Multifunctional sheet metal stamping rack

A multi-functional, sheet metal technology, applied in the direction of metal processing equipment, forming tools, storage devices, etc., can solve the problems of troublesome assembly and debugging, large space occupation, and high overall production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

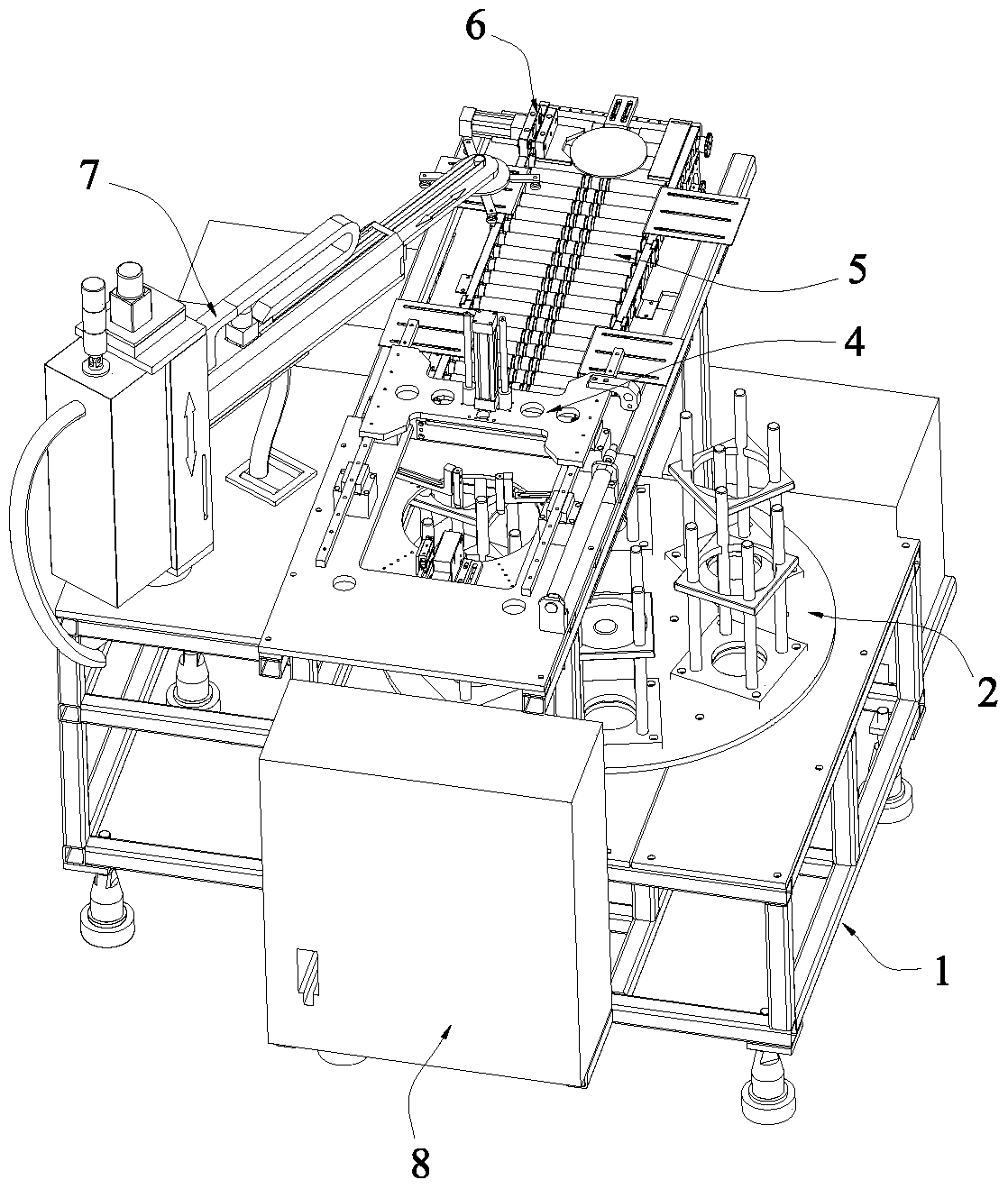

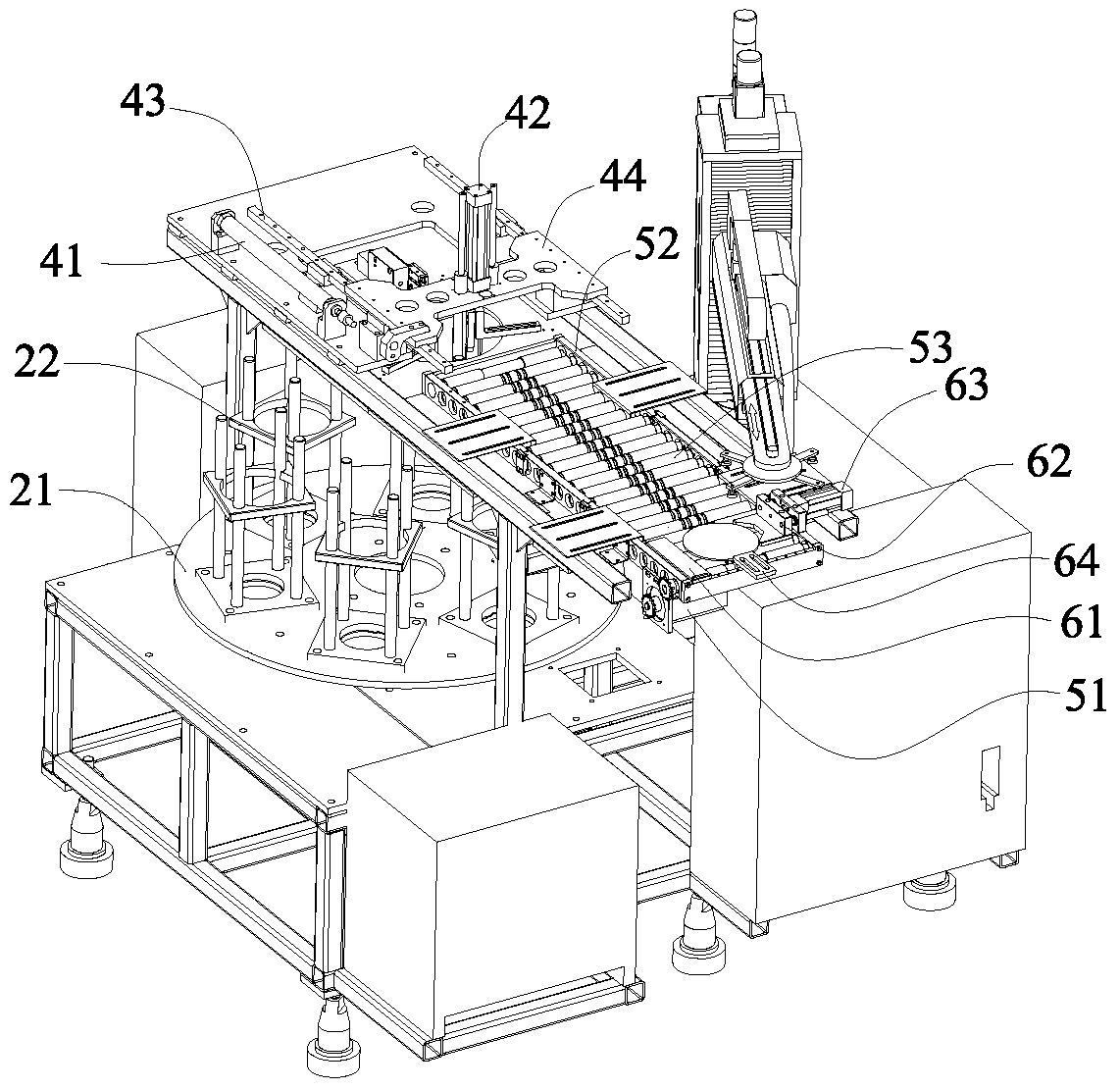

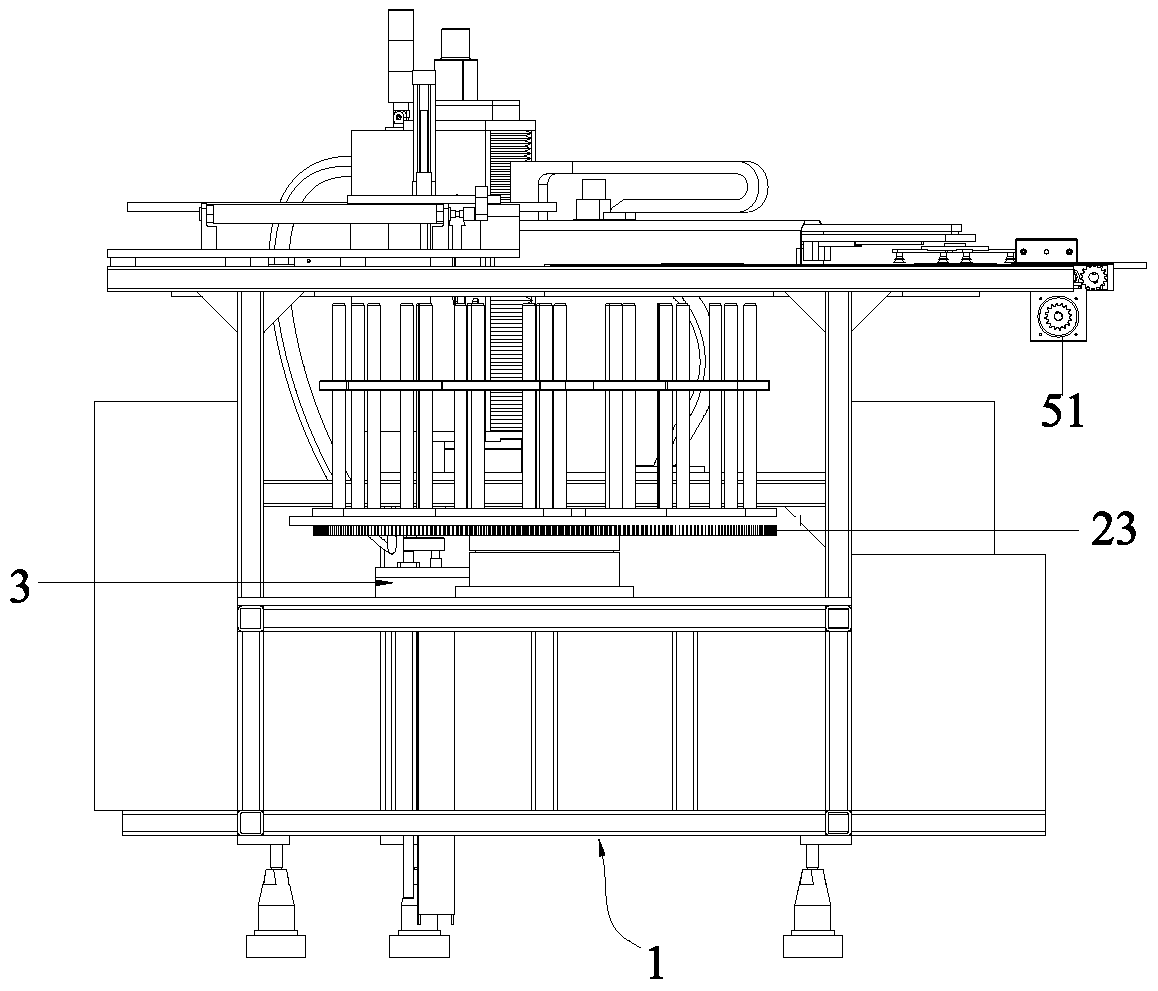

[0018] see figure 1 , figure 2 and image 3 , a multi-functional sheet metal stamping rack provided in this embodiment includes a frame 1, a multi-station rotating tray 2, a material jacking mechanism 3, a traverse retrieving mechanism 4, an oil rolling mechanism 5, and a sheet positioning Mechanism 6 and stamping manipulator 7, described multi-station rotary feeder 2 and rolling oil mechanism 5 are arranged on the frame 1, wherein the installation level of rolling oil mechanism 5 is higher than multi-station rotary feeder 2, described The ejecting mechanism 3 is arranged on the frame 1 corresponding to the lower position of the multi-station rotary tray 2, and can push the sheet material on the multi-station rotary tray 2 to a predetermined position. At the upper position of the multi-station rotary tray 2, the sheet material located at the predetermined position can be moved to the oil rolling mechanism 5, and the sheet material positioning mechanism 6 is arranged at one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com