Composite conductive paste for positive and negative electrodes of lithium ion battery and preparation method thereof

A lithium-ion battery and composite conductive technology, which is applied in the direction of battery electrodes, cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of cycle life, energy density, electrochemical performance, etc. The method is simple and controllable, reducing the use and reducing the internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

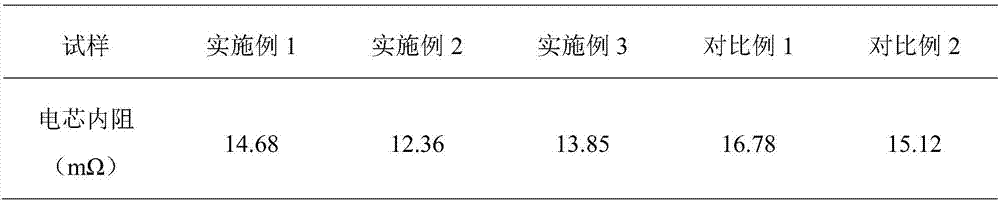

Examples

preparation example Construction

[0027] The composite conductive paste for the positive and negative electrodes of the lithium-ion battery provided in the embodiments of the present invention can be prepared by the following method, and of course, it can also be prepared by other methods that can obtain the composite conductive paste for the positive and negative electrodes of the lithium-ion battery . Correspondingly, an embodiment of the present invention also provides a method for preparing a composite conductive paste for positive and negative electrodes of a lithium ion battery, comprising the following steps:

[0028] S01. Weigh each component according to the formula of the composite conductive paste of the positive and negative electrodes of the above-mentioned lithium ion battery;

[0029] S02. dissolving the dispersant in N-methylpyrrolidone to obtain a mixed solution;

[0030] S03. After the carbon nanotubes are premixed with a mixing device, they are added to the mixed solution, and subjected to ...

Embodiment 1

[0041] A conductive paste for positive and negative electrodes of a lithium ion battery, comprising the following formulation components in the following parts by weight:

[0042] 5 parts of carbon nanotubes;

[0043] Dispersant 0.3 part;

[0044] 94.7 parts of N-methylpyrrolidone;

[0045] The carbon nanotubes are composed of large-diameter carbon nanotubes and small-diameter carbon nanotubes, wherein the diameter of the large-diameter carbon nanotubes is 30-150nm, and the diameter of the small-diameter carbon nanotubes 1-30nm, and the diameter difference between the large-diameter carbon nanotubes and the small-diameter carbon nanotubes is ≥ 15nm; the weight ratio of the large-diameter carbon nanotubes to the small-diameter carbon nanotubes is 7 :3.

[0046] The preparation method of the composite conductive paste of the positive and negative electrodes of the lithium ion battery is:

[0047] S11. Weigh each component according to the formula of the composite conductive ...

Embodiment 2

[0053] A conductive paste for positive and negative electrodes of a lithium ion battery, comprising the following formulation components in the following parts by weight:

[0054] 5 parts of carbon nanotubes;

[0055] Dispersant 0.3 part;

[0056] 94.7 parts of N-methylpyrrolidone;

[0057] The carbon nanotubes are composed of large-diameter carbon nanotubes and small-diameter carbon nanotubes, wherein the diameter of the large-diameter carbon nanotubes is 30-150nm, and the diameter of the small-diameter carbon nanotubes 1-30nm, and the diameter difference between the large-diameter carbon nanotube and the small-diameter carbon nanotube is more than or equal to 15nm; the weight ratio of the large-diameter carbon nanotube to the small-diameter carbon nanotube is 5 :5.

[0058] The preparation method of the composite conductive paste for the positive and negative electrodes of the lithium ion battery is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com