Sand blasting derusting device for reinforcing steel bar

A sandblasting device and sandblasting rust removal technology are applied in the direction of abrasive feeding device, used abrasive processing device, abrasive jetting machine tool, etc., which can solve the problem that the lateral direction of the steel bar surface cannot be taken care of and rust removal is not possible. Sufficiency and other issues to achieve the effect of strengthening labor protection measures, avoiding damage, and reducing the length of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

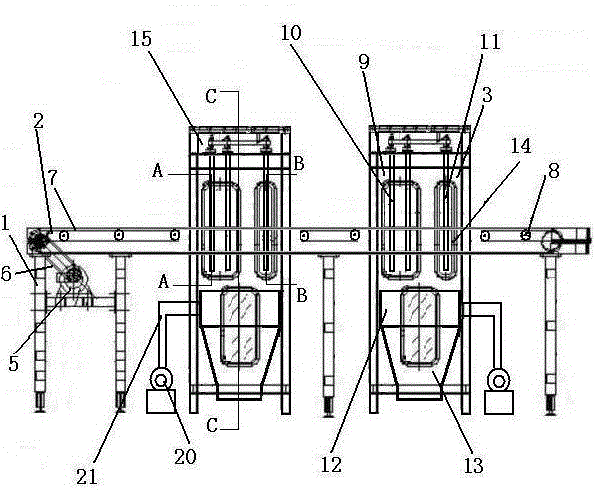

[0019] As shown in the figure, a sandblasting and derusting device for steel bars is installed, including a frame 1, a conveying device 2, a sandblasting device 3 and a sand suction device 4.

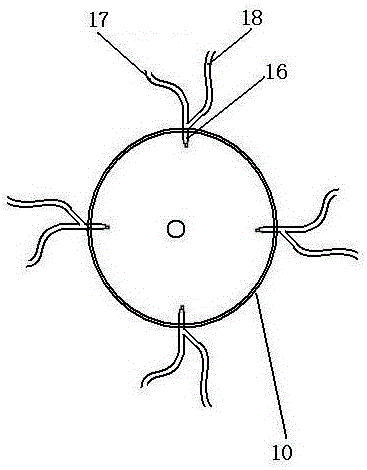

[0020] First install the frame 1 and the conveying device 2, the conveying device 2 includes a servo motor 5, a speed reducer, a sprocket mechanism 6, a transmission chain 7, a conveying roller 8 and a steel bar conveying trough 26; wherein the servo motor 5 and the decelerating The machine is connected with each other and installed in the lower part of the frame 1, the reducer is connected to the transmission chain 7 through the sprocket mechanism 6, and the transmission chain 7 is mounted on the side shaft of the conveying roller 8, so that the transmission chain 7 drives multiple groups of conveying rollers 8. The conveying roller 8 is installed on the frame 1 through the bearing, and two positioning rods are set in the middle of the conveying roller 8. The distance between the two po...

Embodiment 2

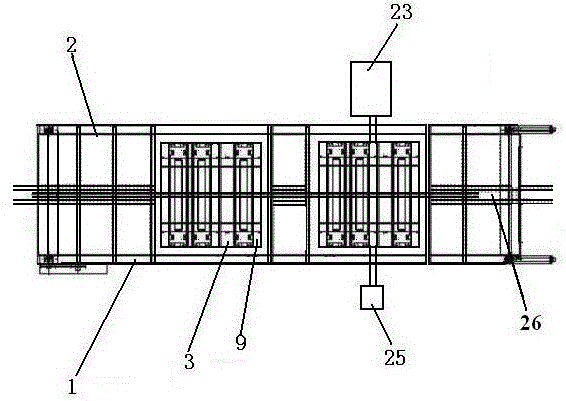

[0024] As shown in the figure, on the basis of Embodiment 1, two sandblasting devices 3 are installed sequentially on the frame, and the process length of each sandblasting device 3 is reduced, and a delivery support is set between the two sandblasting devices 3 Roller 8; the first sand blasting device adopts coarse steel grit, and the second sand blasting device adopts fine steel grit; in the second sand blasting device, the steel grit outlet 27 is directly connected to the sand cylinder 23 through the steel grit recovery pipe 22 .

[0025] In this way, it can avoid the excessively long vacancy of the conveying roller and ensure the driving force of continuous conveying of the steel bar; when in use, the first sandblasting device uses coarse steel sand for sandblasting, and the second sandblasting device uses fine steel sand for sandblasting; The outlet of the steel grit in the second sandblasting device is directly connected to the sand cylinder through the steel grit recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com