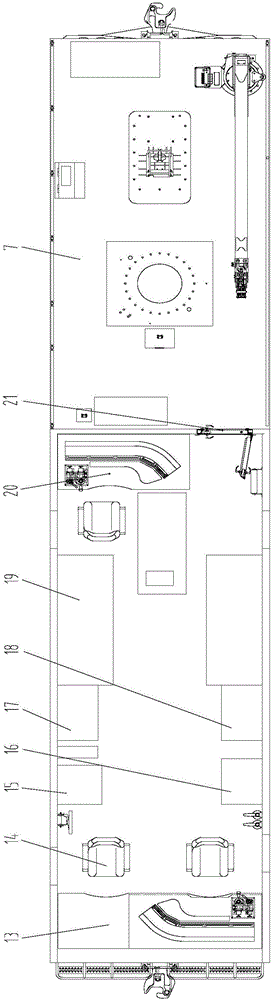

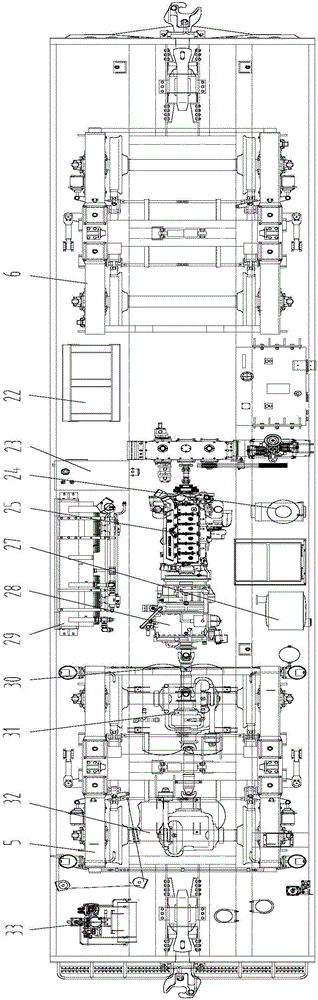

[0018] Attached below Figure 1-3 Embodiments of the present invention are described.

[0019] Hydraulic transmission catenary maintenance vehicle, such as figure 1 As shown, there is a vehicle frame 1, and the two ends of the vehicle frame 1 are provided with a traction device 26, and the traction device 26 adopts an upper acting type 13# coupler with an ST buffer. When the vehicle is impacted, the impact force can be reduced to Moderates and dampens shock and vibration between vehicles. The front end of the lower part of the vehicle frame 1 is provided with a power bogie 5, and the rear end of the lower part of the vehicle frame 1 is provided with a non-power bogie 6. The device is connected, and there is no need to tie up when the vehicle is hoisted or recovered. The middle part of the lower end surface of the vehicle frame 1 is provided with a power transmission integration device, the power transmission integration device includes an integrated bracket 10, and the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com