Patch

A patch and adhesive technology, applied in the direction of adhesives, adhesive types, polyether adhesives, etc., to achieve the effect of high re-adhesive force and excellent repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The conditions of Example 1 are as follows.

[0054] The mixing amount of (A) component and (C) component (when the total amount of the composition is 100g)

[0055] (A) 4.8 g of partially neutralized polyacrylic acid (neutralization degree: 40 mol%)

[0056] (C) tartaric acid (valence: 2) 1g

[0057] (1) Acrylate unit and acrylic acid unit of component (A)

[0058] If the total of the acrylate units and the acrylic acid units in 4.8 g of the above partially neutralized polyacrylic acid is X, and the number of acrylate units is Y, then the following formula holds:

[0059] 72X+23Y=4.8

[0060] Y=0.4X

[0061] Here, solve the above formula, find X and Y, and get

[0062] X=0.0591···(I)

[0063] Y=0.0236···(II)

[0064] (2) Carboxyl group of component (C)

[0065] According to the above conditions

[0066] 1×2 / 150=0.0133···(III)

[0067] (3) Calculation of value

[0068] According to the above (I) to (III),

[0069] [(II)-(III)] / (I)

[0070] =(0.0236-0.0133) / ...

Embodiment 1~16、 comparative example 1~6

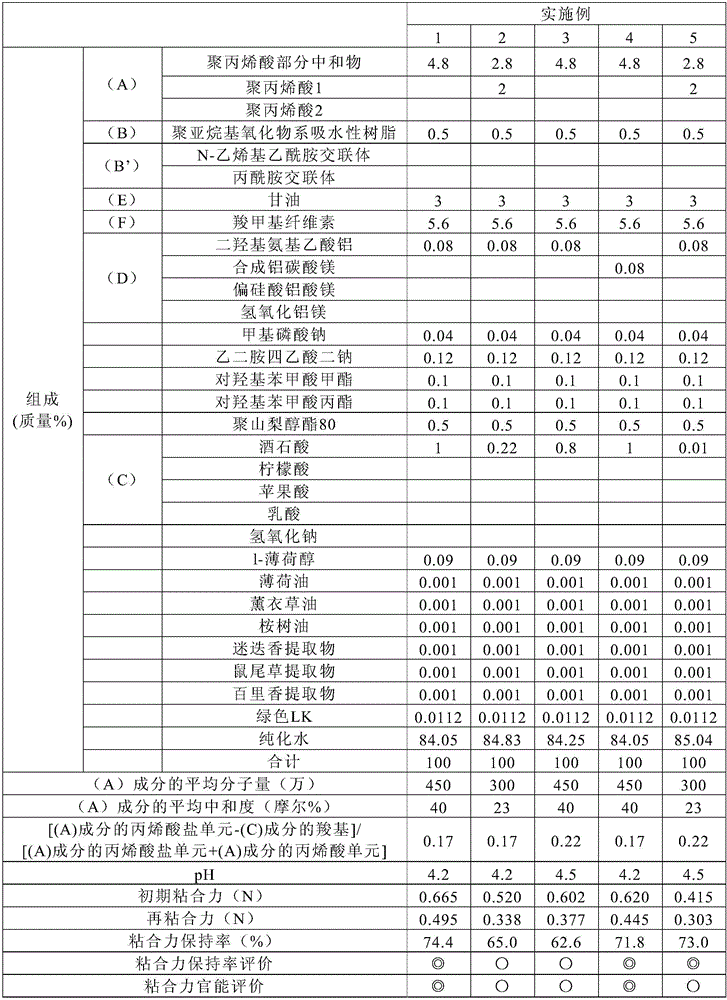

[0096] According to the proportions shown in Tables 1 to 4, each component was mixed using a Henschel mixer (manufactured by Nippon Coke Industry Co., Ltd. (Nippon Coke Industry Co., Ltd., model: FM 20C / I) to obtain an adhesive composition Then, use a spreading machine (manufactured by Ikeda Machinery Industry Co., Ltd., model: TC-340) on a non-woven fabric with a width of 30 cm (polyester non-woven fabric manufactured by Kurabo Textile Processing Co., Ltd.: weight per unit area of non-woven fabric 90g / m 2 ), spread the adhesive composition obtained above uniformly to form an adhesive layer, and further cover the adhesive layer with a plastic film (surface layer, polyester film made by Unitiki Co., Ltd.: thickness 25 μm). The surface of the agent layer is obtained as a patch. Relative to the support body 140cm 2 , the spreading amount of the adhesive composition was 28.5 g. In addition, in order to prevent drying, put the obtained patch into the inner bag (paper 64g / m 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com