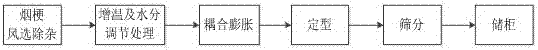

A method for improving the uniformity and quality of microwave expansion of tobacco stems

A technology of microwave expansion and uniformity, applied in tobacco, tobacco treatment, application, etc., can solve the problems of reducing the microwave expansion rate of tobacco stems, high manufacturing precision requirements, and difficult application, so as to achieve stable moisture and heat conduction, and reduce scorch The effect of improving the richness of miscellaneous smell and aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

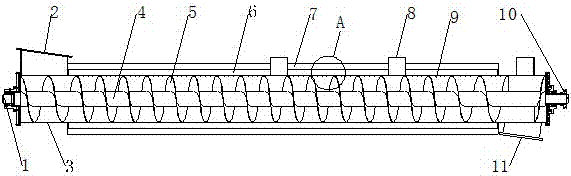

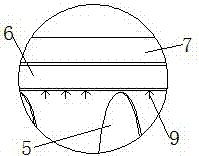

[0043] The raw tobacco stems are air-selected to remove impurities, such as hemp rope and dust, and then enter the screw conveying device through the feed port 2, and then are evenly mixed and transported forward under the rotation of the screw shaft 3 and the screw blade 4; Steam enters the screw shaft 3 from the steam inlet 9 of the screw shaft and is slowly discharged from the steam outlet 1 of the screw shaft, and the steam jacket 6 is also filled with steam, so that the tobacco stems can be continuously and evenly distributed from the steam jacket 6 and the steam jacket 6 during the transportation process. The screw shaft 3 absorbs heat; at the same time, the steam atomizing nozzle 8 on the upper part of the device continuously sprays steam to the tobacco stems during the transportation of the tobacco stems, so that the moisture and heat conduction between the tobacco stems can be relatively stable. The tobacco stems after moisture adjustment are output from the discharge ...

Embodiment 2

[0045] The raw tobacco stems are air-selected to remove impurities, such as hemp rope and dust, and then enter the screw conveying device through the feed port 2, and then are evenly mixed and transported forward under the rotation of the screw shaft 3 and the screw blade 4; Steam enters the screw shaft 3 from the steam inlet 9 of the screw shaft and is slowly discharged from the steam outlet 1 of the screw shaft, and the steam jacket 6 is also filled with steam, so that the tobacco stems can be continuously and evenly distributed from the steam jacket 6 and the steam jacket 6 during the transportation process. The screw shaft 3 absorbs heat; at the same time, the steam atomizing nozzle 8 on the upper part of the device continuously sprays steam to the tobacco stems during the transportation of the tobacco stems, so that the moisture and heat conduction between the tobacco stems can be relatively stable. The tobacco stems after moisture adjustment are output from the outlet 10,...

Embodiment 3

[0047] The raw tobacco stems are air-selected to remove impurities, and light impurities such as hemp ropes are removed. After entering the screw conveying device through the feed port 2, they are evenly mixed and transported forward under the rotation of the screw shaft 3 and the screw blade 4; The steam inlet 9 of the screw shaft enters the screw shaft 3 and is slowly discharged from the steam outlet 1 of the screw shaft, and the steam jacket 6 is also filled with steam, so that the tobacco stems can be continuously and evenly distributed from the steam jacket 6 and the screw shaft during transportation. 3 Absorption of heat; at the same time, the steam atomizing nozzle 8 on the upper part of the device continuously sprays steam to the tobacco stems during the transportation of the tobacco stems, so that the moisture and heat conduction between the tobacco stems can be relatively stable. The treated tobacco stems are output from the outlet 10, the average temperature of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com