Photoretroreflective counter electrode of a solar cell and preparation method thereof

A solar cell and retro-reflective technology, which is applied in the field of solar cells, can solve the problems of impossibly high reflection efficiency, large light loss of metal reflective film, and change of optical path, so as to improve photoelectric conversion efficiency, small light loss, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

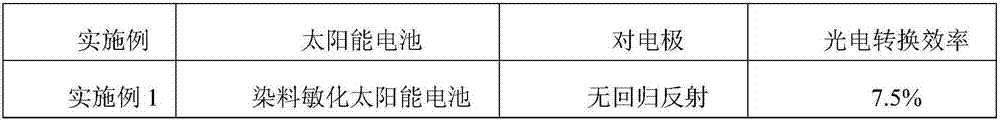

Embodiment 1

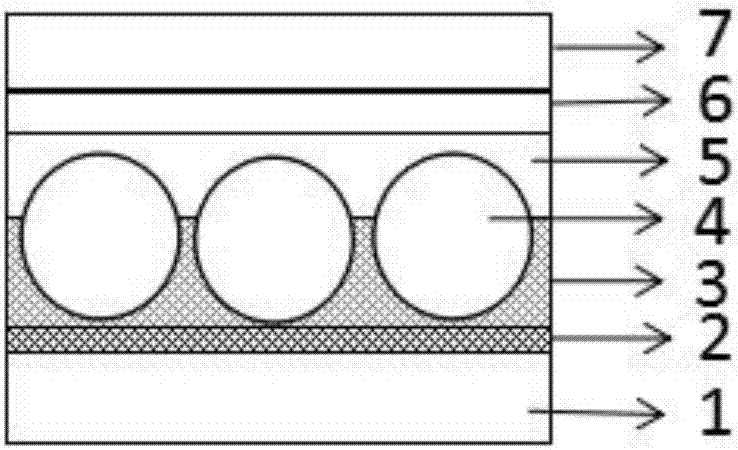

[0045] Such as figure 1 As shown, the light retroreflective counter electrode of the dye-sensitized solar cell in this embodiment includes a substrate 1, a first reflective layer 2, a second reflective layer 3, and a transparent resin layer sequentially arranged on the substrate 1 from bottom to top. 5. Adhesive layer 6 and solar cell counter electrode layer 7, wherein the thickness of the second reflective layer 3 is greater than the thickness of the first reflective layer 2, and the second reflective layer 3 is evenly distributed with glass beads 4, the glass The lower part of the microbead 4 is embedded in the second reflective layer 3 , and the upper part is embedded in the transparent resin layer 5 .

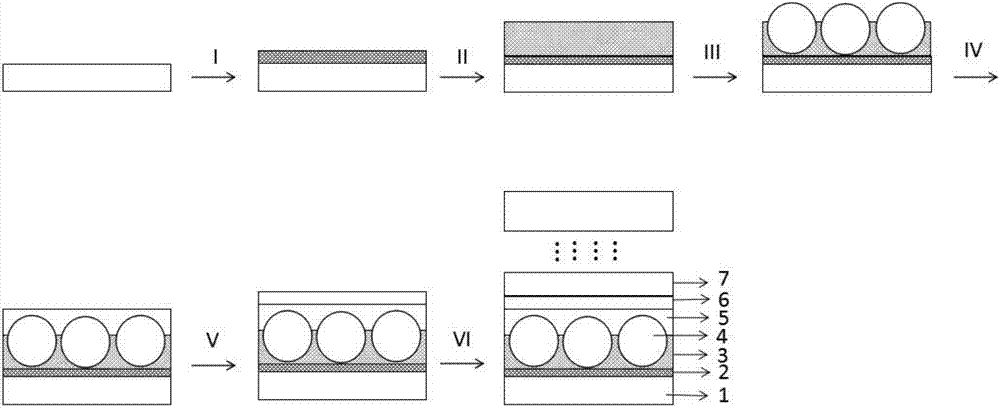

[0046] Such as figure 2 As shown, the method for preparing the photoretroreflective counter electrode of the dye-sensitized solar cell in this embodiment includes the following steps:

[0047] 1) Substrate 1 cleaning

[0048] Take a stainless steel substrate 1 with a le...

Embodiment 2

[0064] Fabrication of light retroreflective counter electrode for dye-sensitized solar cells:

[0065] 1) Substrate 1 cleaning

[0066] Take a glass substrate 1 with a length of 2 cm and a width of 1.5 cm, and clean the surface of the substrate 1 with cleaning agent and water, and dry it.

[0067] 2) Coating the first reflective layer 2

[0068] Using screen printing technology, the high-temperature silver reflective layer paste is evenly coated on the surface of a clean glass substrate 1 to form the first reflective layer 2. The mesh number of the screen is 250 mesh, and the thickness of the first reflective layer 2 is 2.5 microns. Heat at 500°C for 60 minutes to make it fully cured.

[0069] 3) Coating the second reflective layer 3

[0070] Using screen printing technology, the high-temperature silver reflective layer paste is evenly coated on the first reflective layer 2 to form the second reflective layer 3. The screen mesh is 150 mesh, and the printing is repeated 5 t...

Embodiment 3

[0082] Fabrication of light retroreflective counter electrode for dye-sensitized solar cells:

[0083] 1) Substrate 1 cleaning

[0084] Take a plastic substrate 1 with a length of 2 cm and a width of 1.5 cm, and clean the surface of the substrate 1 with cleaning agent and water, and dry it.

[0085] 2) Coating the first reflective layer 2

[0086] Using screen printing technology, the low-temperature silver reflective layer paste is evenly coated on the surface of a clean glass substrate 1 to form the first reflective layer 2. The mesh number of the screen screen is 250 mesh, and the thickness of the first reflective layer 2 is 3 microns. Heat at 150°C for 30 minutes to make it fully cured.

[0087] 3) Coating the second reflective layer 3

[0088] Using screen printing technology, the low-temperature silver reflective layer paste is evenly coated on the first reflective layer 2 to form the second reflective layer 3. The screen mesh is 100 mesh, and the printing is repeate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com