Integrated environment-friendly painting equipment

A kind of coating equipment and environmental protection technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of uneven coating on the surface of the material, pollution of the environment, leakage, etc., to improve the efficiency of dipping and avoid material waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

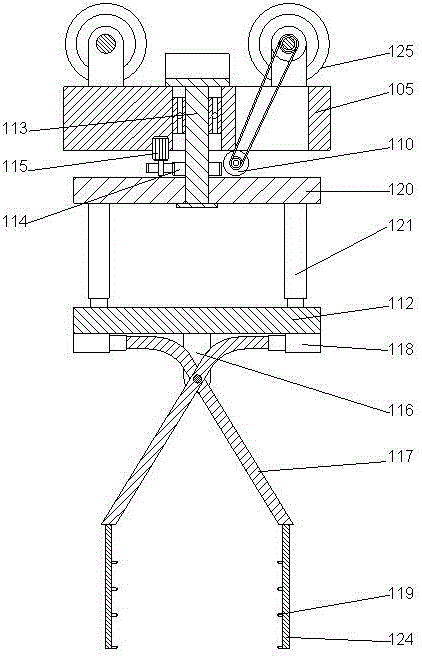

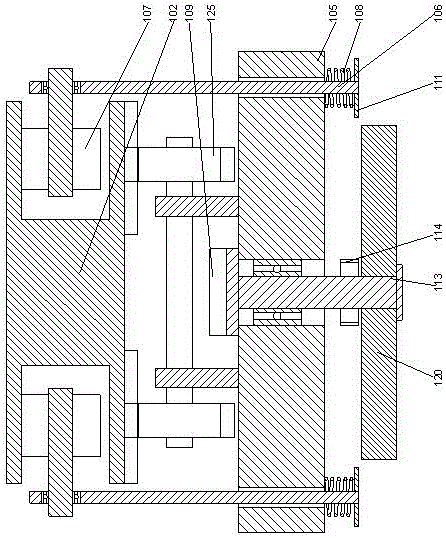

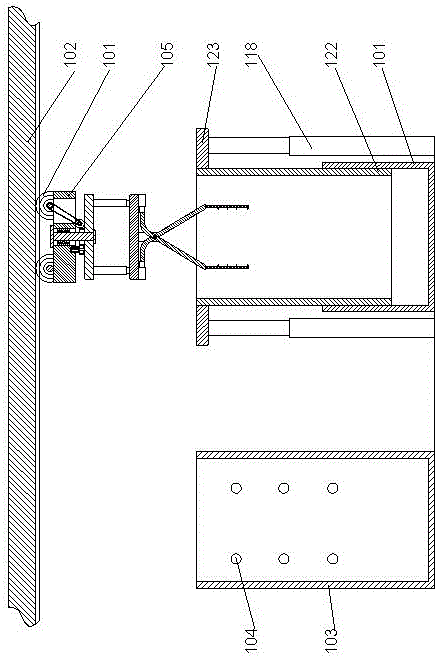

[0019] like figure 1 As shown, an integrated environmental protection painting equipment includes a hollow cylindrical paint box 101 and two moving rails 102 arranged above the paint box 101, and an air-drying box is arranged on one side of the paint box 101 103, at least two high-speed air nozzles 104 are arranged inside the air-drying box 103, the moving track 102 is I-shaped, and a moving platform 105 is set under the moving track 102, and the moving Two sets of gears 125 are arranged above the platform 105, and a driving motor 110 is arranged below the mobile platform 105, and the driving motor 110 is used to drive the rotation of the gear 125. Two positioning rods 106, rollers 107 are provided at the end of the positioning rods 106 away from the mobile platform 105, and the rollers 107 can be snapped into the grooves on both sides of the I-shaped moving track 102 And roll along the length direction of the groove, a through hole is provided on the mobile platform 105, the...

Embodiment 2

[0023] In this embodiment, in order to facilitate the lifting of the jaws, preferably, a lifting plate 120 is provided above the rotating platform 112, and the lower end of the rotating shaft 113 is fixedly connected to the lifting plate 120. The lower part of the lifting plate 120 is provided with a vertical lifting device 121, the lower end of the vertical lifting device 121 is connected with the rotating platform 112, and the vertical lifting device 121 is connected with the controller 109 through a line.

[0024] In this embodiment, further preferably, an extension rod 124 is provided at the end of the jaw 117 away from the rotating platform 112, and the positioning pins 119 are at least 2 symmetrically arranged on the extension rod 124. Group.

[0025] By arranging multiple sets of positioning pins, it is possible to clamp the plate material to be dipped, which helps to improve its stability.

Embodiment 3

[0027]In this embodiment, in order to dry the material with paint, preferably, a sleeve 122 is set inside the paint tank 101, and the sleeve 122 can be along the height direction of the paint tank 101 move. When needed, move the casing up so that the material with paint attached is placed inside the casing. At this time, when the material is turned to make the excess paint on the material fall, the paint will not be scattered outside the paint box, which can effectively avoid waste and pollution. .

[0028] In order to facilitate the automatic movement of the sleeve, in this embodiment, it is further preferred that lifting lugs 123 are provided outside the sleeve 122, and hydraulic cylinders 118 are respectively provided on both sides of the paint tank 101. The hydraulic cylinder 118 is arranged vertically, and the telescopic rod of the hydraulic cylinder 118 is connected with the lower end surface of the lifting ear 123 . Using the hydraulic cylinder structure, the controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com