An optical projection screen for display and a manufacturing method thereof

A technology for optical projection and display, applied in optics, optical components, lenses, etc., can solve the problems that projection screens cannot achieve high luminance gain and wide viewing angle, and achieve high luminance gain and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

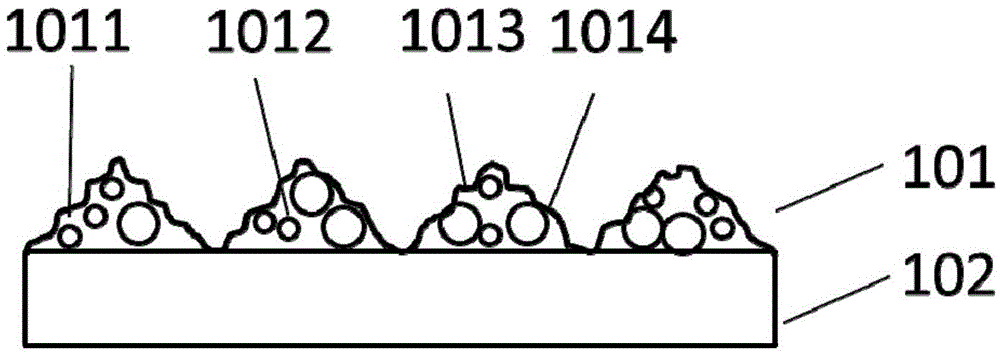

[0053] Such as figure 1 As shown, the optical projection screen for display provided by the present invention includes a prism layer 101 and a base layer 102 . The prism layer 101 is firmly bonded to the surface of the base layer 102 . The prism layer 101 includes an adhesive 1011 and reflective particles 1012 inside. The exterior of the prism layer includes a first surface 1013 and a second surface 1014 .

[0054] PET with a thickness of 250 μm was selected as the base layer. The prism layer is fabricated on the base layer by using an adhesive (component: acrylic resin) containing reflective particles (a mixture of aluminum silver powder and titanium dioxide at a weight ratio of 1:1). The parts by weight of the reflective particles are 50 parts by weight, and the parts by weight of the adhesive are 100 parts by weight. The size of the reflective particles is 1-10 μm.

[0055] The light concentrating microstructures included in the prism layer are prism strips. The prism...

Embodiment 2

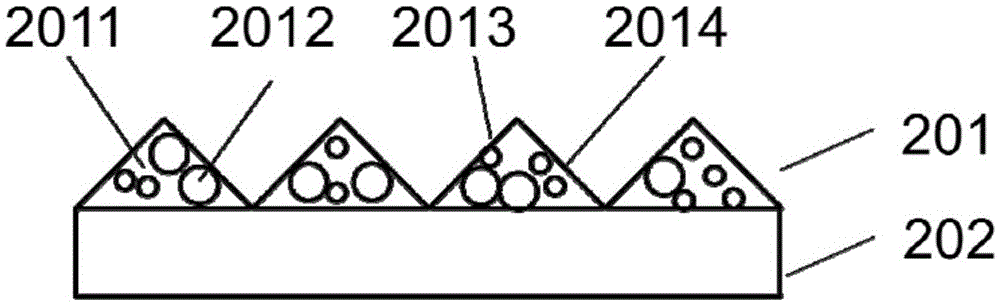

[0057] Such as figure 2 As shown, the present invention selects PET with a thickness of 200 μm as the base layer. Use an adhesive (ingredient: polyurethane resin) containing reflective particles (ingredient: titanium dioxide) to make a prism layer on the base layer, the prism layer contains 10% microporous structure, and the micropore size is 10-20 μm , has the effect of reflecting light. The parts by weight of the reflective particles are 20, and the parts by weight of the adhesive are 100 parts by weight.

[0058] The microprism structures included in the prism layer are prism strips. The prism strips are dithering, the apex angle formed by the first surface and the second surface is 80°, and the shape of the apex angle is arc-shaped. The height of the prism bars in the prism bar array is inconsistent, and the height of the prism bars is 200-250 μm. Both the first surface and the second surface of the prism strip are smooth surfaces.

Embodiment 3

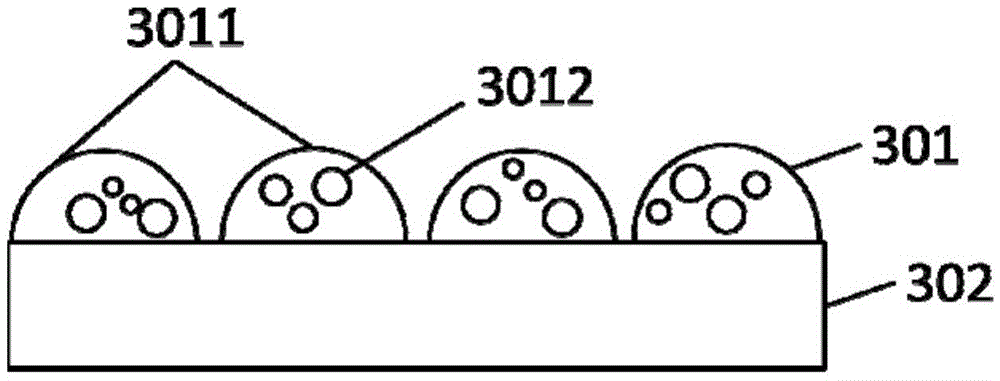

[0060] The present invention provides an optical projection screen for display, wherein, such as image 3 As shown, a non-woven fabric with a thickness of 1 cm was selected as the base layer. An adhesive (component: acrylic resin) containing reflective particles (a mixture of aluminum oxide and barium sulfate at a weight ratio of 1:2) is used to fabricate a microlens layer on the base layer. The parts by weight of the reflective particles are 80 parts by weight, and the parts by weight of the adhesive are 100 parts by weight.

[0061] The diameter of a single structure in the microlens layer is 300 μm, and the distance between the single structures is 200-300 μm. The surface of the microlens array is uneven, and the surface roughness is 0.01-0.1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com