A carbon fiber thermal core floor based on a modified carbon fiber thermal core layer

A carbon fiber and modified carbon technology, applied in the directions of carbon fiber, fiber treatment, ultrasonic/sonic fiber treatment, etc., can solve the problem of little research on the heating performance of electric heating floors, and achieve good heat distribution uniformity, good dispersion, and heating rate. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Cut long fibers of polyacrylonitrile carbon fiber T-1000 to 3-5 cm, and then pour them into a high-speed grinder for cutting for 1 min to obtain short carbon fiber fibers to be modified.

[0030] (2) Place the short carbon fiber to be modified in the step (1) in a low-temperature plasma instrument, at 100 ° C and 1.5 × 10 5 Under Pa, under a nitrogen atmosphere, plasma treatment was performed with a power of 200W for 60s to obtain activated carbon fiber short fibers.

[0031] (3) In parts by weight, add 1 part of activated carbon fiber short fibers prepared in step (2) to 75 parts of 0.1 g / mol aniline-containing hydrochloric acid solution, stir slowly for 30 min, and add 2 parts of ammonium sulfate initiator , continue to stir and react at room temperature for 5 hours, take it out, rinse until the filtrate is neutral, and dry to obtain polyaniline-coated modified carbon fibers.

[0032] (4) Place the polyaniline-coated modified carbon fibers prepared in step (3) in...

Embodiment 2

[0035] (1) Cut long fibers of polyacrylonitrile carbon fiber M40 to 3-5 cm, and then pour them into a high-speed grinder for cutting for 3 minutes to obtain short carbon fiber fibers to be modified.

[0036] (2) Place the carbon fiber short fibers to be modified in step (1) in a low-temperature plasma instrument, at 140 ° C and 2 × 10 5 Under Pa, under a nitrogen atmosphere, plasma treatment was performed with a power of 300W for 90s to obtain activated carbon fiber short fibers.

[0037] (3) In parts by weight, add 1 part of activated carbon fiber short fibers prepared in step (2) to 90 parts of 0.2 g / mol aniline-containing hydrochloric acid solution, stir slowly for 30 min, and add 7 parts of ammonium sulfate initiator , continue to stir and react at room temperature for 10 h, take it out, rinse until the filtrate is neutral, and dry to obtain polyaniline-coated modified carbon fibers.

[0038] (4) The polyaniline-coated modified carbon fibers prepared in step (3) are place...

Embodiment 3

[0041] (1) Cut long fibers of polyacrylonitrile carbon fiber M60 to 3-5 cm, then pour into a high-speed grinder and cut for 2 minutes to obtain short carbon fiber fibers to be modified.

[0042] (2) Place the carbon fiber short fibers to be modified in step (1) in a low-temperature plasma instrument, at 120 ° C and 1.7 × 10 5 Under Pa, under a nitrogen atmosphere, plasma treatment was performed at a power of 250W for 80s to obtain activated carbon fiber short fibers.

[0043] (3) In parts by weight, add 1 part of activated carbon fiber short fibers prepared in step (2) into 80 parts of 0.15 g / mol aniline-containing hydrochloric acid solution, stir slowly for 30 min, and add 5 parts of ammonium sulfate initiator , continue to stir and react at room temperature for 8 hours, take it out, wash until the filtrate is neutral, and dry to obtain polyaniline-coated modified carbon fibers.

[0044] (4) The polyaniline-coated modified carbon fibers prepared in step (3) are placed in pap...

PUM

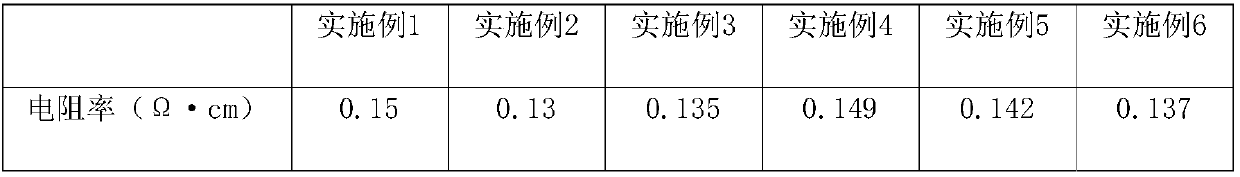

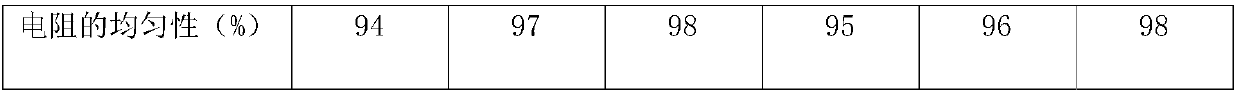

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com