Low-temperature heat sealing polyolefin thin film and preparation method thereof

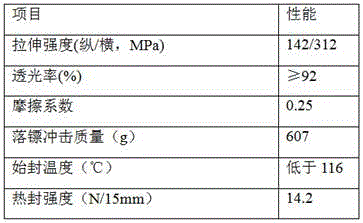

A low-temperature heat-sealing, polyolefin technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of low initial sealing temperature and heat sealing strength, and achieve ultra-low initial sealing temperature, High heat-seal strength and improved processing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A low-temperature heat-sealing polyolefin film, comprising a corona layer, a core layer and a heat-sealing layer from top to bottom; the corona layer is PP resin without processing aids, and the core layer is composed of: homopolymer 97.5wt% of polypropylene, 0.1wt% of blocking agent, 2.4wt% of slippery agent; Its composition of described heat-sealing layer is: PBE elastomer 70wt%, metallocene linear low density polyethylene 19wt%, LDPE 5wt% , nano silicon dioxide 1.0wt%, smooth agent 5.0wt%.

[0047] The low-temperature heat-sealing polyolefin film, wherein, the ratio of each layer is: corona layer 8wt%, core layer 84wt%, heat-sealing layer 8wt%.

[0048] The preparation method of low-temperature heat-sealing polyolefin film as mentioned above, concrete steps are:

[0049] (1) The raw materials of corona layer, core layer and heat-sealing layer are measured according to the formula ratio and mixed evenly;

[0050] (2) Add the three mixed raw materials into the extrud...

Embodiment 2

[0053] A low-temperature heat-sealing polyolefin film, comprising a corona layer, a core layer and a heat-sealing layer from top to bottom; the corona layer is PP resin without processing aids, and the core layer is composed of: homopolymer 98wt% polypropylene, 0.2wt% anti-blocking agent, 1.8wt% smoothing agent, the raw material composition of the heat-sealing layer is: 45wt% PBE elastomer, 49wt% metallocene linear low density polyethylene, 3wt% LDPE, nano Silicon dioxide 1.0wt%, slip agent 2.0wt%.

[0054]The low-temperature heat-sealed polyolefin film has a ratio of each layer: 10wt% of the corona layer, 80wt% of the core layer, and 10wt% of the heat-sealing layer.

[0055] The preparation method of low-temperature heat-sealing polyolefin film as mentioned above, concrete steps are:

[0056] (1) The raw materials of the three layers of corona layer, core layer and heat-sealing layer are measured according to the formula ratio and mixed evenly;

[0057] (2) Add the three mi...

Embodiment 3

[0060] A low-temperature heat-sealing polyolefin film, comprising a corona layer, a core layer and a heat-sealing layer from top to bottom; the corona layer is PP resin without processing aids, and the core layer is composed of: homopolymer 98.5wt% polypropylene, 0.3wt% anti-blocking agent, 1.2wt% slippery agent, the raw material composition of the heat-sealing layer is: 45wt% PBE elastomer, 45wt% metallocene linear low density polyethylene, 4wt% LDPE, nano Silicon dioxide 3.0wt%, slip agent 3.0wt%.

[0061] The low-temperature heat-sealed polyolefin film has a proportion of each layer: 15wt% of the corona layer, 70wt% of the core layer, and 15wt% of the heat-sealing layer.

[0062] The preparation method of low-temperature heat-sealing polyolefin film as mentioned above, concrete steps are:

[0063] (1) The raw materials of the three layers of corona layer, core layer and heat-sealing layer are measured according to the formula ratio and mixed evenly;

[0064] (2) The three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com