A 3D printing manufacturing method for smart bottle caps that can display shelf life

A 3D printing and bottle cap technology, which is applied in the direction of additive manufacturing, manufacturing tools, 3D object support structures, etc., can solve the problems of difficult identification, alteration, blurring, etc., and achieve simple operation, high safety and low equipment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

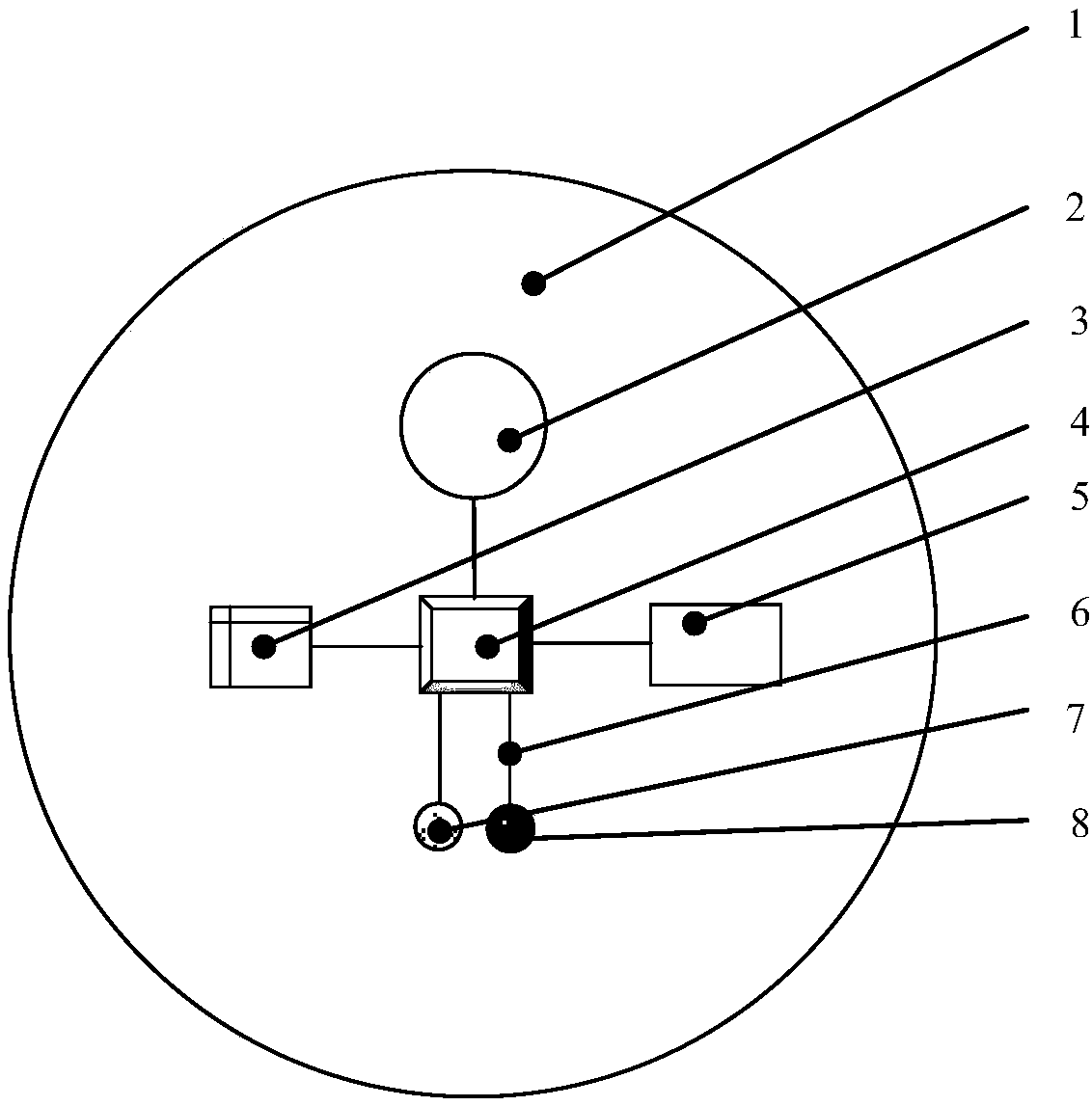

[0038] Such as figure 1 As shown, the smart bottle cap includes: a cover body 1, a power supply device (the battery 2 is selected in the present embodiment), a clock circuit 3, a controller (the single-chip microcomputer 4 is selected in the present embodiment), and a time display element (the LED digital digital display is selected in the present embodiment) Pipe 5, also can select other elements such as display screen for use), connecting circuit 6, first indicator light (present embodiment selects red LED indicator light 7), second indicator light (present embodiment selects green LED indicator light 8). Among them, battery 2, clock circuit 3, single-chip microcomputer 4, LED digital tube 5, connecting circuit 6, red LED indicator light 7, and green LED indicator light 8 are all embedded in the cover body 1 of the smart bottle cap. Tube 5, red LED indicator light 7, green LED indicator light 8 are connected to single-chip microcomputer 4 through connection circuit 6, batter...

