Method for preparing nano high-strength gypsum 3D printing material

A 3D printing and high-strength gypsum technology, which is applied in the field of gypsum, can solve the problems of short residence time of gypsum, low water content of dihydrate gypsum, and low gypsum strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with specific examples.

[0019] A, preparation of nanometer hemihydrate gypsum

[0020] a. Water vapor phase change ultrafine grinding method

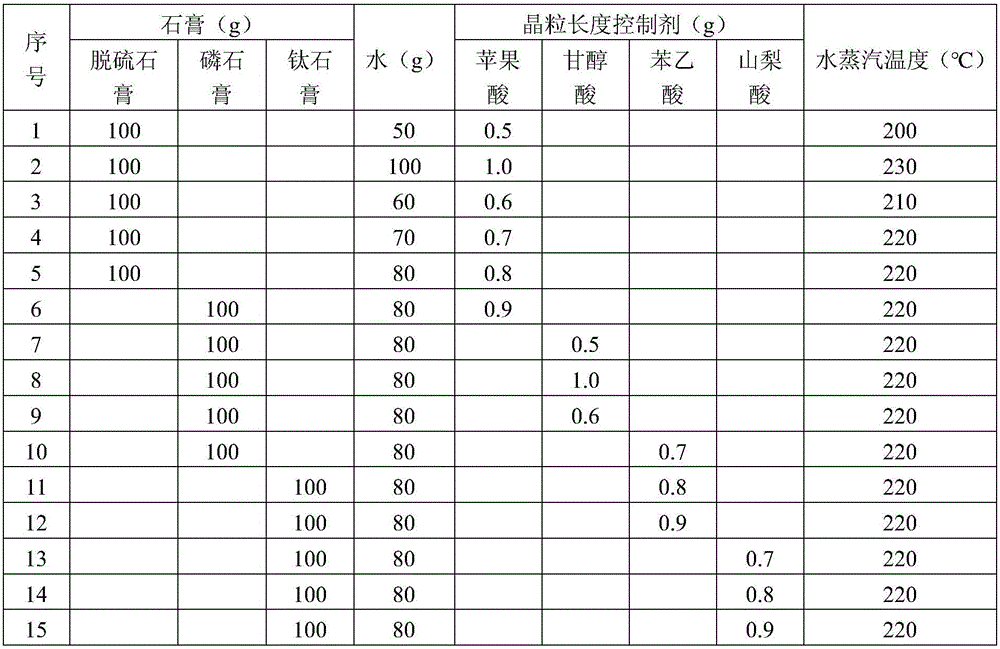

[0021] Add water and a grain length control agent to the gypsum, mix it with a ball mill for 20 minutes, and then send it into a steam phase change ultrafine mill to obtain nanometer hemihydrate gypsum. Table 1 lists 15 examples numbered 1-15.

[0022] Table 1

[0023]

[0024] b. Open system crystallization aid-jet milling method

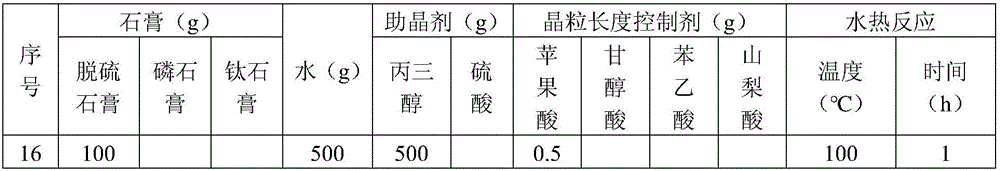

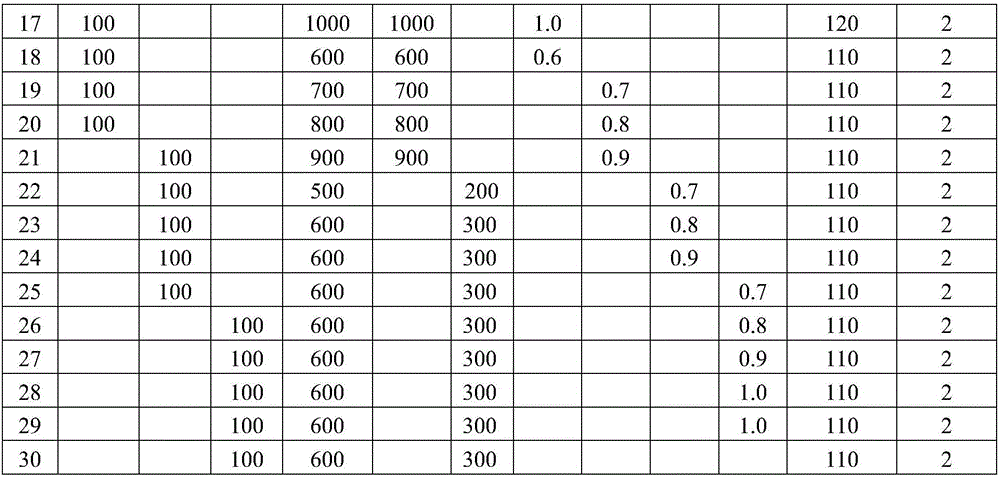

[0025] Put gypsum into the reaction kettle, add water, crystallization aid, grain length control agent, hydrothermal reaction, separate liquid and solid to obtain hemihydrate gypsum, crush and dry the hemihydrate gypsum with hot air jet mill to obtain nano Hemihydrate gypsum. Table 2 lists 15 examples numbered 15-30. see table 2

[0026] Table 2

[0027]

[0028]

[0029] c. Autoclaved hydrothermal-jet mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com