A cavernous double-layer containment vessel for an underground nuclear power plant

A double-layer containment and containment technology, applied in the field of nuclear power, can solve the problems of reducing the seismic performance of the containment, expanding the accident hazards, insufficient cooling water, etc., so as to improve the ability to resist external events, improve the seismic performance, and increase the pressure bearing capacity. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

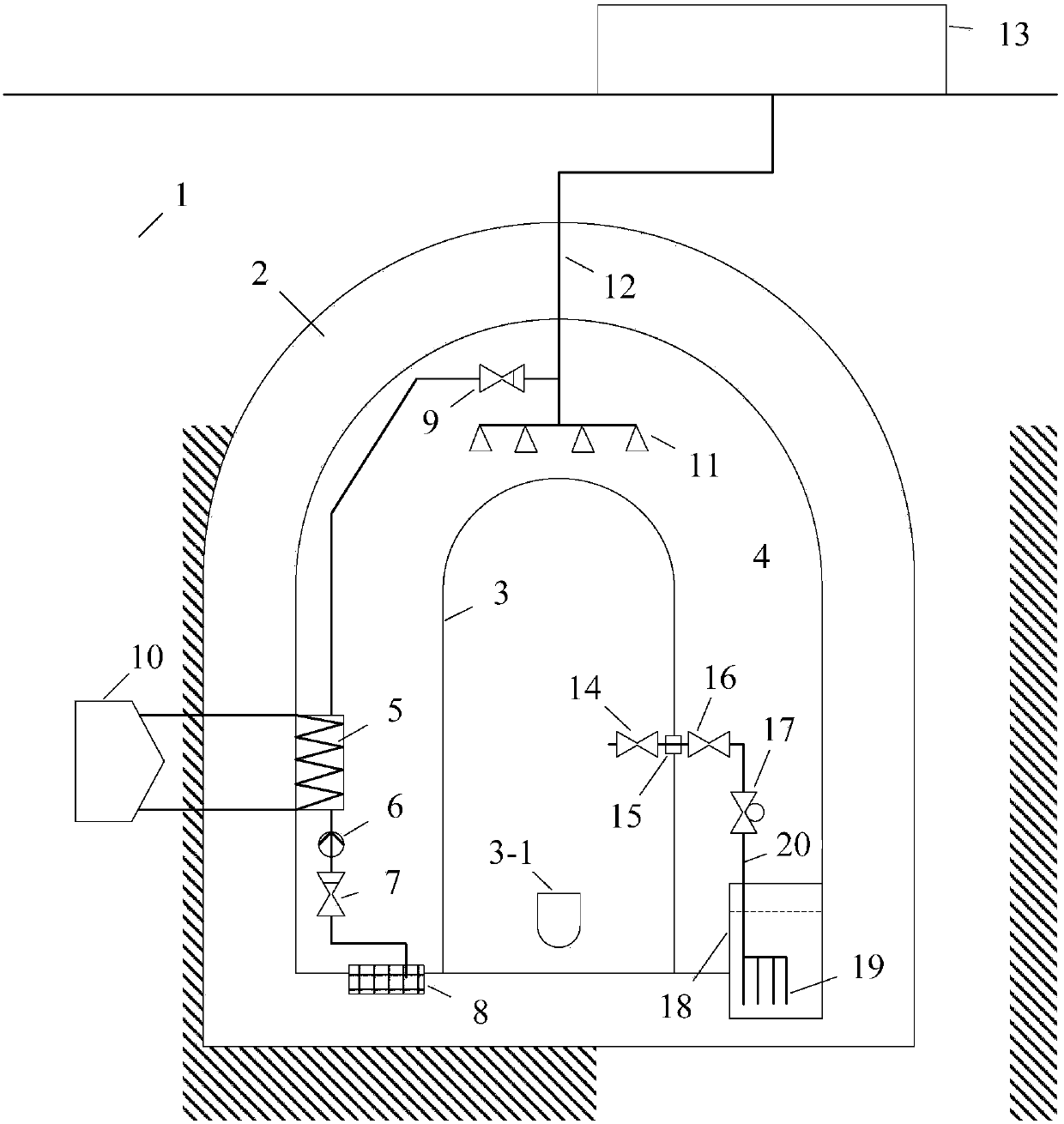

[0022] The present invention is an underground nuclear power plant cavern type double-layer containment such as figure 1 As shown, it includes a surface pool 13 located on the ground and a containment vessel located in the underground rock formation 1 . The containment vessel is provided with an outer rock mass reconstruction layer 2 and an inner steel containment vessel 3 sequentially from the outside to the inside, and the nuclear power plant pressure vessel 3-1 is placed in the inner steel containment vessel 3 . An annular containment interlayer space 4 is formed between the outer rock mass reconstruction layer 2 and the inner steel containment vessel 3 , and a closed circulation heat exchange system is arranged in the containment interlayer space 4 . The clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com