Manufacturing method of black-box high impact test target

An impact test and black box technology, applied in the field of elastic component target preparation, to avoid cell dislocation, good compliance, and stable overall mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

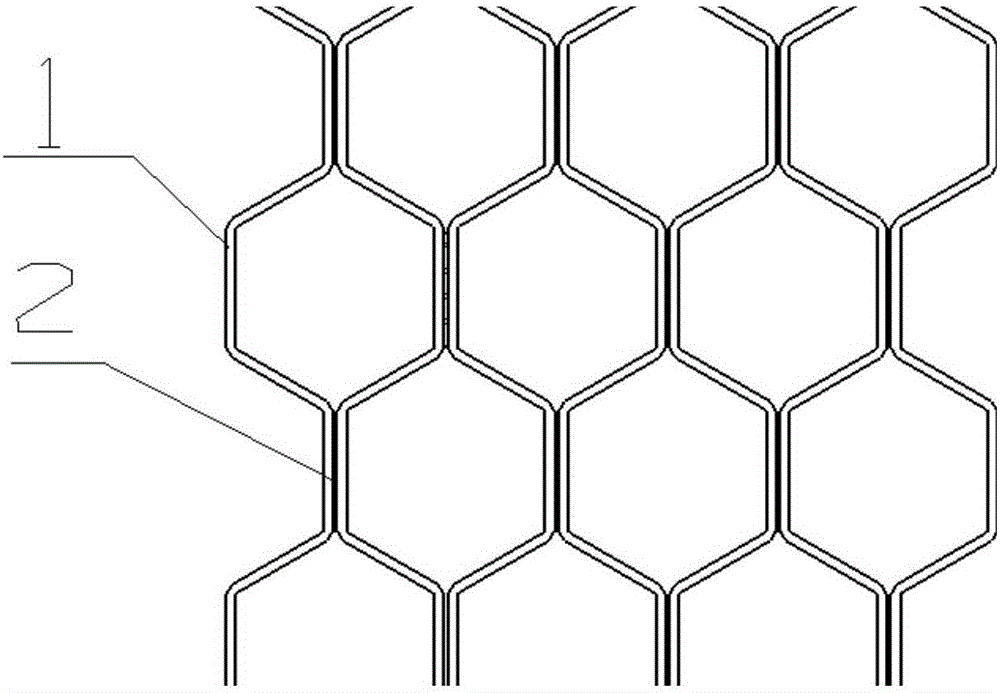

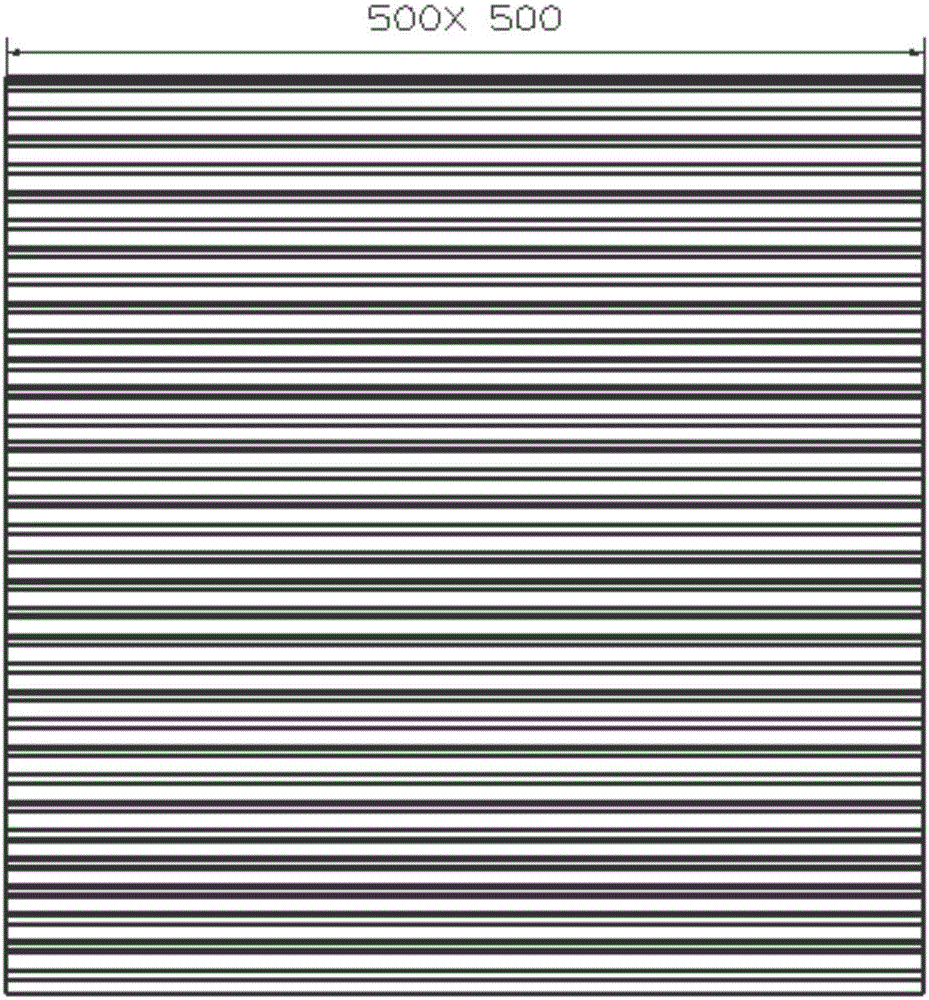

[0030] Refer to Figure 1-Figure 7 . A preparation method of a black box strong impact test target mainly includes the preliminary forming of the semi-honeycomb panel, the overall shaping of the semi-honeycomb panel, the stacking and assembly of the semi-honeycomb panel and the rubber strip, and the overall high-temperature curing, among which:

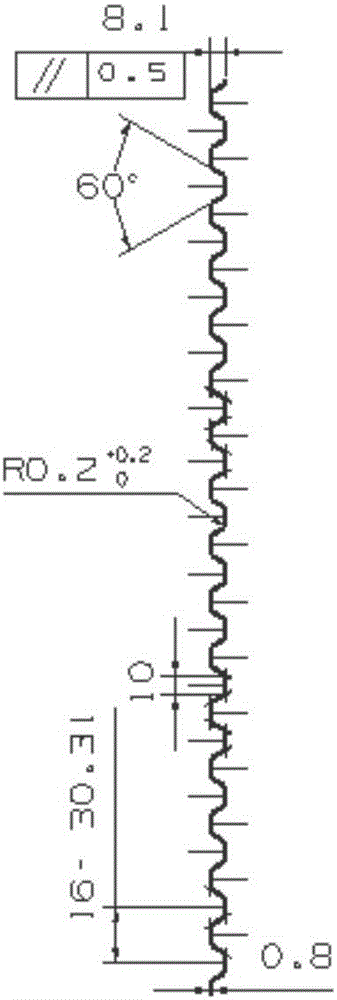

[0031] The preliminary forming of the semi-honeycomb panel uses a multi-station continuous mold combined with a press, and the feeder feeds materials according to the step distance, and is manufactured by multi-station processing. According to the feeding direction from left to right, the multi-station includes fixed-distance feeding, single-tooth honeycomb forming, reserved material slippage, partial shaping and cutting steps.

[0032] Such as figure 2 , image 3 As shown, fixed-distance feeding: the first processing of semi-honeycomb panel 1, the aluminum coil strip is installed on the feeder, and the feeder sends the aluminum coil str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com