Crushing device

A technology of crushing device and bottom plate, which is applied in the direction of grain processing, etc., can solve the problems of difficult fixing of large ores, easy splashing of small stones and hurting people, etc., and achieve the effect of preventing the movement of ore.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

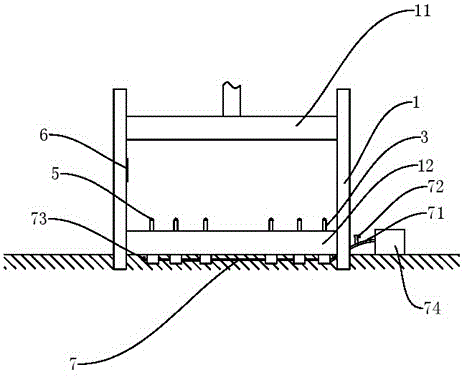

[0030] Basic as attached figure 1 Shown: Shredder, consisting of:

[0031] Frame, the frame is fixedly installed on the ground, the frame is surrounded by baffles, and the inner side of the baffle is provided with a sponge cushion;

[0032] Press plate, the frame is provided with a slide rail for the press plate to slide up and down, and a hydraulic press is fixed above the press plate, and the hydraulic press drives the press plate to rise or fall;

[0033] The bottom plate, the bottom plate is fixed on the ground, the bottom plate is fixedly connected with the frame, the bottom plate is located directly under the pressure plate, and the bottom plate is provided with connection holes;

[0034] Locating pin, the locating pin is located in the connection hole, the locating pin is slidingly connected with the bottom plate, the upper part of the locating pin is provided with a spherical crown, and the crown is wrapped with a rubber layer;

[0035] Cylinder, the cylinder is buri...

Embodiment 2

[0040] Compared with Example 1, the only difference is that there is a powder leakage hole on the bottom plate, and the powder leakage hole and the connecting hole are arranged at intervals, and a collection bin is arranged under the powder leakage hole, and the collection bin is buried under the bottom plate, and the inner wall of the collection bin A rubber layer is bonded, a screw is nailed on the rubber layer, a hair ball is tied with a rope on the screw, and the hair ball can swing freely on the rubber layer. During the initial crushing process, the frame and the ground will vibrate slightly, which will cause the hair ball to swing. During the swing process, the rubber layer will be charged, so that the rubber layer can absorb the powder falling from the powder leakage hole. of fine dust.

Embodiment 3

[0042] Compared with Embodiment 1, the only difference is that the infrared sensor is replaced by a pressure sensor. The pressure sensor is located on the movement track of the pressing plate, and the pressure sensor is fixed on the frame. The pressure sensor takes its own pressure as the basis for judgment, has a simple structure, is convenient to install, and is accurate in judgment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com