Solar cell irradiation annealing furnace

A technology for solar cells and annealing furnaces is applied in the field of irradiation annealing treatment of solar cells, which can solve the problems of not considering the cooling of cells, affecting the effect of irradiation annealing treatment, etc., so as to solve the problems of large-scale production and structure of on-line treatment. Simple, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

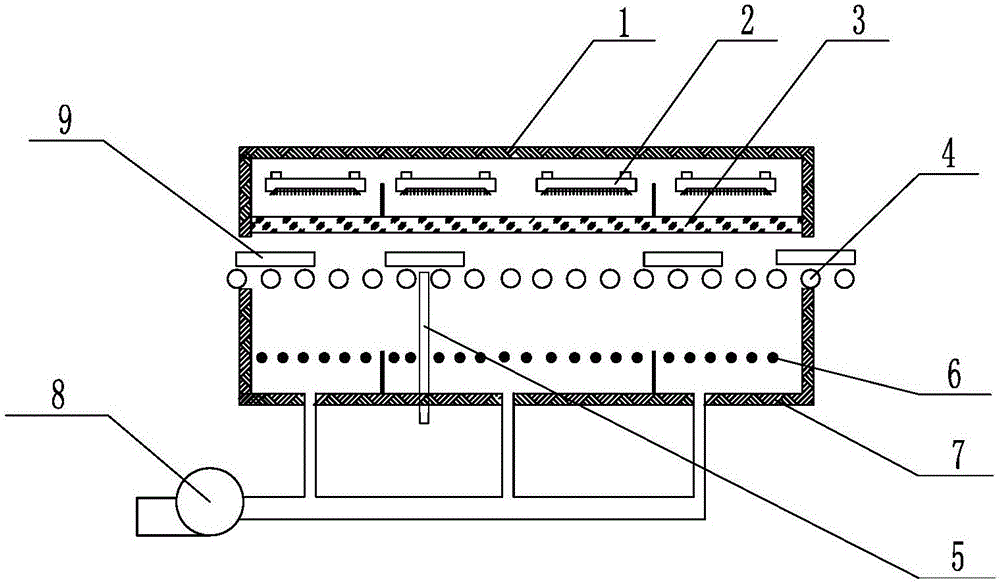

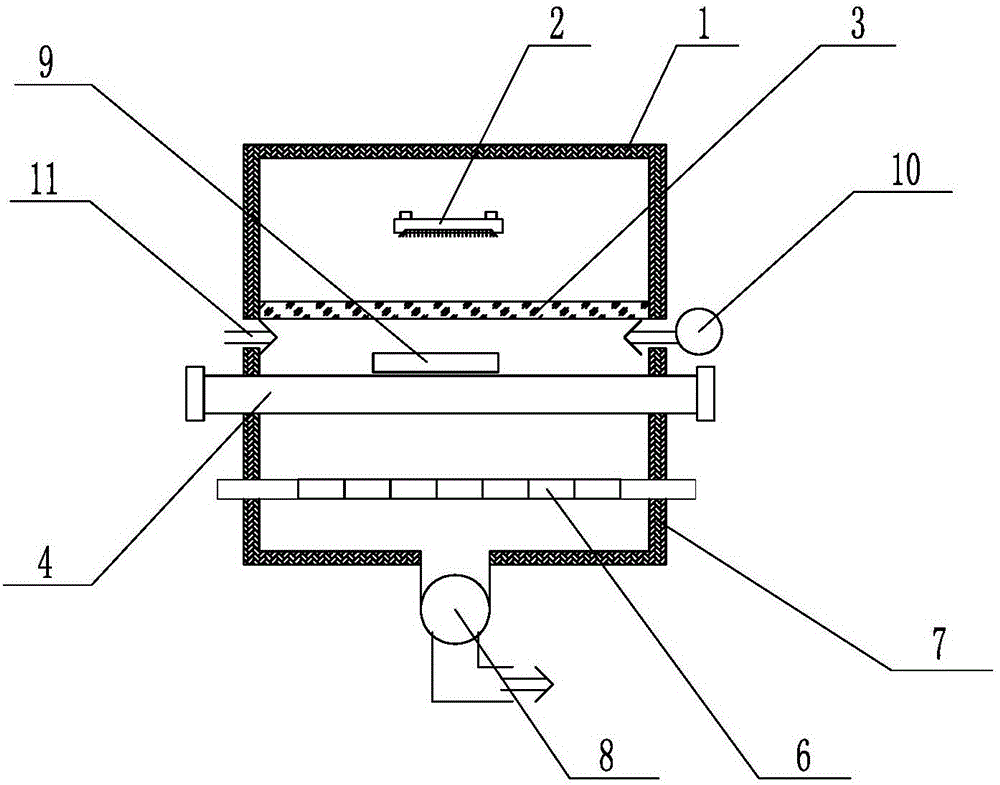

[0024] Such as Figure 1-2 As shown, the solar cell radiation annealing furnace of the present invention includes a furnace body, the furnace body includes an upper furnace body 1 and a lower furnace body 7, and the upper furnace body 1 and the lower furnace body 7 are connected by a support or a lifting mechanism, To facilitate the inspection and maintenance of the annealing furnace, a light source 2 is arranged in the upper furnace body 1, and a transparent heat insulating material layer 3 is arranged between the upper furnace body 1 and the lower furnace body 7 corresponding to the light source 2, and the cell sheet transmission device 4 and the lower furnace body 7 are arranged in the lower furnace body 7 The temperature sensor 5 and the battery sheet 9 are horizontally transmitted on the battery sheet conveying device 4 and are irradiated by the light source 2. An air inlet 11 or a blowing device 10 is arranged on the side of the furnace body between the battery sheet 9 an...

Embodiment 2

[0028] The battery sheet transport device 4 is a stainless steel mesh belt that circulates in and out of the irradiation annealing furnace, and the rest are the same as in Embodiment 1.

[0029] Working principle and use process of the present invention:

[0030] When the solar cell radiation annealing furnace is in use, turn on the light source 2, place the battery sheet 9 on the horizontally arranged ceramic roller table or on the stainless steel mesh belt that circulates in and out of the radiation annealing furnace, and pass between the upper furnace body 1 and the lower furnace body 7 A transparent heat insulating material layer 3 is set to isolate the light source 2 from the chamber in which the cells 9 are processed. The cells 9 are transported on a horizontally arranged ceramic roller table or on a stainless steel mesh belt that circulates in and out of the irradiation annealing furnace, and are received in the furnace. Irradiation of a light source 2 inside a body 1 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com