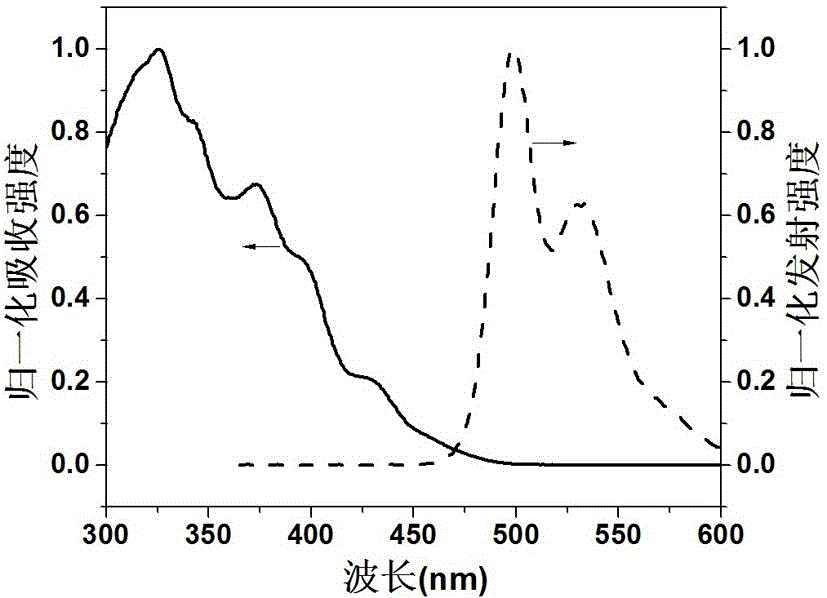

Application of polyphenylene vinylene (PPV) conjugated polymer luminescent nanometer material in latent fingerprint development

A technology of phenylene vinylene and fluorescent nanomaterials, which is applied in the fields of fluorescence/phosphorescence, material excitation analysis, etc., to achieve the effect of simple operation and remarkable developing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

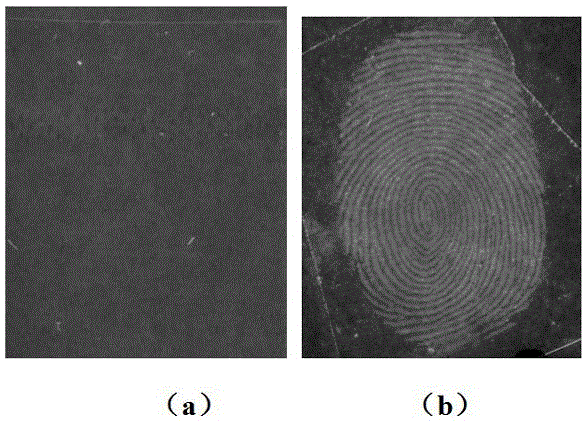

[0025] This embodiment provides a method for developing fresh latent fingerprints on the adhesive surface of fingerprint tape with polymer fluorescent nanoparticle suspension, the specific steps are as follows:

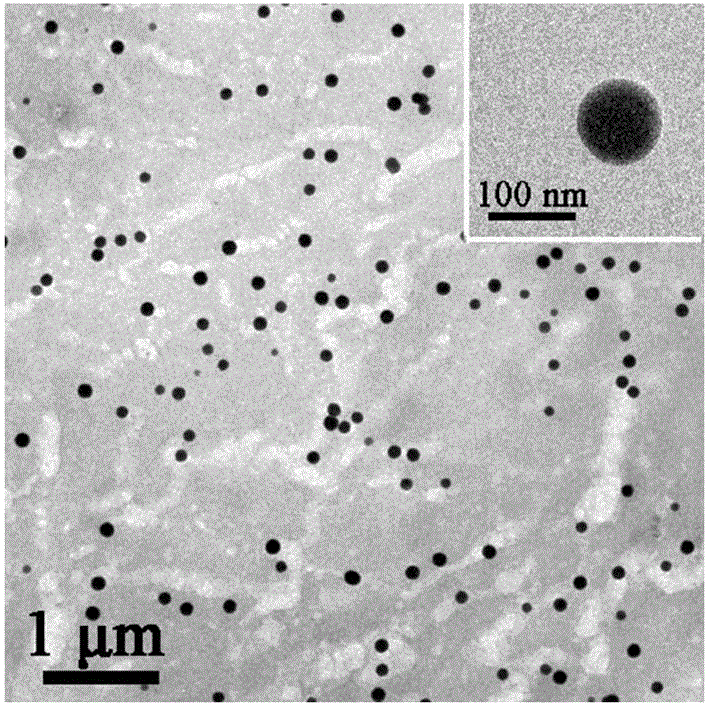

[0026] 1. According to the technical scheme disclosed in the Chinese invention patent (CN104845052A), the poly(p-phenylene vinylene) precursor solution (pre-PPV) was prepared. Take 5 mL of the prepared pre-PPV and put it into a two-necked flask under anaerobic conditions, add 15 mL of deionized water to dilute, add 0.2003 g of sodium dodecylsulfonate SDS (0.0007 mol), raise the temperature to 50 °C, and wait for Sodium dodecylsulfonate was completely dissolved, and then 0.2 mL of triethylamine (0.0014 mol) was added as an elimination reaction catalyst, and the temperature was continued to rise to 80 °C, and the reaction was continued for 3 h to obtain 18 mL of PPV nanoparticle suspension.

[0027] 2. Take 1 mL of the suspension prepared in step 1, add 4 mL of deionize...

Embodiment 2

[0035] 1. According to the technical scheme disclosed in the Chinese invention patent (CN104845052A), prepare poly-p-phenylene vinylene precursor solution (pre-PPV), take 5 mL into a 50 mL two-necked flask under anaerobic conditions, and then add 15 mL to Dilute with deionized water, add 0.2003 g sodium dodecylsulfonate SDS (0.0007 mol) to it, raise the temperature to 50°C to completely dissolve the SDS, then add 0.2 mL triethylamine (0.0014 mol) as a catalyst for the elimination reaction, and continue to raise the temperature To 80 ℃, continue stirring for 3 h to obtain 18 mL of PPV nanoparticle suspension; take 1 mL of the suspension, add 4 mL of deionized water to dilute to obtain a volume of 5 mL of developer, put it in a weighing bottle for later use .

[0036] 2. Store the fingerprint tape loaded with fingerprints at room temperature for 30 days, and then immerse in the developer solution for 5-10 minutes to ensure full contact between fingerprints and nanoparticles.

...

Embodiment 3

[0041] 1. According to the technical scheme disclosed in the Chinese invention patent (CN104845052A), the poly-p-phenylene vinylene precursor solution (pre-PPV) was prepared, and the reaction system was kept in an oxygen-free environment, and 5 mL of the precursor solution was added to 50 mL of Add 15 mL of deionized water to the two-necked flask for dilution, add 0.2003 g of sodium dodecylsulfonate SDS (0.0007 mol) to it, raise the temperature to 50°C to completely dissolve the SDS, then add 0.2 mL of triethylamine (0.0014 mol) As a catalyst for the elimination reaction, continue to heat up to 80 °C, and continue to stir for 3 h to obtain 18 mL of PPV nanoparticle suspension; take 1 mL of the suspension, add 4 mL of deionized water for dilution, and obtain a volume of 5 mL of developing solution, set Reserve in a weighing bottle.

[0042] 2. Completely immerse the yellow sealing tape with fresh fingerprints in the developer solution for 5-10 minutes to ensure full contact bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com