A magnetic field assisted micro-abrasive water jet machining method and its spraying device

A technology of abrasive water jet and injection device, which is applied in the direction of abrasive feeding device, abrasive, metal processing equipment, etc., can solve the problems of uneven supply of abrasive, uneven flow of abrasive, blockage of fine abrasive system, etc., and improve processing efficiency and processing quality, improving processing capacity and processing efficiency, and enhancing the effect of processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

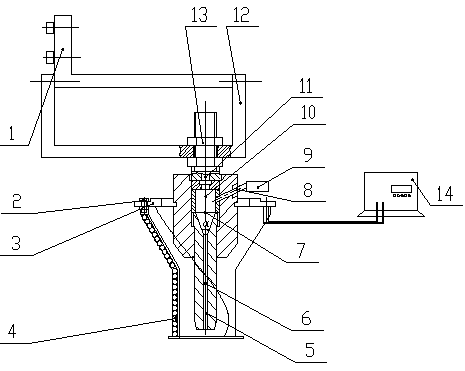

[0031] The invention provides a processing method of a magnetic field-assisted micro-abrasive water jet processing injection device, the process of which is operated according to the following steps:

[0032] The first step: the abrasive nozzle 5 moves to the top of the workpiece to be processed, and adjusts the appropriate target distance;

[0033] Step 2: Open the water valve to inject high-pressure water from the central pipeline 11 and spray it out through the high-pressure water nozzle 10;

[0034] The third step: open the abrasive supply device 9, the magnetic abrasive enters the mixing chamber 7 through the abrasive inlet 8 to mix with water, and finally sprays out through the abrasive nozzle 5 to form an abrasive jet; the function of the mixing chamber 7 is to promote the magnetic abrasive and water to mix fully;

[0035] Step 4: Turn on the DC power supply 14 switch, adjust the DC power supply 14 to obtain a suitable current, and make the magnetic field generating dev...

Embodiment 2

[0037] Embodiment 2: The processing method provided by the application embodiment 1 of the present invention is applied to a fine abrasive water jet processing injection device assisted by a magnetic field, and is characterized in that it includes a magnetic field generating device and a nozzle fixing device, and the magnetic field generating device is installed on the nozzle 5 above, the two are coaxial; the magnetic field generating device includes a metal ring 3 , a solenoid 4 , and a DC power supply 14 . The metal ring 3 is fixed on the outer edge of the nozzle through the slot, and the metal ring 3 is connected with the solenoid 4 through the bolt 2. When the DC power supply 14 supplies power, the solenoid generates a magnetic field of a certain strength. The nozzle fixing device includes an L-shaped connecting angle iron 1 , a fixing frame 12 and a hexagonal thin nut 13 . The L-shaped connecting angle iron 1 is connected with the fixed frame 12 by bolts, and the fixed fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com