Chlorcosane stabilizer and preparation method thereof

A technology of chlorinated paraffin and stabilizer, applied in the field of chlorinated paraffin stabilizer and its preparation, can solve the problem of relatively few researches on composite stabilizer, achieve good synergistic positive effect, improve thermal stability time, and good processing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

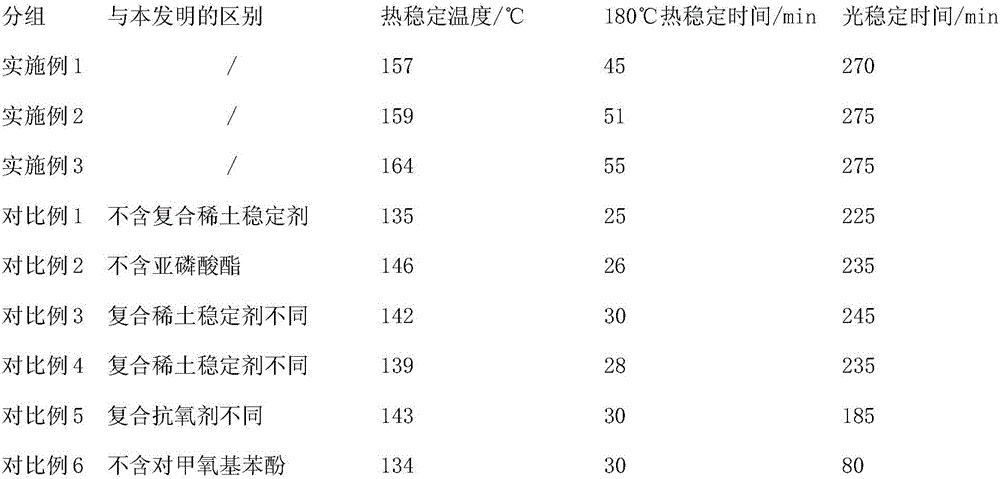

Examples

Embodiment 1

[0036] A chlorinated paraffin stabilizer is made by mixing ethylene glycol diglycidyl ether, composite rare earth stabilizer, phosphite, composite antioxidant, p-methoxyphenol, and ethylene bisstearamide; wherein The weight ratio of ethylene glycol diglycidyl ether, composite rare earth stabilizer, and phosphite is 42:10:5; the composite antioxidant accounts for 1% of the total weight of the stabilizer; p-methoxyphenol accounts for the total weight of the stabilizer 2%; ethylene bis stearamide accounts for 1% of the total weight of the stabilizer; the composite antioxidant is composed of 2,6-di-tert-butyl-p-cresol and thiolauric anhydride with a mass ratio of 1:2 .

[0037] The preparation method of this chlorinated paraffin stabilizer is specifically:

[0038] First, prepare the composite rare earth stabilizer:

[0039] (1) Weigh the raw materials m-dibenzoic acid, cinnamic acid, and α-naphthalene acetic acid in a molar ratio of 3:2:1, mix the three evenly to obtain a mixed...

Embodiment 2

[0046] A chlorinated paraffin stabilizer is made by mixing ethylene glycol diglycidyl ether, composite rare earth stabilizer, phosphite, composite antioxidant, p-methoxyphenol, and ethylene bisstearamide; wherein The weight ratio of ethylene glycol diglycidyl ether, composite rare earth stabilizer, and phosphite is 60:10:6; the composite antioxidant accounts for 2% of the total weight of the stabilizer; p-methoxyphenol accounts for the total weight of the stabilizer 1%; ethylene bis stearamide accounts for 2% of the total weight of the stabilizer; the composite antioxidant is composed of 2,6-di-tert-butyl-p-cresol and thiolauric anhydride with a mass ratio of 1:2 .

[0047] The preparation method of this chlorinated paraffin stabilizer is specifically:

[0048] First, prepare the composite rare earth stabilizer:

[0049] (1) Weigh the raw materials m-dibenzoic acid, cinnamic acid, and α-naphthaleneacetic acid in a molar ratio of 5:3:1, mix the three evenly to obtain a mixed ...

Embodiment 3

[0056] A chlorinated paraffin stabilizer is made by mixing ethylene glycol diglycidyl ether, composite rare earth stabilizer, phosphite, composite antioxidant, p-methoxyphenol, and ethylene bisstearamide; wherein The weight ratio of ethylene glycol diglycidyl ether, composite rare earth stabilizer, and phosphite is 55:10:6; the composite antioxidant accounts for 1.5% of the total weight of the stabilizer; p-methoxyphenol accounts for the total weight of the stabilizer 1%; ethylene bisstearamide accounts for 3% of the total weight of the stabilizer; the composite antioxidant is composed of 2,6-di-tert-butyl-p-cresol and thiolauric anhydride with a mass ratio of 1:2 .

[0057] The preparation method of this chlorinated paraffin stabilizer is specifically:

[0058] First, prepare the composite rare earth stabilizer:

[0059] (1) Weigh the raw materials m-dibenzoic acid, cinnamic acid and α-naphthaleneacetic acid in a molar ratio of 4:3:1, mix the three evenly to obtain a mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com