Magnetic shielding structure applied to ultrahigh voltage autotransformer clamp

An autotransformer and magnetic shielding technology, which is applied in transformers, fixed transformers, magnetic field/electric field shielding, etc., can solve the problems of reducing loss, local overheating, hysteresis loss, eddy current loss, etc., to reduce additional loss, reduce accident rate, Effect of improving electrical conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

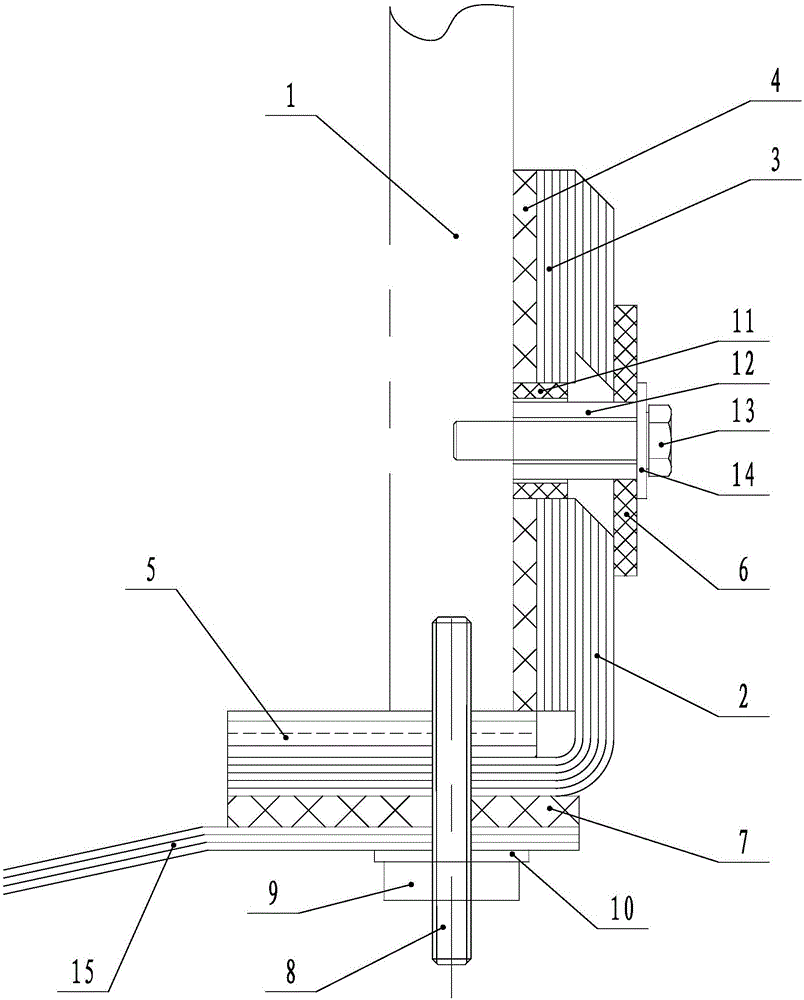

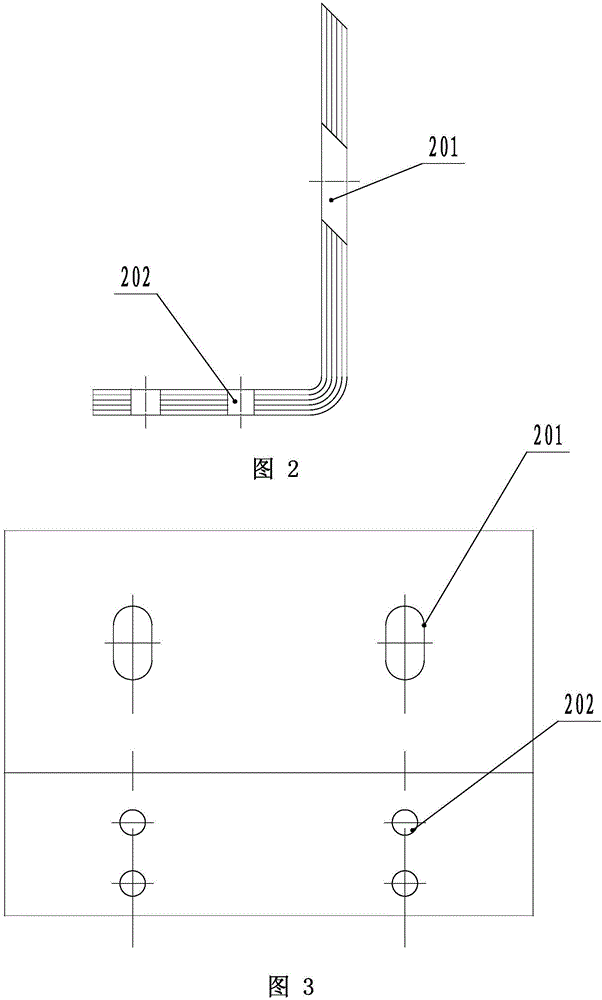

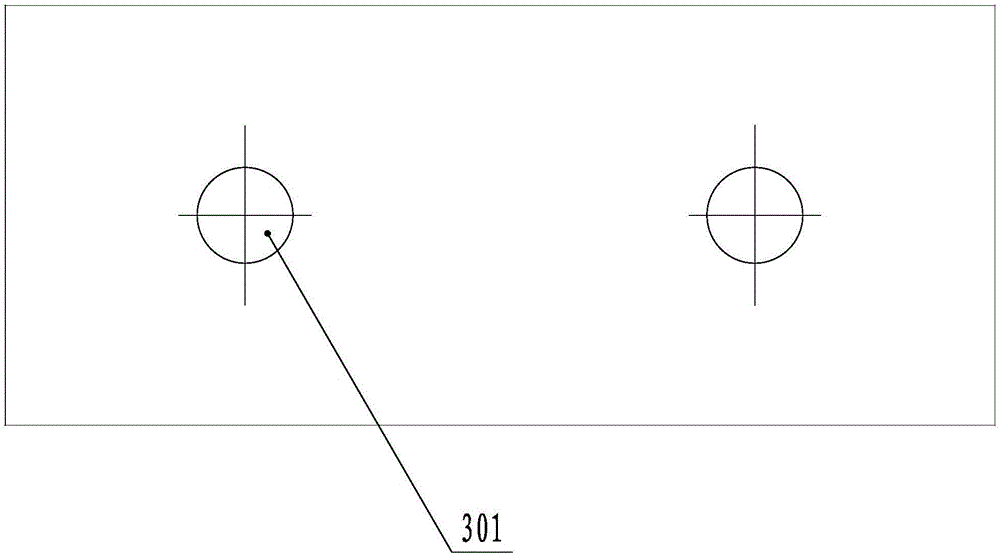

[0021] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] Such as Figure 1-4 As shown, the present invention includes a bent magnetic shield 2, a first inner insulating backing plate 4, a fastener connecting the bent magnetic shielding 2 and the first inner insulating backing plate 4 to the clip 1, and the bent magnetic shield 2. The cross-section is "L", and the bending part has a circular arc transition; the bending magnetic shielding part 2 is arranged at the outer end of the clamping part 1. By installing an "L"-shaped bent magnetic shield 2 on the outer end of the clip 1 with a relatively high leakage flux density, the leakage flux is reduced from entering the non-magnetic clip 1, and the leakage flux can be effectively reduced additional loss.

[0023] In order to better reduce the leakage magnetic flux into the non-magnetic clip 1, it also includes a direct magnetic shield ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com