Method for preparing high-strength and high-toughness poly-ion hydrogel support through 3D printing

A 3D printing, high-toughness polymer technology, applied in medical science, prosthesis, additive processing, etc., can solve problems such as insufficient breaking strength, loss of toughness, and failure to reach high-strength hydrogels, and achieves simple preparation methods, Effect of improving mechanical strength and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

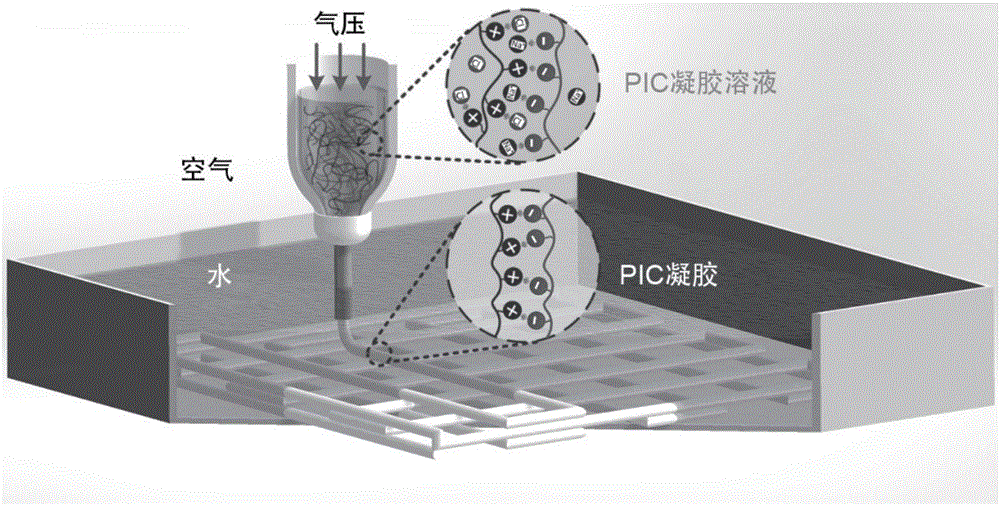

Method used

Image

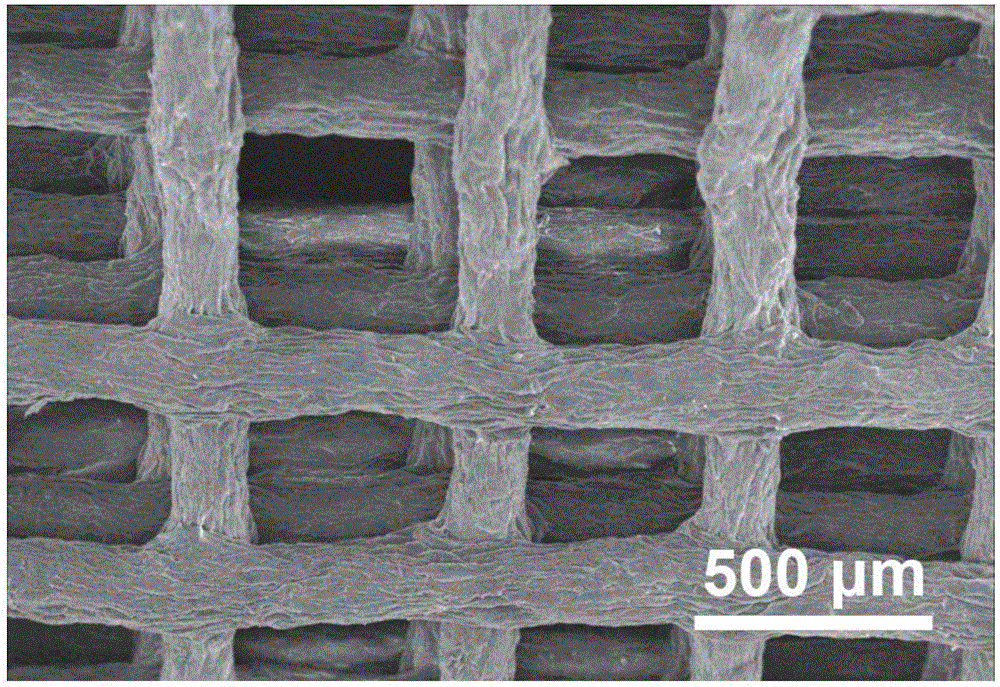

Examples

Embodiment 1

[0050] (1) N, N, N-trimethyl-3-(2-methacryloylamino)-1-propylammonium chloride (MPTC) and sodium p-styrenesulfonate ( NaSS) solution placed at a wavelength of 365nm and a power of 7.5mW / cm 2 Irradiate under the ultraviolet lamp for 8 hours to obtain the solution of two kinds of polymers. After purification by ethanol precipitation, oven drying and grinding, poly-N,N,N-trimethyl-3-(2-methacrylamino) - 1-propylammonium chloride (PMPTC) and polysodium p-styrene sulfonate (PNaSS) powder;

[0051] N, N, N-trimethyl-3-(2-methacrylamino)-1-propyl ammonium chloride solution concentration is 1mol / L, p-styrene sodium sulfonate solution concentration is 1mol / L, light The initiator is α-pentanonedioic acid, and the addition amount of the photoinitiator is 0.05mol% (relative to the concentration of the monomer);

[0052] (2) Poly-N,N,N-trimethyl-3-(2-methacrylamino)-1-propyl ammonium chloride is calculated as ammonium ion, polysodium p-styrenesulfonate is calculated as sulfonate ion Acc...

