Semi-automatic wharf high-speed heavy-duty track and wharf loading and unloading system layout

A semi-automatic and wharf technology, applied in storage devices, transportation and packaging, mechanical conveyors, etc., it can solve the problems of inability to use heavy loads for a long time, affecting the efficiency of port operations, and long supply time for electrical energy consumption, saving processing and design. cost, saving charging time, optimizing the effect of the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

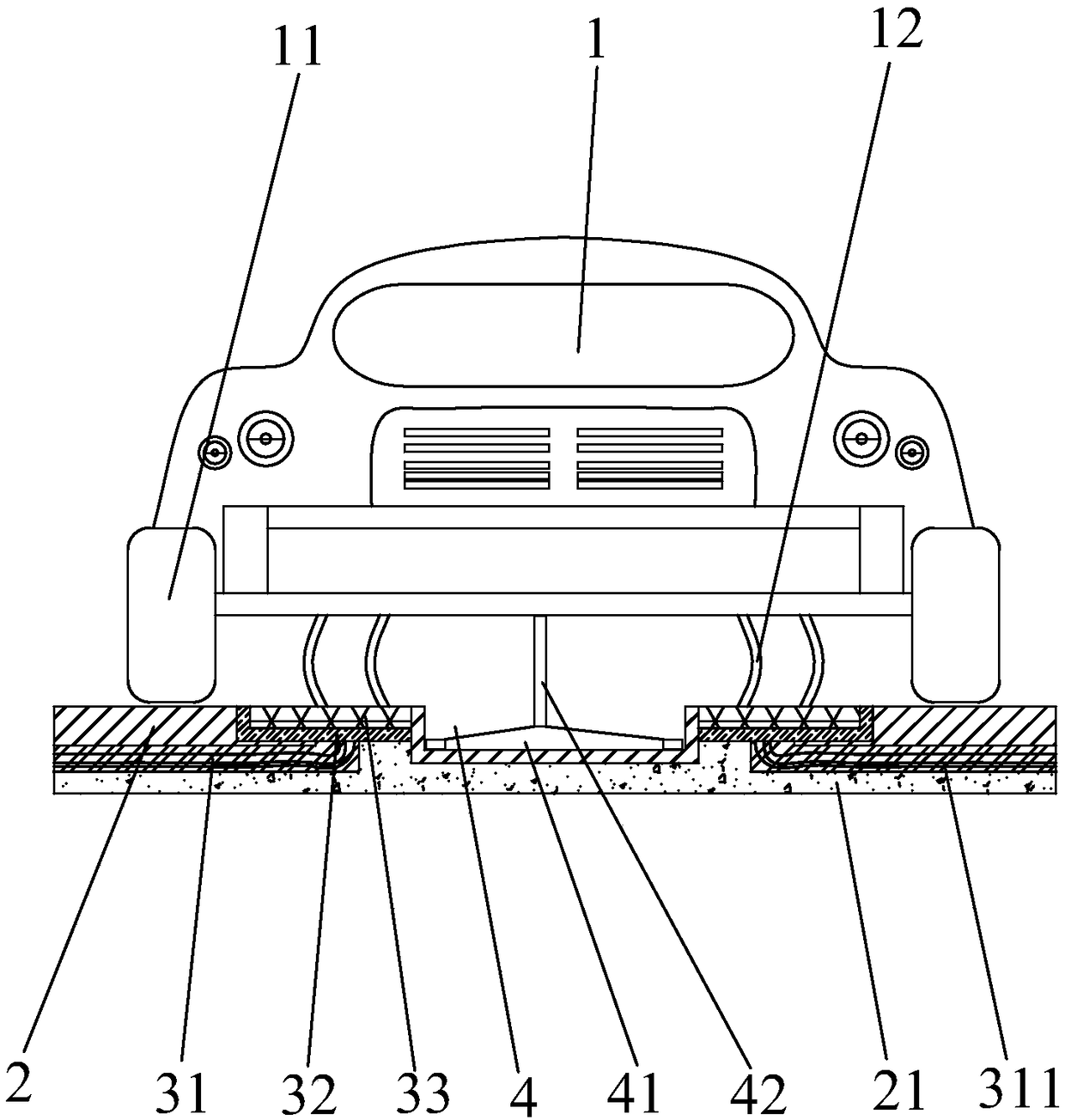

