Preparation method of beta-nickel hydroxide nanosheets

A technology of nickel hydroxide and nanosheets, which is applied in the field of preparation of β-nickel hydroxide nanosheets, can solve the problems of unsuitability for industrial production, uneven microwave heating, complex synthesis equipment, etc., and achieve high reproducibility, low cost, The effect of high detection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment relates to a preparation method of β-nickel hydroxide nanosheets, comprising the following steps:

[0032] (1) cleaning treatment of copper rod: copper rod is cleaned under ultrasonic condition with the dilute hydrochloric acid of acetone, ethanol, 2mol / L, distilled water respectively;

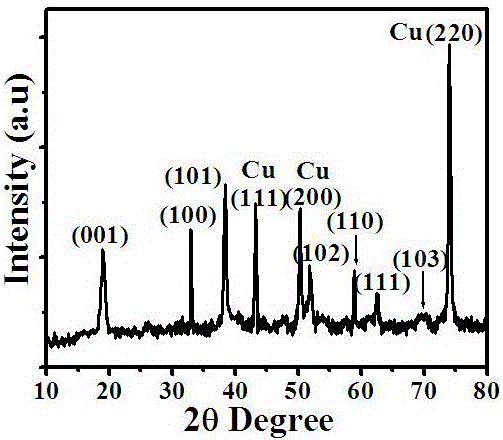

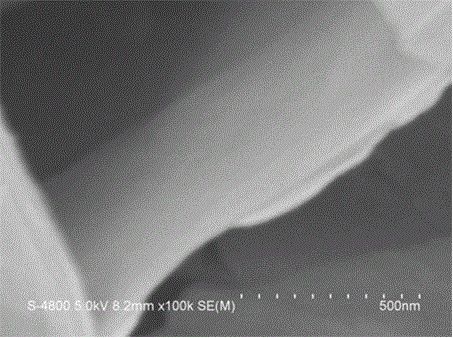

[0033] (2) Preparation of cuprous sulfide nano roses: at room temperature, 4.75g of NiCl 2 ·6H 2 O was dissolved in 100mL distilled water and configured as 0.2mol / L NiCl 2 solution, for use; at room temperature, dissolve 0.8g of sodium hydroxide in 100mL of distilled water to make a 0.2mol / L sodium hydroxide solution for use; use a graduated cylinder to measure 20mL of 0.2mol / L NiCl 2 Pour the solution into the reaction kettle, then pour 20mL of 0.2mol / L sodium hydroxide solution, stir to make the solution evenly mixed, and the cleaned cross-sectional area is 3.5mm 2 , Put the copper rod with a length of 6cm into the reaction kettle, seal the reaction kettle, and reac...

Embodiment 2

[0036] This embodiment relates to a preparation method of β-nickel hydroxide nanosheets, comprising the following steps:

[0037] (1) cleaning treatment of copper rod: copper rod is cleaned under ultrasonic condition with the dilute hydrochloric acid of acetone, ethanol, 2mol / L, distilled water respectively;

[0038] (2) Preparation of cuprous sulfide nano roses: at room temperature, 4.75g of NiCl 2 ·6H 2 O was dissolved in 100mL distilled water and configured as 0.2mol / L NiCl 2 solution, for use; at room temperature, dissolve 0.8g of sodium hydroxide in 100mL of distilled water to make a 0.2mol / L sodium hydroxide solution for use; use a graduated cylinder to measure 20mL of 0.2mol / L NiCl 2 Pour the solution into the reaction kettle, then pour 20mL of 0.2mol / L sodium hydroxide solution, stir to make the solution evenly mixed, and the cleaned cross-sectional area is 3.5mm 2 , Put the copper rod with a length of 6cm into the reactor, seal the reactor, and react at 180°C for 8 h...

Embodiment 3

[0041] This embodiment relates to a preparation method of β-nickel hydroxide nanosheets, comprising the following steps:

[0042] (1) cleaning treatment of copper rod: copper rod is cleaned under ultrasonic condition with the dilute hydrochloric acid of acetone, ethanol, 2mol / L, distilled water respectively;

[0043] (2) Preparation of cuprous sulfide nano roses: at room temperature, 4.75g of NiCl 2 ·6H 2 O was dissolved in 100mL distilled water and configured as 0.2mol / L NiCl 2 solution, for use; at room temperature, dissolve 0.8g of sodium hydroxide in 100mL of distilled water to make a 0.2mol / L sodium hydroxide solution for use; use a graduated cylinder to measure 20mL of 0.2mol / L NiCl 2 Pour the solution into the reaction kettle, then pour 20mL of 0.2mol / L sodium hydroxide solution, stir to make the solution evenly mixed, and the cleaned cross-sectional area is 3.5mm 2 , Put the copper rod with a length of 6cm into the reactor, seal the reactor, and react at 180°C for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com