Front-end atomizing automatic-stretching spray gun of SNCR (Selective Non-Catalytic Reduction) system

An automatic retractable and spray gun technology, which is applied in chemical instruments and methods, gas treatment, dispersed particle separation, etc., can solve the problems of poor solution atomization effect, low atomization air pressure, and short service life, so as to reduce the downtime rate , Improve the uniformity of spraying and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

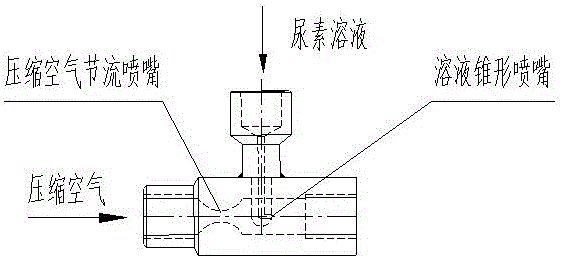

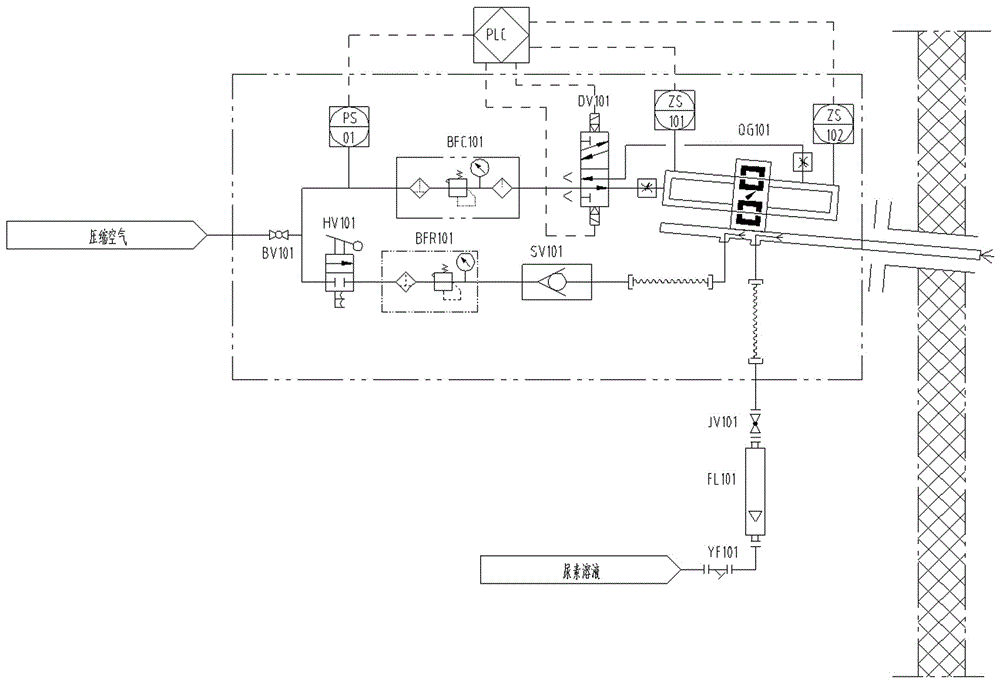

[0029] Such as figure 1 As shown, the front-end atomizing automatic retractable spray gun of the SNCR system of the present invention includes: a spray gun installation sleeve 1, a silicon carbide protective sleeve 2, a nozzle pipe 3, a nozzle 4, a sealing assembly 5, and a front-end atomization combined nozzle 6, Adjust screw rod 7, cylinder assembly 8, pneumatic assembly 9, compressed air source assembly 10, base 11.

[0030] Spray gun installation sleeve 1 is made of 304 stainless steel pipe, and the boiler designer selects a suitable position according to the smoke temperature and pre-embeds it in the furnace wall when laying the furnace wall, and is used to fix the nozzle 3.

[0031] The silicon carbide protective sleeve 2 is made of silicon carbide material resistant to high temperature, acid and alkali, and is sintered into the designed structural size through a cus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com