Circuit board

A technology of circuit boards and substrates, which is applied in the direction of printed circuits, printed circuits, circuit devices, etc., can solve the problems of signal integrity, large through-hole area of the formation, discontinuous formation, etc., to ensure integrity, reliability, The effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present application will be further described in detail below through specific embodiments in conjunction with the drawings. The "front", "rear", "left", "right", "up" and "down" mentioned in the text are all based on the placement state in the drawings.

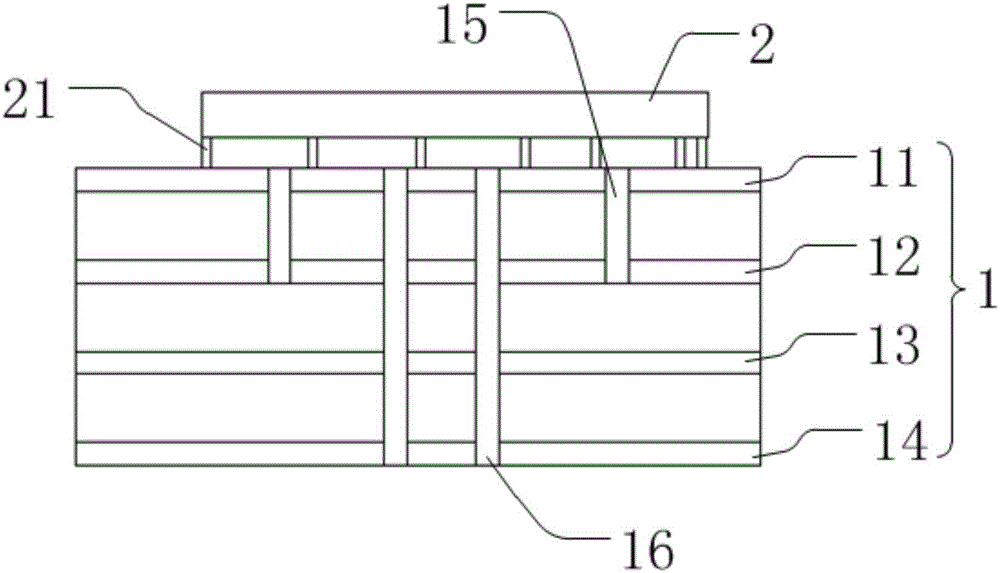

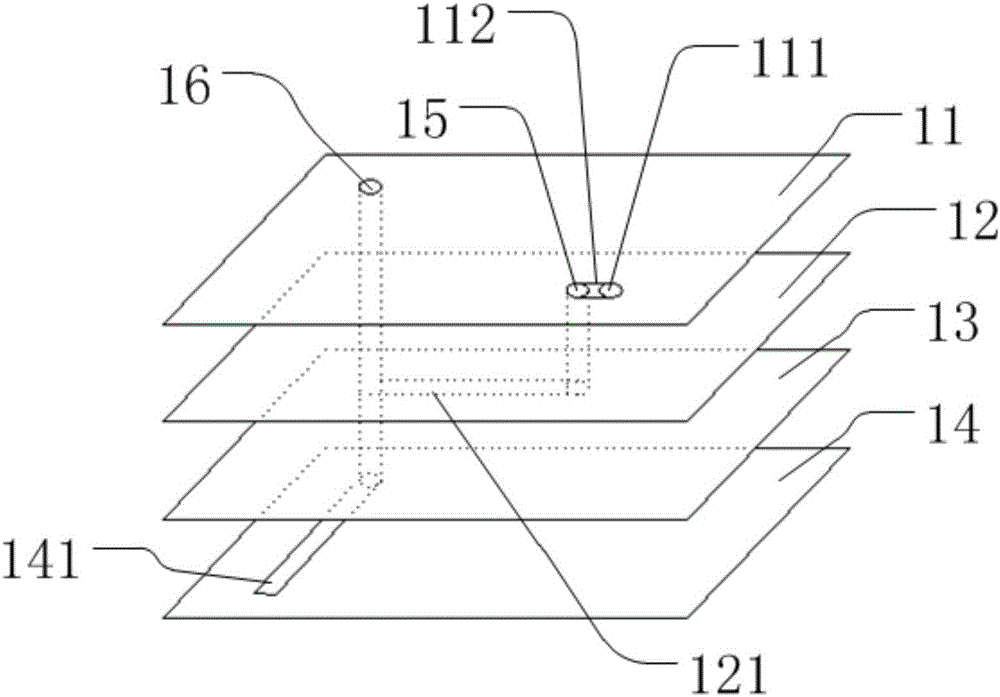

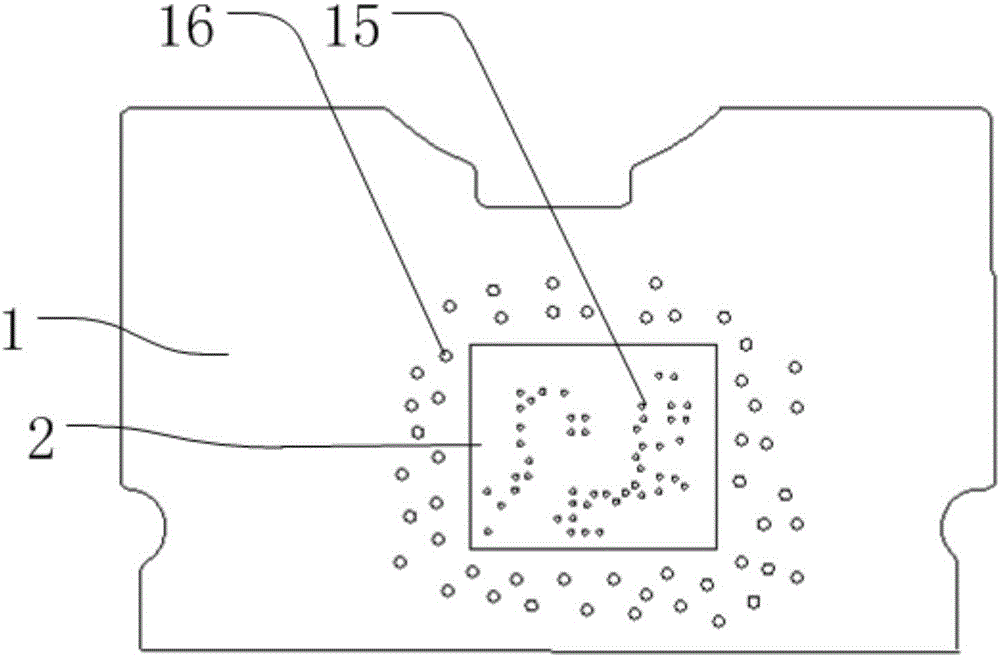

[0037] Such as Figure 1-3 As shown, the embodiment of the present application provides a circuit board including a substrate 1 and a first conductive member. The substrate 1 includes a device layer 11, a signal layer 12, and a ground layer 13, and the device layer 11, the signal layer 12, and the ground layer 13 are stacked, And the signal layer 12 is located between the device layer 11 and the ground layer 13, and the device layer 11 is provided with a plurality of pads 111; the substrate 1 is provided with a blind hole 15 which extends from the device layer 11 to the signal layer 12, that is, does not penetrate In the ground layer 13, the first conductive member is provided in the blind hole 15, that is, each bli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com