Mobile whiteboard calibration target calibration device for material sorting equipment

A technology for calibrating device and whiteboard, applied in sorting, cleaning method using tools, cleaning method using gas flow, etc. Simple, easy to operate and highly automated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

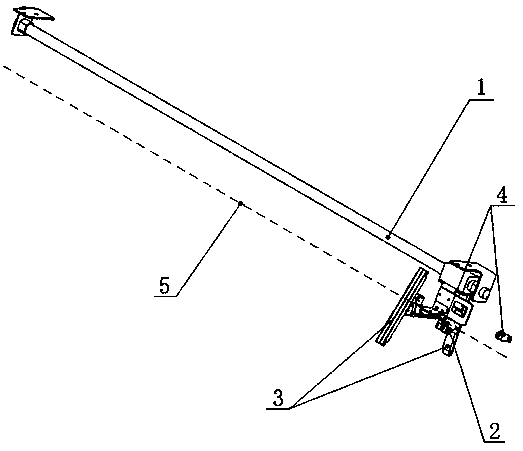

[0021] see Figure 1-2 , the invention discloses a mobile whiteboard calibration target calibration device for material sorting equipment. The slider on the cylinder, the slider is provided with a dust removal module and a whiteboard calibration target module 2, so that the slider can drive the dust removal module and the whiteboard calibration target module under the action of air pressure to stabilize Sliding, the machine viewing point 5 on the material sorting equipment is located on the moving path of the cleaning module.

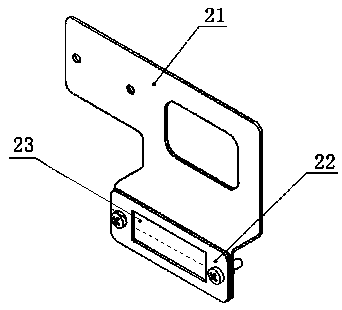

[0022] The whiteboard calibration target module includes a whiteboard calibration target 23, a whiteboard calibration target pressure plate 22 and a whiteboard calibration target mounting plate 21 for connecting the slider, the whiteboard calibration target is clamped between the whiteboard calibration target pressure plate and the Between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com