Embodiment 2

[0041] A container includes a bottle body, and the smart bottle cap as described in Embodiment 1 is arranged on the sealing part of the bottle body.

[0042] The container in this embodiment can hold beer or drops or drinks or medicines or gifts or condiments and the like.

Embodiment 3

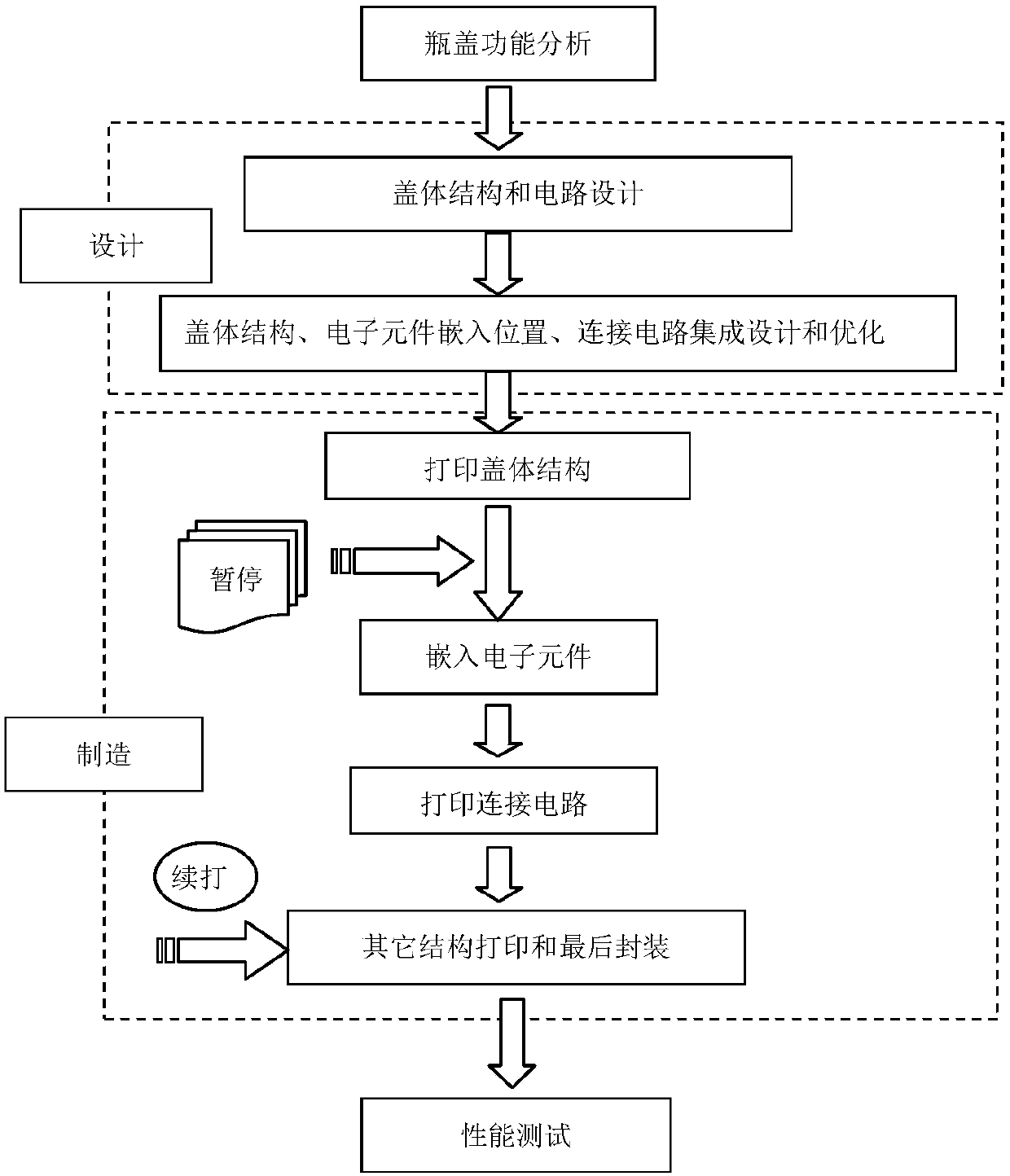

[0044] The method of using 3D printing to manufacture smart bottle caps: first, use fused deposition (FDM) 3D printing to manufacture the cap body structure; then, use the interrupt / pause function of fused deposition 3D printing to place the electronic components that need to be embedded into the cap body structure ; Subsequently, the conductive silver paste is used as the printing material, and the connecting circuit is printed using the electrojet printing 3D printing process; finally, the printing of other structures of the bottle cap and the final packaging are completed by fused deposition 3D printing.

[0045] Such as figure 2 As shown, the specific process of manufacturing smart bottle caps based on 3D printing:

[0046] Step 1: Cover structure and circuit design; first, according to the functional requirements of the smart bottle cap, carry out cover structure design and circuit design respectively; then, carry out cover structure 1, embed electronic components (batte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com