Biomass hydrolysis acidification device

A technology for hydrolysis, acidification, and biomass, which is applied in biochemical cleaning devices, enzymology/microbiology devices, and biomass post-processing. and other problems, to achieve the effect of facilitating growth and reproduction, reducing temperature fluctuations, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

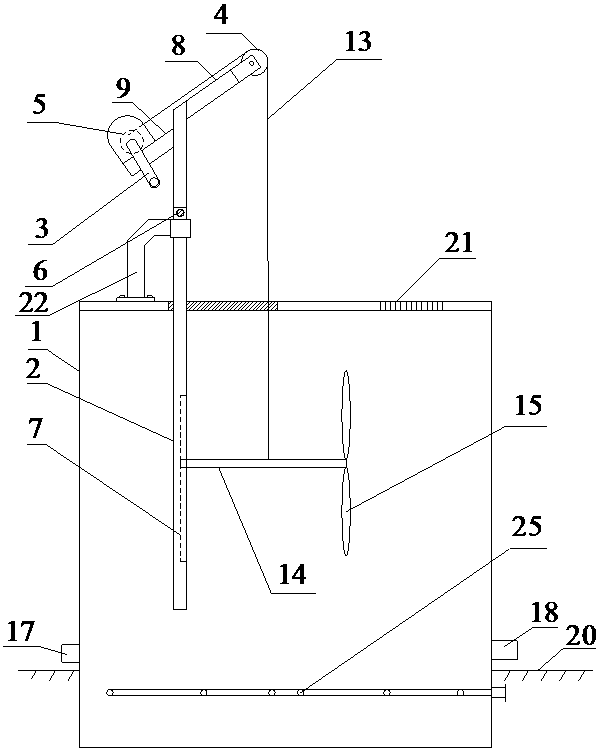

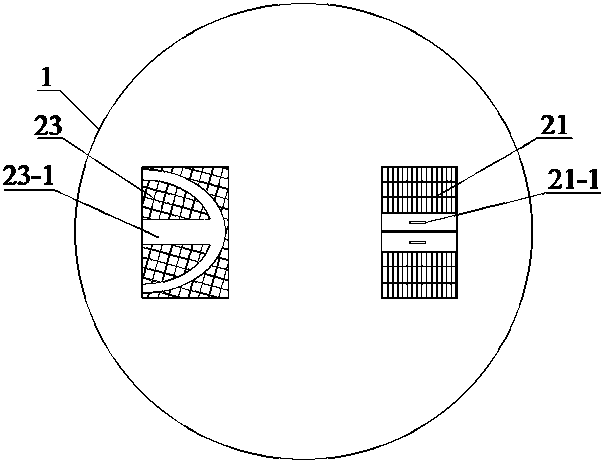

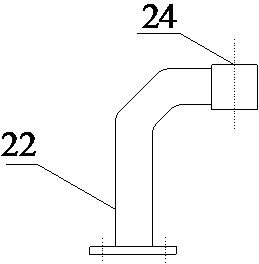

[0029] refer to Figure 1~3 , a biomass hydrolysis and acidification device of the present invention, comprising a tank body 1, a stirring mechanism, an air distribution pipe 25, a feed port 17 and a discharge port 18, the top plate of the tank body 1 is provided with a working window 23 and a ventilation window 21, and the bottom Located below the ground 20, the stirring mechanism includes: a hand-operated elevator, an agitator and a suspension rope 13, the hand-operated elevator passes through the top of the tank body 1 vertically through the working window, and is set away from the center of the tank body 1, and the agitator Slidingly connected with the hand-operated elevator, one end of the suspension rope 13 is connected with the agitator, and the other end is connected with the hand-operated elevator.

[0030]In one embodiment, the tank body 1 is cylindrical, and may also be other shapes commonly used in the art.

[0031] The ventilation window 21 is grid-shaped, and is...

Embodiment 2

[0046] refer to Figure 4 , the biomass hydrolysis and acidification device described in this embodiment is an improvement carried out on the basis of Example 1, and the difference from Example 1 is:

[0047] The air distribution pipe is evenly arranged in the bottom of the tank body 1 in a ring shape, and the distance between the air distribution pipe 25 and the bottom of the tank body 1 can be set according to the process requirements, and its height does not constitute a limitation to the present invention.

[0048] The gas entering the air distribution pipe 25 is air, and the air is pressurized by the pressurized fan and distributed to the air distribution pipe 25 by the gas main pipe 16 regularly and quantitatively according to the process requirements. Air holes 26 to ensure uniform aeration of the feed liquid.

Embodiment 3

[0050] refer to Figure 5 , the biomass hydrolysis and acidification device described in this embodiment is an improvement carried out on the basis of Example 1, and the difference from Example 1 is:

[0051] A connecting ring I10 is arranged on the connecting part I, and the connecting ring I passes through an auxiliary pull piece 12, one end of the auxiliary pull piece is connected to the agitator, and the other end is fixed on the support, the auxiliary pull piece 12 A plurality of connecting rings II11 sufficient to allow the sling to pass are arranged on the pull piece.

[0052] Among them, the connecting ring I10 is used to pass through the auxiliary pull piece 12, and the auxiliary pull piece 12 is made of high-strength engineering plastics.

[0053] The number of connecting rings II 11 can be set to be more than 2, for example, 2, 3, or even more.

[0054] In addition, in order to facilitate the removal of impurities at the bottom of the tank and facilitate maintenan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com