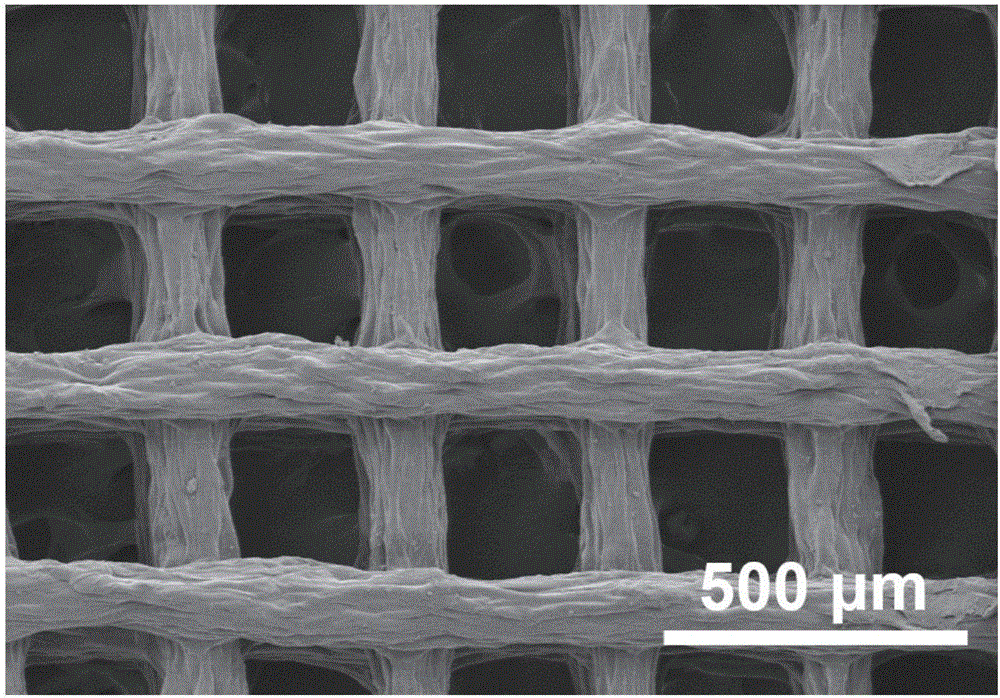

Embodiment 2

[0062] (1) N, N, N-trimethyl-3-(2-methacryloylamino)-1-propylammonium chloride (MPTC) and sodium p-styrenesulfonate ( NaSS) solution placed at a wavelength of 365nm and a power of 7.5mW / cm 2 Irradiate under the ultraviolet lamp for 8 hours to obtain the solution of two kinds of polymers. After purification by ethanol precipitation, oven drying and grinding, poly-N,N,N-trimethyl-3-(2-methacrylamino) - 1-propylammonium chloride (PMPTC) and polysodium p-styrene sulfonate (PNaSS) powder;

[0063] N, N, N-trimethyl-3-(2-methacrylamino)-1-propyl ammonium chloride solution concentration is 1mol / L, p-styrene sodium sulfonate solution concentration is 1mol / L, light The initiator is α-pentanonedioic acid, and the addition amount of the photoinitiator is 0.05mol%;

[0064] (2) Poly-N,N,N-trimethyl-3-(2-methacrylamino)-1-propyl ammonium chloride is calculated as ammonium ion, polysodium p-styrenesulfonate is calculated as sulfonate ion According to the calculation, poly-N,N,N-trimethyl...

Embodiment 3

[0073] (1) N, N, N-trimethyl-3-(2-methacryloylamino)-1-propylammonium chloride (MPTC) and sodium p-styrenesulfonate ( NaSS) solution placed at a wavelength of 365nm and a power of 7.5mW / cm 2 Irradiate under the ultraviolet lamp for 8 hours to obtain the solution of two kinds of polymers. After purification by ethanol precipitation, oven drying and grinding, poly-N,N,N-trimethyl-3-(2-methacrylamino) - 1-propylammonium chloride (PMPTC) and polysodium p-styrene sulfonate (PNaSS) powder;

[0074] N, N, N-trimethyl-3-(2-methacrylamino)-1-propyl ammonium chloride solution concentration is 1mol / L, p-styrene sodium sulfonate solution concentration is 1mol / L, light The initiator is α-pentanonedioic acid, and the addition amount of the photoinitiator is 0.05mol%;

[0075] (2) Poly-N,N,N-trimethyl-3-(2-methacrylamino)-1-propyl ammonium chloride is calculated as ammonium ion, polysodium p-styrenesulfonate is calculated as sulfonate ion According to the calculation, poly-N,N,N-trimethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com