Plastic-coating method for large-diameter steel tube

A technology of large-diameter and steel pipes, which is applied in the field of plastic coating of large-diameter steel pipes, can solve the problems of long time consumption and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

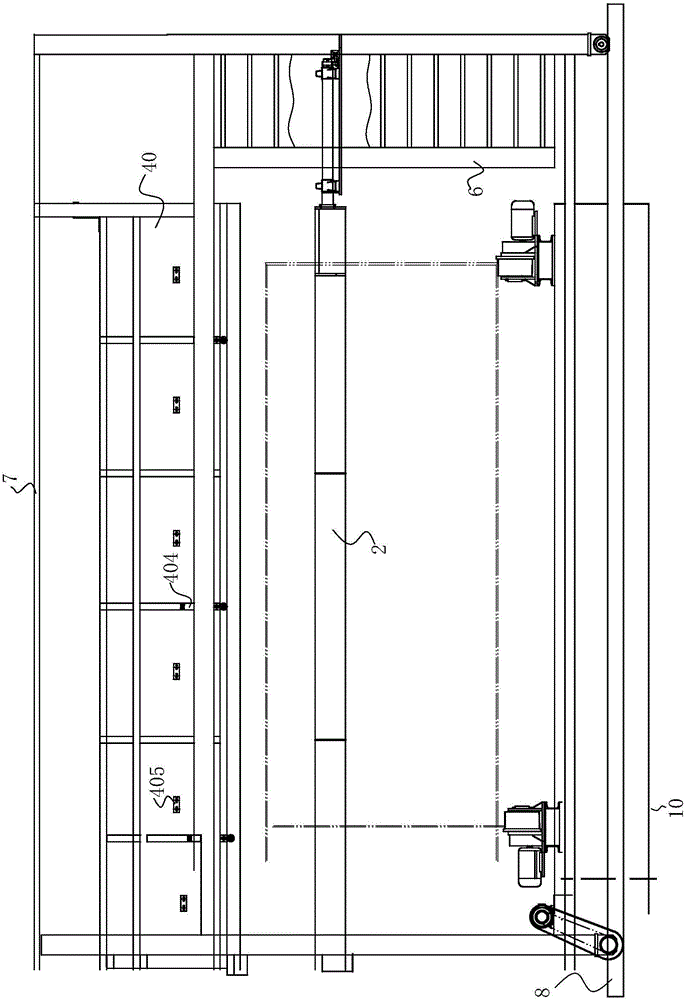

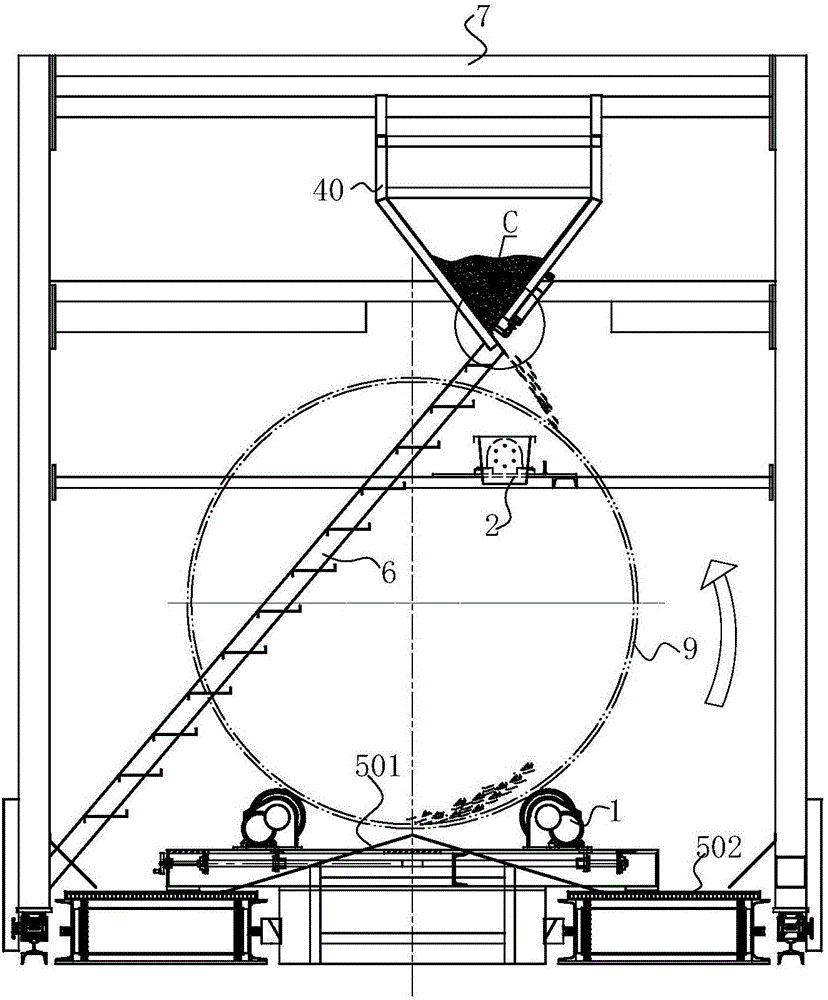

[0039] combine figure 1 , figure 2 , Figure 6 as well as Figure 7 As shown, a large-diameter steel pipe plastic coating equipment includes an underframe 10, and the underframe 10 is provided with a steel pipe rotating device 1. The steel pipe rotating device 1 has two groups for supporting the two ends of the steel pipe 9, and each group of steel pipe rotating device 1 includes a support seat 105, which is installed on the chassis 10, and the support seat 105 is rotatably equipped with two side-by-side The rollers 103 are all driving rollers 103, adopting a four-drive mode, which can effectively avoid the slipping phenomenon between the steel pipe 9 and the rollers 103 during the plastic coating process.

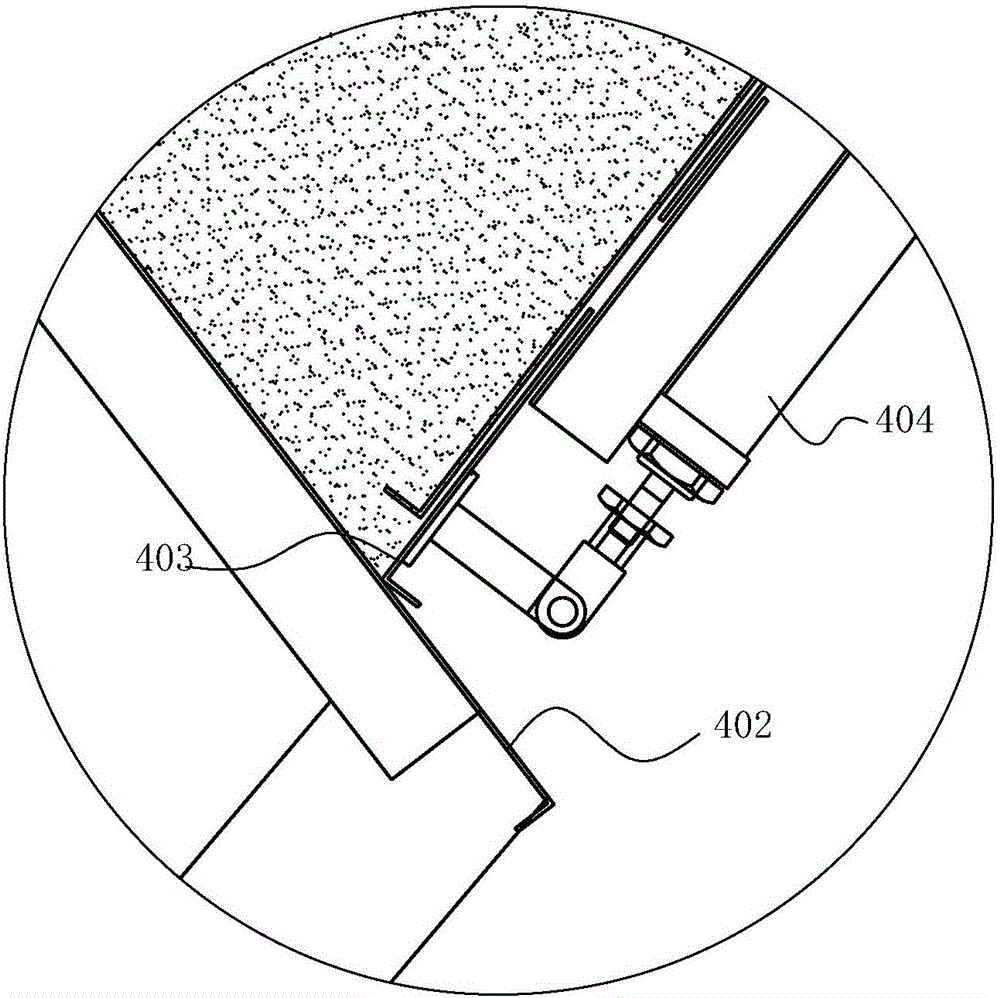

[0040] The outer peripheral surface of the roller 103 is provided with anti-slip teeth 109, and a groove for containing plastic powder is provided between adjacent anti-slip teeth 109. When the steel pipe 9 is coated with plastic, the temperature is generally about 280...

Embodiment 2

[0056] to combine Figure 8 and Figure 9 Commonly shown, there are two walking frames 7, and the two walking frames 7 are provided with a powder material trough 40 and a hopper 22. During operation, the two walking frames 7 advance from the two ends of the steel pipe 9 to their respective working positions. After the blanking is completed, the two walking frames 7 return backwards. The large-diameter steel pipe 9 is plastic-coated by using two walking frames 7 in combination, and the steel pipe 9 with a longer length can be plastic-coated.

[0057] In the present invention, the turning hopper 22 is turned over to feed the powder and the powder chute 40 is used to coat the inside and outside of the rotating steel pipe 9 with plastic, which improves the coating speed of the steel pipe 9 and makes the coating of the steel pipe 9 uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com