Waste heat comprehensive utilization fertilizer granule drying device

A fertilizer granule and drying device technology, which is applied in drying, drying machine, manure drying, etc., can solve the problems of incomplete particle shape, increased operating cost, uneven drying of materials, etc., and achieve uniform turning and drying , Improve the drying effect, improve the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] The embodiment of the present invention includes a drum drying tunnel and a hot air supply mechanism.

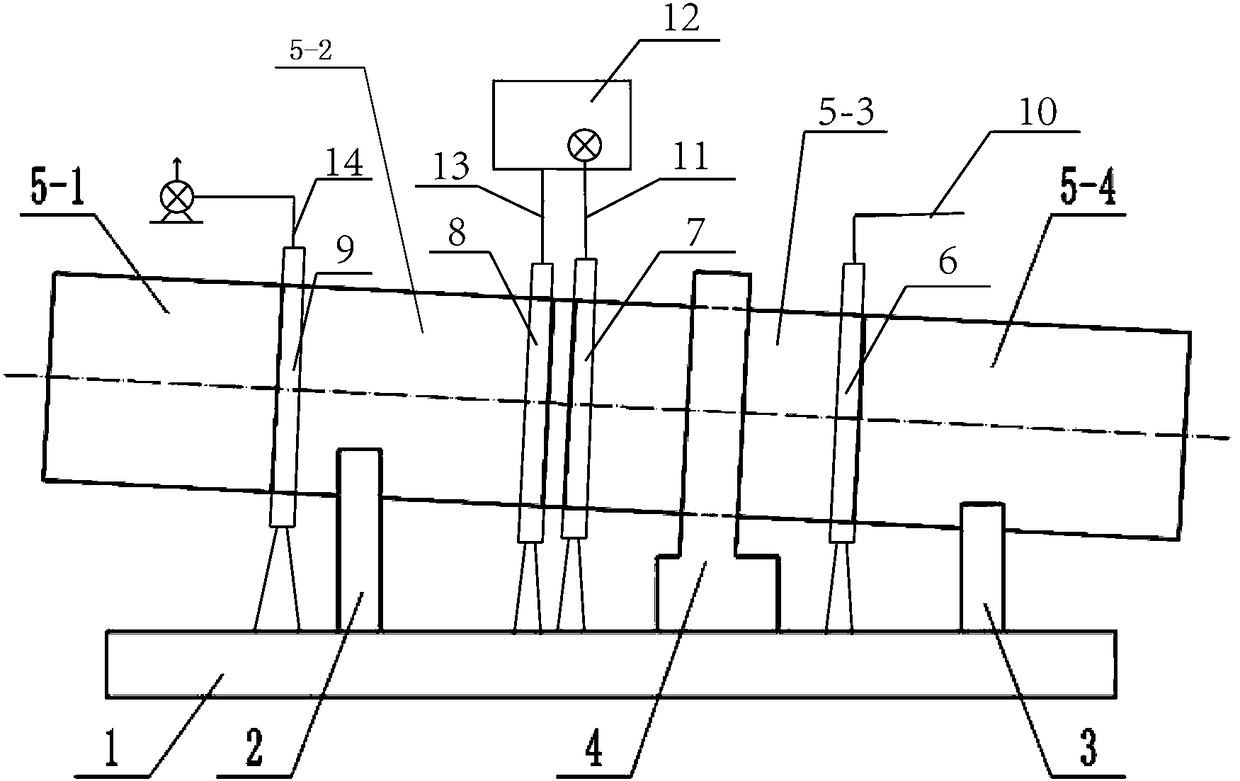

[0024] Such as figure 1 , the drum-type drying tunnel includes a base 1, a support 2 and a support 2 3 installed on the base 1, and is mounted on the support 2 and the support 2 3 through rollers and can rotate relative to the support 2 and the support 2 3 The drum assembly, the base 1 is also installed with a drive device 4 connected to the drum assembly to drive the drum assembly to rotate, the left end of the drum assembly is provided with an inlet, and the right end is provided with an outlet, and the axis of the drum assembly is relative to the horizontal plane It is installed obliquely and the inlet is higher than the outlet, and the inclination angle is 2-5°.

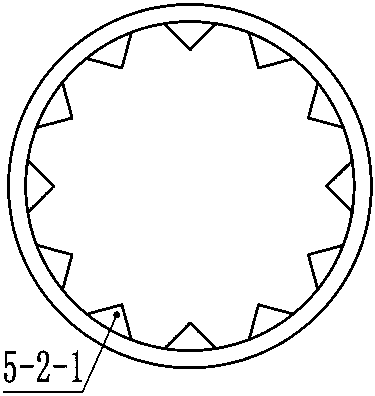

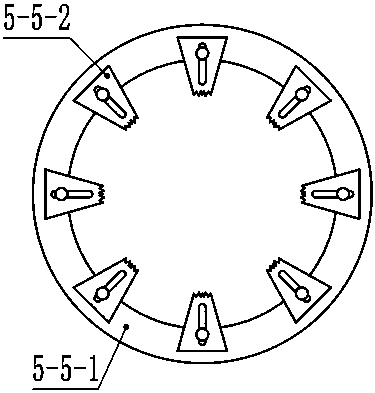

[0025] The drum assembly is composed of a material guide cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com