PVC high strength glove

A high-strength, glove technology, applied in gloves, clothing, applications, etc., can solve the problems of low tensile strength of gloves, tearing of gloves, tearing of gloves, etc., to achieve easy operation, not easy to tear, high tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

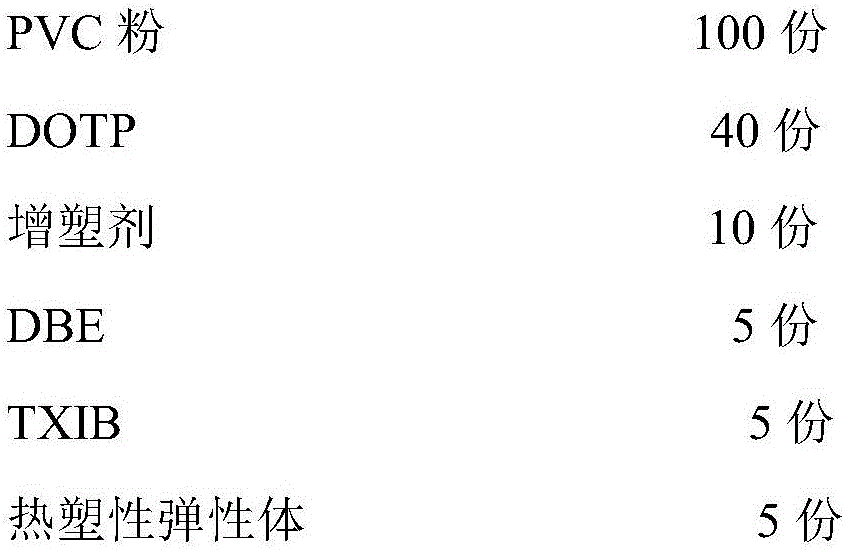

Embodiment 1

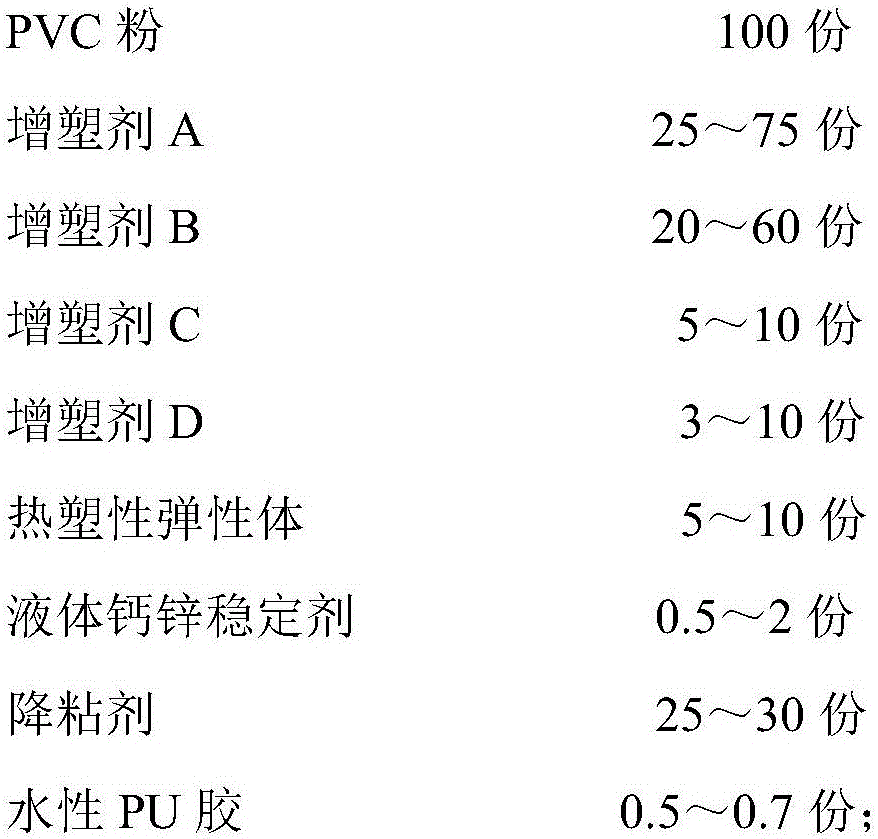

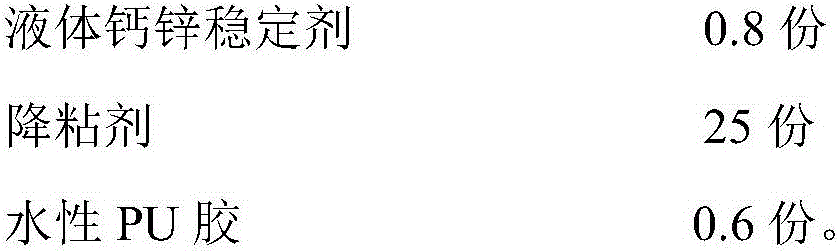

[0036] PVC high-strength gloves are made of the following raw materials in parts by weight:

[0037]

[0038] The production process includes the following steps:

[0039] (1) Primary ingredients: Mix DOTP, K-FLEX 975P, DBE, TXIB and PL-51 and stir, then add PVC powder, CZ-F990, and 10 parts of D70 in turn for stirring to obtain primary ingredients;

[0040] (2) standing defoaming: the primary ingredients are standing defoaming;

[0041] (3) Secondary batching: add 15 parts of D70 to the material prepared in step (2), and stir evenly;

[0042] (4) Primary impregnation: Filter the secondary ingredients prepared in step (3) through at least three layers of 180-mesh filter screens and add them to the material tank. Preheat the hand mold to 65-70°C before impregnating. 46~50℃;

[0043] (5) Primary plasticization: put the impregnated hand mold in an oven, and bake at 170-220°C for 5-8 minutes;

[0044] (6) Second impregnation: add water-based PU glue into softened water and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com