a brightening film

A technology of brightness-enhancing film and light-gathering layer, which is applied in the direction of diffusing elements, can solve the problems that the incremental effect needs to be improved, and achieve the effects of reducing the number of sheets used, high luminance gain, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

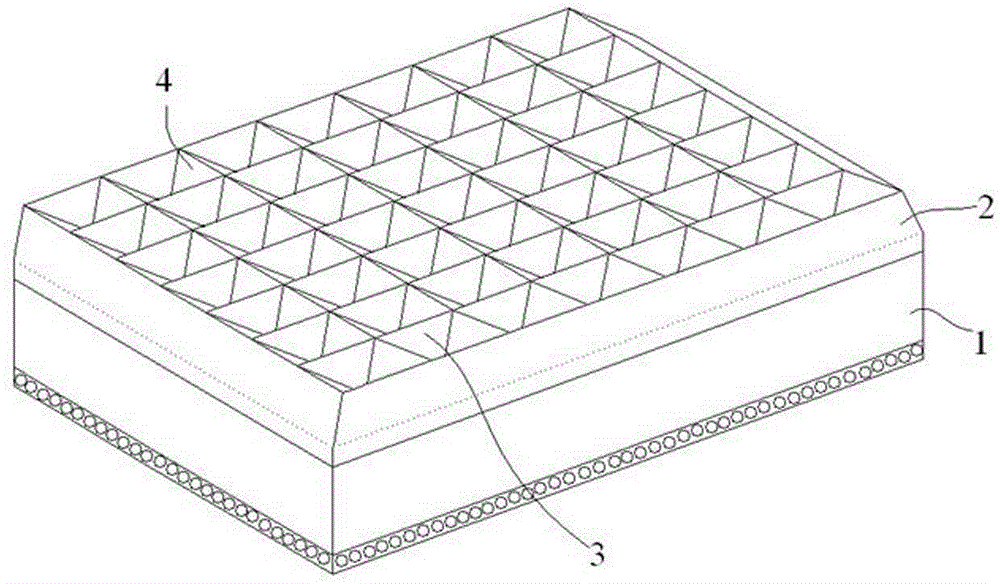

Embodiment 1

[0018] A brightness enhancement film includes a substrate layer 1 and a light-concentrating layer 2. The surface of the light-concentrating layer 2 has a concave-convex structure in both the length direction and the width direction of the brightness enhancement film. In this embodiment, the concave-convex structure is specifically: on the surface of the light-concentrating layer 2, there are partitions 3 parallel to each other along the length direction of the brightness enhancement film, and an interlayer is formed between adjacent partitions 3, The interlayer has a row of triangular prisms 4 to form a row of triangular prisms, each of the triangular prisms 4 has the same shape, and the two triangular bottom surfaces of the triangular prisms 4 are integrated with the partition 3; the triangular prisms in each interlayer The rows all correspond to each other to form rows of triangular prisms in the width direction of the brightness enhancement film. The upper corners of the tri...

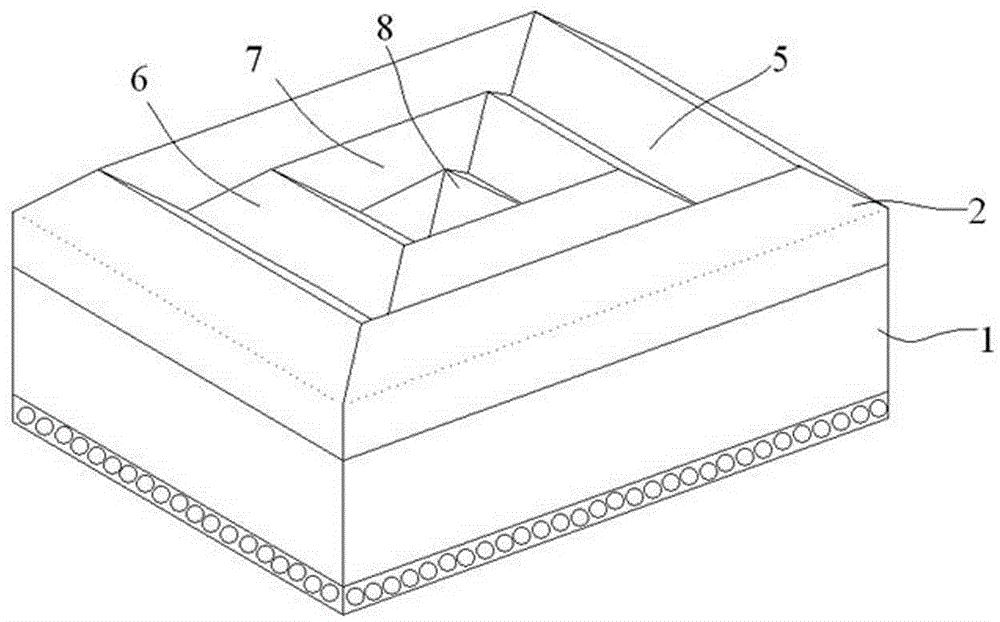

Embodiment 2

[0023] A brightness enhancement film includes a substrate layer 1 and a light-concentrating layer 2. The surface of the light-concentrating layer 2 has a concave-convex structure in both the length direction and the width direction of the brightness enhancement film. In this embodiment, the concave-convex structure is specifically as follows: the surface of the light-concentrating layer 2 has a regular quadrangular truncated trough-shaped lower groove 5, and the inner side of the lower groove is inclined inward;

[0024] The bottom surface of the lower groove 5 protrudes upwardly with a regular quadrangular pyramid-shaped boss 6, and the four sides of the boss 6 are inclined inward;

[0025] The upper surface of the boss 6 has a downward concave central groove 7 in the shape of a quadrangular pyramid, the inner side of the central groove 7 is inclined inward and the central groove 7 shares a bottom surface with the lower groove 5;

[0026] The bottom surface of the central groove 7 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com