Catalyst used for pentanoate bio-fuel production, and method for inhibiting carbon deposit of catalyst

A biofuel and production method technology, applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of high cost of catalyst precursors, complex catalyst preparation process, etc., to achieve the suppression of catalyst carbon deposition, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Ni / K / ZrO 2 Catalyst preparation: 1g ZrO 2 Add the powder into an aqueous solution of potassium nitrate with a concentration of about 0.006mol / L and stir for 24 hours, then dry it and calcinate it in air at 500°C for 5 hours. After grinding the obtained sample, add it to an aqueous solution of nickel nitrate with a concentration of about 0.17mol / L and stir for 24 hours Afterwards, it was dried and calcined at 500 °C in air for 5 h, and then in H 2 Reduction at 450°C for 4h.

Embodiment 2

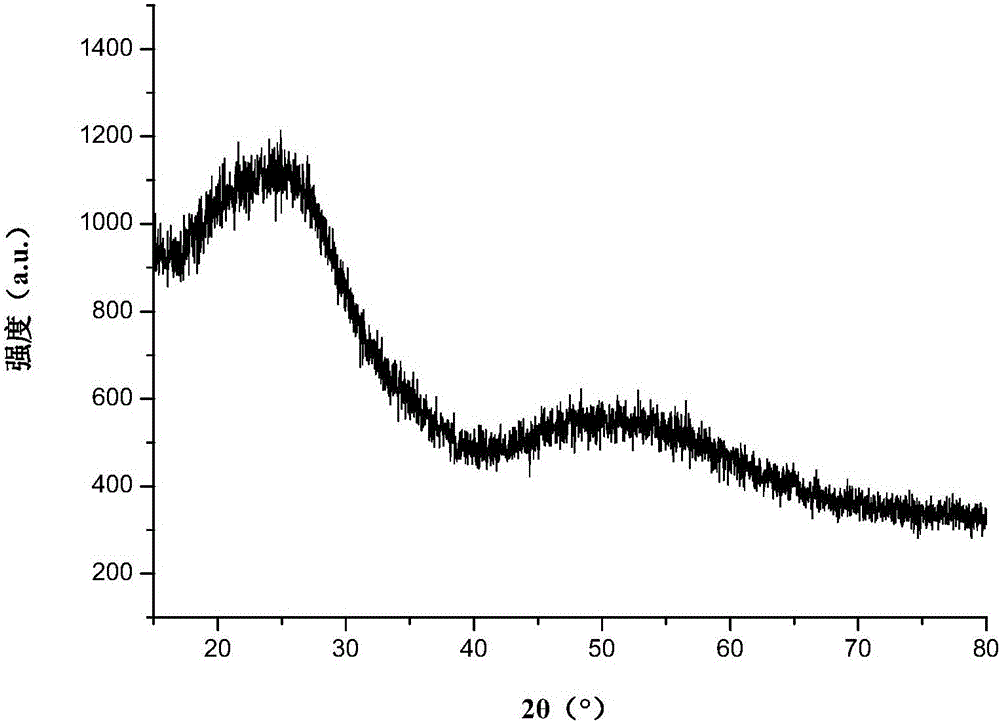

[0040] Ru / K / NbOPO 4 Catalyst preparation: 1g NbOPO 4 The powder was added to an aqueous solution of 0.008mol / L potassium oxalate and stirred for 24 hours, dried, and calcined at 400°C in air for 5 hours. The obtained sample was ground and added to an aqueous solution of 0.05mol / L ruthenium chloride, stirred for 24 hours, and Dry and reduce in hydrogen at 300°C for 3h, the XRD spectrum of the obtained catalyst is shown in figure 1 .

Embodiment 3

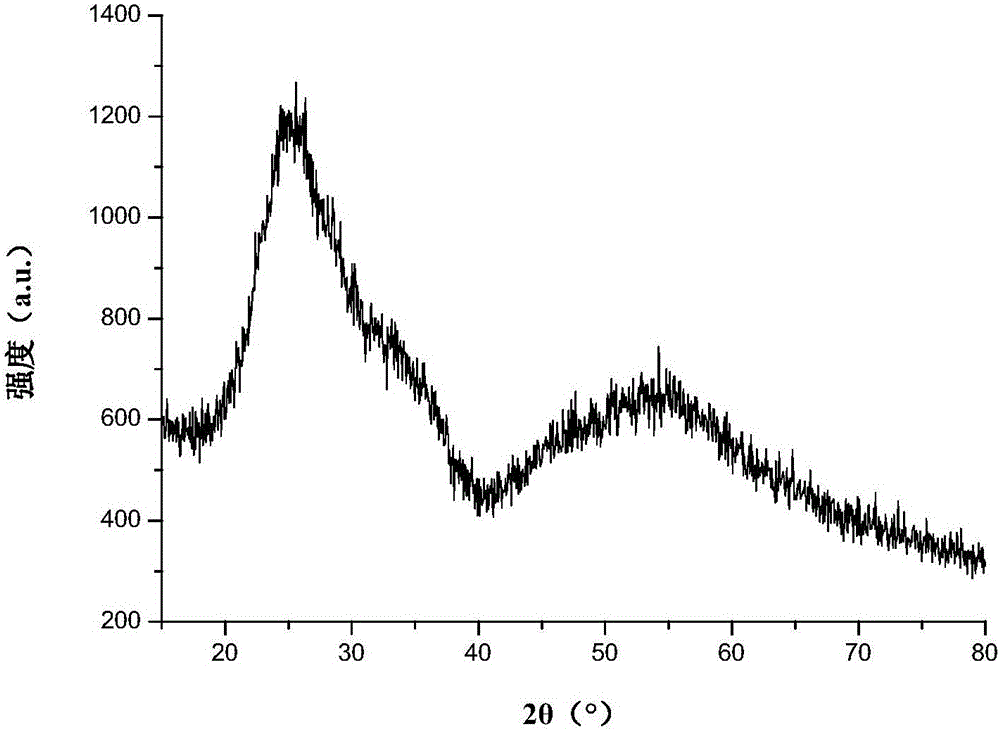

[0042] Ru / Na / Nb 2 o 5 Catalyst preparation: 1g Nb 2 o 5 The powder was added to an aqueous solution of 0.01mol / L sodium chloride and stirred for 24 hours, dried, and calcined at 300°C in the air for 3 hours. After grinding, the obtained sample was added to an aqueous solution of 0.05mol / L ruthenium chloride, and stirred for 24 hours. Drying and reducing in hydrogen at 300°C for 3h, the XRD spectrum of the obtained catalyst is shown in figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com