Bottle washing apparatus for pilot scale production

A kind of equipment and bottle washing technology, which is applied in the direction of chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of increasing secondary pollution of controlled glass bottles, low cleaning speed, cumbersome manual operation, etc. Achieve the effect of reducing the risk of secondary pollution, high cleaning efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

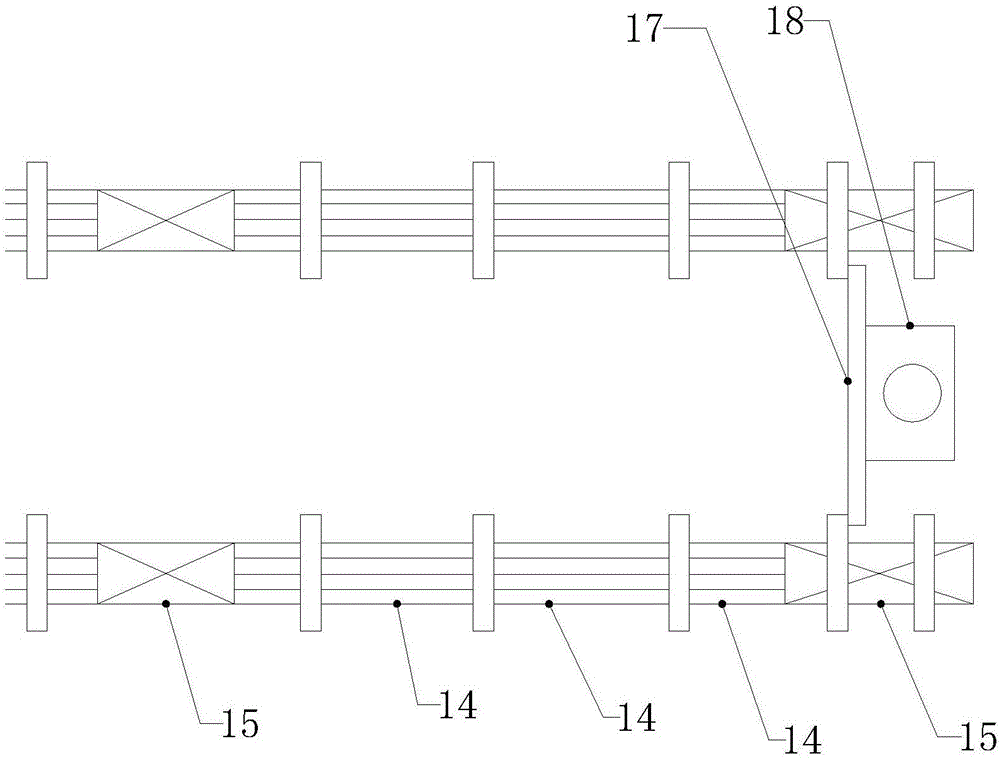

[0025] see Figure 1 to Figure 3 , a kind of pilot-scale production bottle washing equipment of a preferred embodiment of the present invention, comprises conveying mechanism and cleaning mechanism, and conveying mechanism comprises bottle unscrambler 1 and bottle conveying track 2, and cleaning mechanism comprises cabinet 3 and water for injection tank 4 , the upper part of the inner cavity of the chassis is provided with the first water outlet tank 5, the ultrasonic cleaning tank 6, the second water outlet tank 7, the purified water cleaning tank 8, the injection water rinsing tank 9 and the drying tank 10, and the ultrasonic water adding tank is arranged in the cabinet....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com