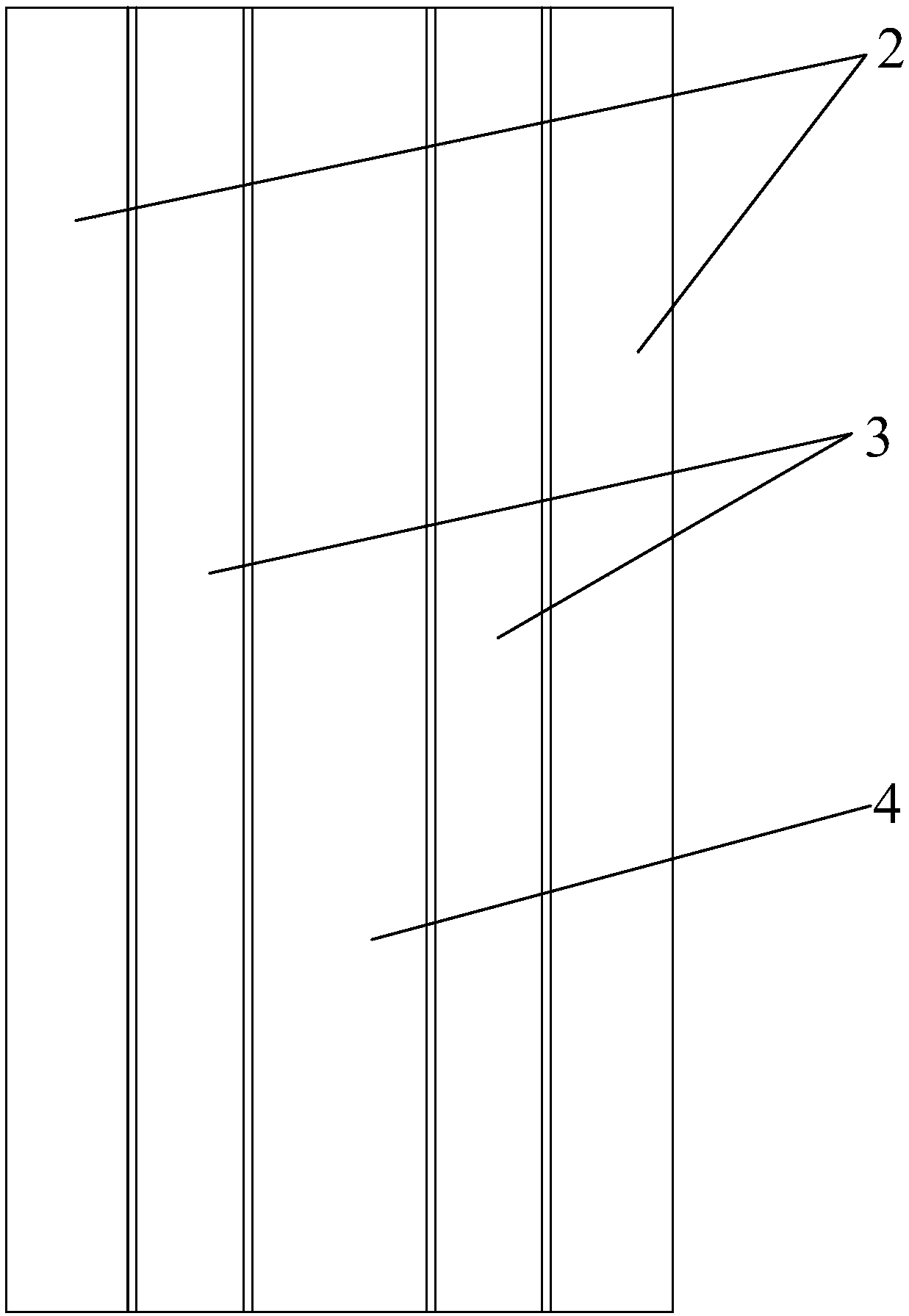

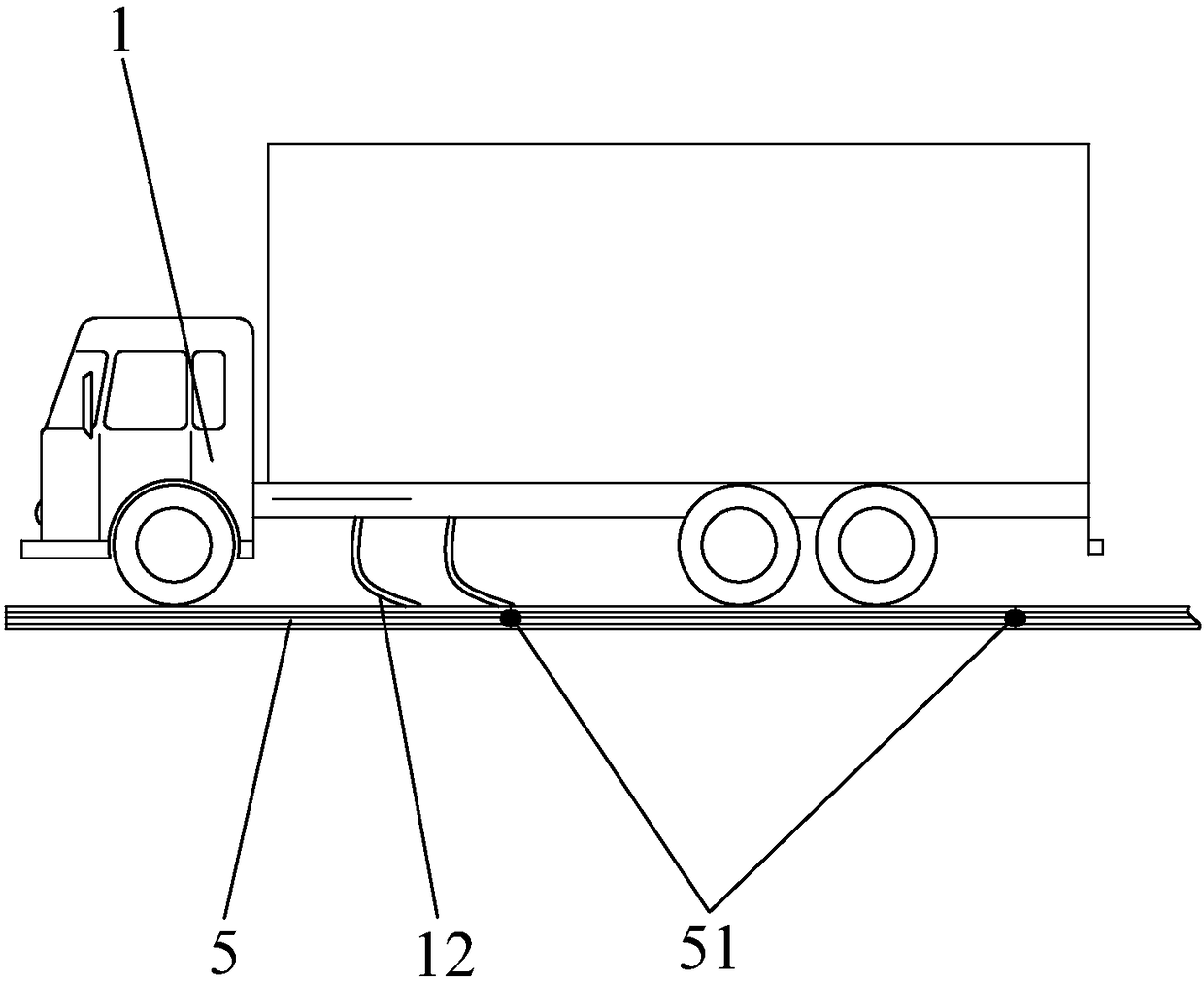

[0024] Such as figure 1 , figure 2 and image 3 As shown, the high-speed heavy-duty track of the semi-automatic terminal of the present invention includes a guide slot 4 positioned at the center of the track, and an inertial guide is provided in the guide slot 4, and the AGV1 drives the inertia guide to advance in the direction in which the track extends; the guide slot 4 Both sides are symmetrically provided with contact wire pan-tilts 3 , and the outer sides of the contact wire pan-tilts 3 are attached to the edge of the conventional road surface 2 respectively, and the wheels 11 of the AGV1 travel on the conventional road surface 2; Connected to the touch lead gimbal 3, the touch lead gimbal 3 supplies power to the AGV1 to provide driving power, and the electric energy drives the design of the AGV1 to travel. Compared with the fuel trucks at the conventional wharf, the carbon emission has dropped significantly by about 20%. Optimized The port transportation environment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com