Corrosion resistant fabric capable of improving guiding optical rotation

A corrosion-resistant and optically active technology, applied in the field of fabrics and textile fabrics, can solve the problems of low corrosion resistance, rough production and short service life, and achieve the effects of strong corrosion resistance, long service life and simple fabric structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

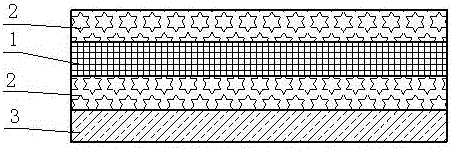

[0013] see figure 1 , a kind of anti-corrosion fabric that promotes optical rotation property, comprises base fabric layer, and the inner and outer sides of described base fabric layer are all provided with anti-corrosion layer, the inner side of described anti-corrosion layer is provided with fabric inner layer; adhesive bonding and fixing; the base fabric layer includes a first warp yarn and a first weft yarn, the first warp yarn is woven with ramie fiber, and the first weft yarn is woven with holy hemp fiber; the anti-corrosion layer is polychloride Vinyl coating; the fabric inner layer includes a second warp yarn and a second weft yarn, the second warp yarn is woven with sea-island fibers, and the second weft yarn is woven with flax fibers.

[0014] The back of the fabric inner layer is provided with a lining fabric layer, and the lining fabric layer is a kind of light-emitting fabric, including a light-transmitting unit, at least one light-emitting unit combined with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com