Detection device and detection method for detecting tenon staggered teeth of turbine blade

A technology of turbine blades and detection devices, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., which can solve the problems of unsatisfactory detection and processing of turbine working blades for aviation or gas turbines, unstable blade positioning, and cumbersome positioning. , to achieve the effect of light and convenient device, good rotation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

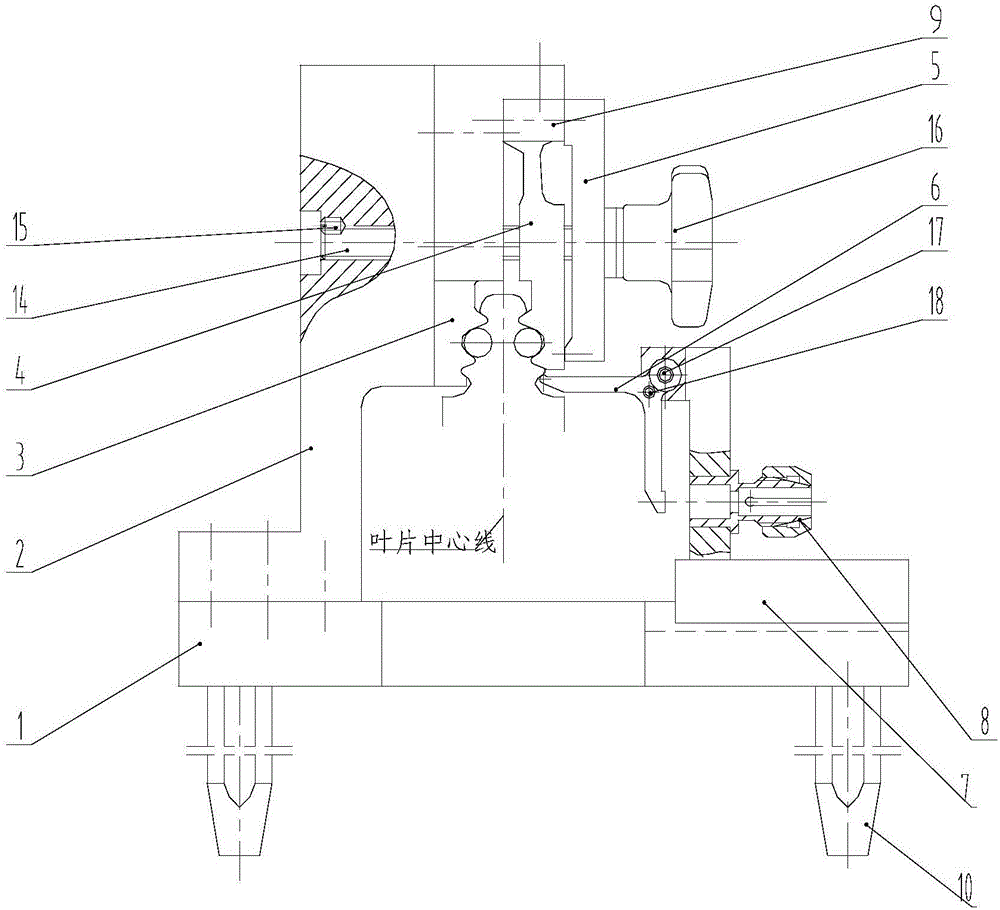

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

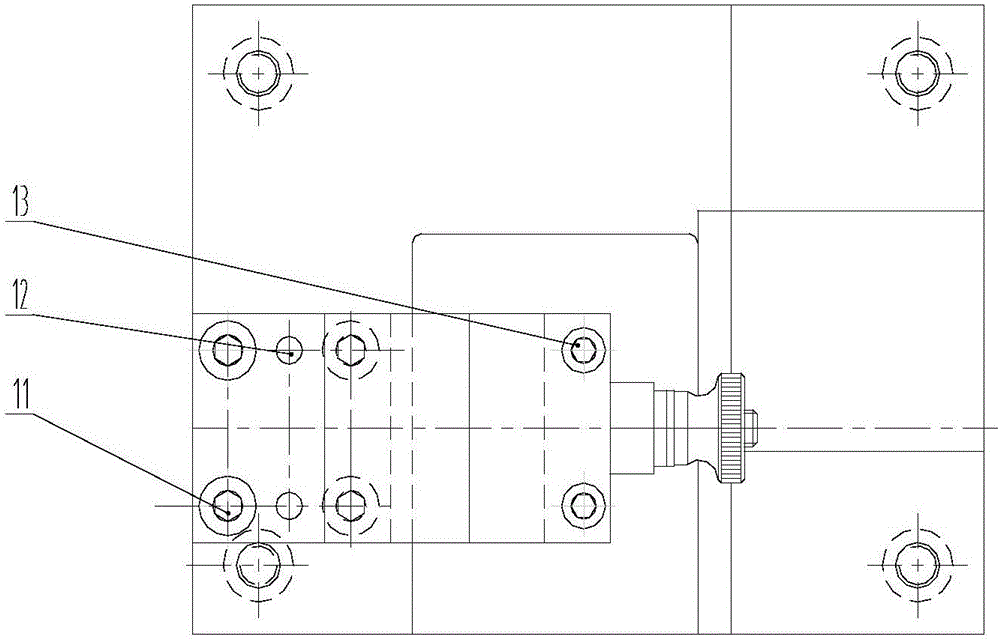

[0029] see figure 1 and figure 2 , the present invention includes a bottom plate 1, and a support plate 2 is fixedly installed on the bottom plate 1 through several first screws 11 and several first cylindrical pins 12. The bottom of the bottom plate 1 is connected with a leg 10 for horizontally placing the device of the present invention on a testing platform.

[0030] A screw 13 , a bolt 14 and a set screw 15 for fixing the bolt 14 are connected to the support plate 2 , and the set screw 15 is perpendicular to the fix bolt 14 . A fixed tooth-shaped block 3 is fixedly installed on the support plate 2, which is used for the main positioning when the mortise and tenon teeth are detected; the fixed tooth-shaped block 3 and the elastic tooth-shaped block 4 are symmetrical, and the two opposite sides are provided with The tooth shape matched with the tenon te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com