Profiling stripping structure applied to die opening engineering of U-shaped workpiece drawing die

A technology for drawing dies and workpieces, applied in the field of stamping and forming dies, can solve problems such as damage to skirts, and achieve the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

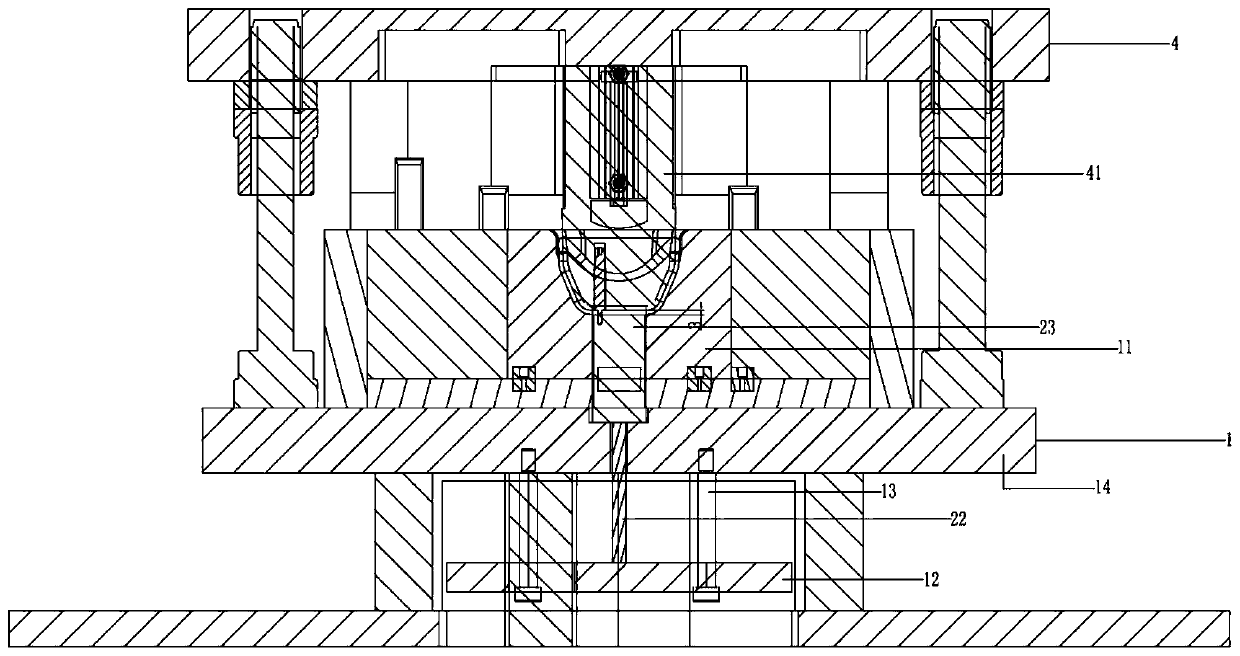

[0023] see Figure 1 to Figure 4 , the figure shows a profiling stripping structure applied to the U-shaped workpiece drawing die opening project provided by Embodiment 1 of the present invention. The U-shaped workpiece 3 has skirts 31 on both sides in the width direction. The shape stripping structure includes a profile stripping mechanism 2 installed on the lower die mechanism 1. The profile stripping mechanism 2 includes an upper top drive part 22 and a profile stripping block 23. The top top drive part 22 is a driving cylinder. The shape stripping block 23 is initially located in the preset space in the punch 11 of the lower die mechanism 1, and the driving shaft 225 of the top driving part 22 is connected to the profiling stripping block 23, and the driving shaft 225 is a V-shaped bending structure , the upper top driving part 22 drives the profiling stripping block 23 to go up and pushes the U-shaped workpiece 3 toward the direction of the punch 41 that is offset from th...

Embodiment 2

[0028] see Figure 1 to Figure 4 , the figure shows a profiling stripping structure applied to the U-shaped workpiece drawing die opening project provided by the second embodiment of the present invention. This embodiment further makes the following on the basis of the above embodiment As an improved technical solution: in the mold closing state, there is a gap of 3-4mm between the top surface of the profiling stripping block 23 and the punch 41, by setting the gap, the profiling stripping block can be Indent a section to prevent the punch from damaging the profiling stripping block.

Embodiment 3

[0030] see Figure 1 to Figure 4 , the figure shows a profiling stripping structure applied to the U-shaped workpiece drawing die opening project provided by the third embodiment of the present invention. This embodiment further makes the following on the basis of the above embodiments As an improved technical solution: an upper air intake chamber 222 and a lower air intake chamber 223 are arranged in the cylinder block 221 of the driving cylinder; 222 deflates, and the drive shaft 225 drives the profiling stripping block 23 to retract; when the mold is opened, the control valve controls the lower air intake cavity 223 to deflate, and at this time, the upper air intake cavity 222 intakes air, and the drive rod drives the profiling stripping block Block 23 protrudes and ejects U-shaped workpiece 3 . Through the setting of the above structure, when the drive shaft is retracted, the air intake in the lower air intake chamber can make the bottom of the entire cylinder more stable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bend angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com