Mid-infrared gas cascaded Raman laser with all-fiber structure

A Raman laser and Raman laser technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of high pumping threshold and limited effective distance, so as to improve pumping intensity and suppress competition Effect of Raman laser on improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

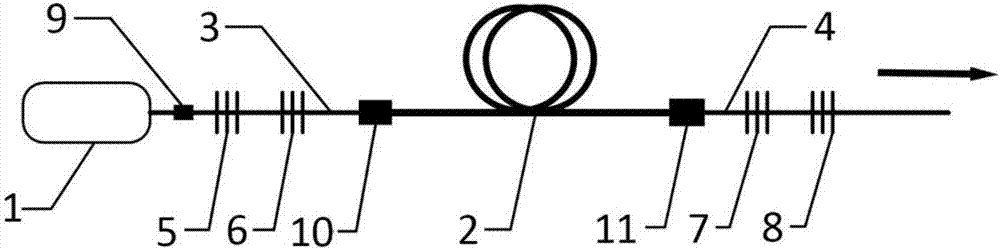

[0025] Such as figure 1 As shown, the all-fiber structure mid-infrared gas cascade Raman laser of this embodiment includes a near-infrared tunable fiber laser pump source 1, an anti-resonant hollow-core fiber 2, an input solid-core fiber 3, and an output solid-core fiber 4. The two ends of the input solid-core fiber 3 are respectively fused to the output pigtail of the near-infrared tunable fiber laser pump source 1 and one end of the anti-resonant hollow-core fiber 2, wherein the output pigtail of the near-infrared tunable fiber laser pump source 1 The first fusion splice point 9 is low-loss fusion spliced with the input solid-core fiber 3, one end of the anti-resonance hollow-core fiber 2 is low-loss spliced with the input solid-core fiber 3 through the second fusion splice point 10, and the other end of the anti-resonance hollow-core fiber 2 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com